Abstract

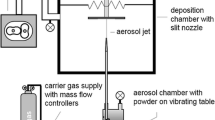

The work is devoted to the study of electrical properties (temperature dependences of conductivity, relative dielectric constant, dielectric loss tangent for various frequencies) of an aluminum oxide ceramic film deposited on a metal substrate. The film was created by an original method of electron beam evaporation of a nonconducting target consisting of a compressed alumina powder using a plasma electron source, which is able to reliably operate in the fore-vacuum pressure range (5–100 Pa). Such increased working gas pressure ensures the generation of a dense beam plasma near the target, which neutralizes the charging of a nonconducting target and thereby provides its effective melting and electron beam evaporation.

Similar content being viewed by others

REFERENCES

Koritskii, Yu.V., Pasynkov, V.V., and Tareev, B.M., Spravochnik po elektrotekhnicheskim materialam (Handbook on Materials for Electrical Engineering), Moscow: Energiya, 1987, vol. 2.

Bogorodickii, N.P., Pasynkov, V.V., and Tareev, B.M., Elektrotekhnicheskie materialy: Uchebnik dlya vuzov (Electrotechnical Materials: Handbook for Universities), Leningrad: Energoatomizdat, 1985.

Yushkov, Yu.G., Oks, E.M., Tyunkov, A.V., and Zolotukhin, D.B., Alumina coating deposition by electron-beam evaporation of ceramic using a forevacuum plasma-cathode electron source, Ceram. Int., 2019, vol. 45, no. 8, pp. 9782–9787.

Burdovitsin, V.A., Klimov, A.S., Medovnik, A.V., Oks, E.M., and Yushkov, Yu.G., Forvacuumnye plazmennye istochniki elektronov (Forevacuum Plasma Electron Sources), Tomsk: Tomsk State Univ., 2014.

Zenin, A., Bakeev, I., Burachevsky, Yu., Klimov, A., Oks, E., and Yushkov, Yu., Forevacuum plasma electron source for dielectric surface treatment, Proc. 20th Int. Symp. on High-Current Electronics (ISHCE), Tomsk, Russia, September 16–22, 2018, pp. 43–45.

Kurilenko, O.D., Kratkii spravochnik po khimii (Quick Reference to Chemistry), Kiev: Naukova Dumka, 1974.

Kikoin, I.K., Tablitsy fizicheskikh velichin (Tables of Physical Quantities), Moscow: Atomizdat, 1976.

Yushkov, Yu.G., Burachevsky, Yu.A., Zolotukhin, D.B., Oks, E.M., Tyunkov, A.V., and Yushkov, A.Yu., Parameters and properties of electro-insulating alumina coating deposited on metal by forevacuum source, Prikl. Fiz., 2020, no. 2, pp. 53–58.

Yushkov, Yu.G., Zolotukhin, D.B., Tyunkov, A.V., and Oks, E.M., Ceramic coating deposition by electron beam evaporation, Surf. Coat. Technol., 2017, vol. 325, pp. 1–6.

Skanavi, G.I., Fizika dielektrikov (oblast’ slabykh polei) (Dielectric Physics (Strong-Field Region)), Moscow–Leningrad: Tekh. Literatura, 1949.

Funding

The work on deposition and study of the electrical insulating properties of coatings was carried out with the support of the Russian Foundation for Basic Research, project no. 18-08-00539 A. The work on the study of evaporation processes of dielectric targets was supported by the Grant of the President of the Russian Federation (no. MK-154.2020.8).

Author information

Authors and Affiliations

Corresponding authors

Additional information

Translated by Sh. Galyaltdinov

Rights and permissions

About this article

Cite this article

Bakeev, I.Y., Burachevsky, Y.A., Dvilis, E.S. et al. Electrical Properties of Aluminum Oxide Ceramics Film on a Metal. Inorg. Mater. Appl. Res. 12, 1276–1280 (2021). https://doi.org/10.1134/S207511332105004X

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S207511332105004X