Abstract

This article discusses interaction between reagents and stainless steel substrate upon deposition of tantalum coating by reduction of tantalum bromide with cadmium. It has been established that, at deposition temperatures higher than 1000 K, iron and chromium in stainless steel will reduce tantalum pentabromide, transferring into the gas phase in the form of bromides. As a consequence, not only tantalum bromide is reduced on the substrate but also iron bromide, which leads to formation of sublayer containing iron in the coating. An increase in the surface area of stainless steel interacting with reagents leads to an increase in the content of iron bromide, and in this case, the coating is formed from the mixture of Ta + Fe2Ta. In addition, chromium bromide is formed on the substrate, which is removed together with other reaction products, resulting in depletion of chromium in steel surface layers.

Similar content being viewed by others

REFERENCES

Laurila, T., Zeng, K., and Kivilahti, J.K., Effect of oxygen on the reactions in the Si/Ta/Cu metallization system, J. Mater. Res., 2001, vol. 16, no. 10, pp. 2939–2946.

Matson, D.W., McClanahan, E.D., Lee, S.L., and Windover, D., Properties of thick sputtered Ta used for protective gun tube coatings, Surf. Coat. Technol., 2001, vols. 146/147, pp. 344–350.

Cristea, D., Ghiuta, I., and Munteanu, D., Tantalum based materials for implants and prostheses applications, Bull. Transilvania Univ. Brasov, Ser. I, 2015, vol. 8, no. 2, pp. 151–158.

Gambale, D., Tantalum surface alloys prevent corrosion, Adv. Mater. Processes, 2010, no. 6, pp. 23–25.

Parsapour, A., Khorasani, S.N., and Fathi, M.H., Effect of surface treatment and metallic coating on corrosion behavior and biocompatibility of surgical 316L stainless steel implant, J. Mater. Sci. Technol., 2012, vol. 28, no. 2, pp. 125–131.

Kaloyeros, A.E., Chen, X., Lane, S., and Frisch, H.L., Tantalum diffusion barrier grown by inorganic plasma-promoted chemical vapor deposition, J. Mater. Res., 2000, vol. 15, no. 12, pp. 2800–2810.

Chemical Vapour Deposition: Precursors, Processes and Applications, Hitchman, M.L. and Jones, A.C., Eds., Cambridge: Royal Soc. Chem., 2009.

Goncharov, O.Yu., Faizullin, R.R., Guskov, V.N., and Baldaev, L.Kh., Thermodynamic analysis of Ta chemical vapor deposition via the reduction of tantalum halides with cadmium and zinc, Inorg. Mater., 2015, vol. 51, no. 6, pp. 593–597.

Goncharov, O.Yu., Il’in, I.A., Titorov, D.B., and Tito-rova, D.V., Textures of coatings molybdenum, tantalum and boride hafnium obtained by chemical gas phase deposition, Perspekt. Mater., 2008, no. 4, pp. 69–73.

Goncharov, O.Yu., Treshchev, S.Y., Ladiyanov, V.I., Faizullin, R.R., Guskov, V.N., and Baldaev, L.Kh., Tantalum chemical vapor deposition on substrates from various materials, Inorg. Mater., 2017, vol. 53, no. 10, pp. 1064–1068.

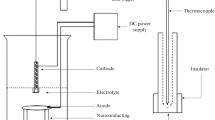

Goncharov, O.Yu., Faizullin, R.R., Gus’kov, V.N., and Baldaev, L.Kh., Equipment for the hydrogen-free chemical vapor deposition of oxygen-free refractory materials, Izv. Akad. Inzhen. Nauk im. A.M. Prokhorova, 2015, no. 4, pp. 3–9.

Shelekhov, E.V. and Sviridova, T.A., Programs for X‑ray analysis of polycrystals, Met. Sci. Heat Treat., 2000, vol. 42, no. 8, pp. 309–313.

Read, M.H. and Altman, C.A., New structure in tantalum thin films, Appl. Phys. Lett., 1965, vol. 7, no. 3, pp. 51–52.

Lee, S.L., Doxbeck, M., and Mueller, J., Texture, structure and phase transformation in sputter beta tantalum coating, Surf. Coat. Technol., 2004, vols. 177–178, pp. 44–51.

Goncharov, O.Yu., Faizullin, R.R., Guskov, V.N., and Baldaev, L.Kh., Analysis of interaction between reactants and substrate materials during the growth of tantalum coatings, Inorg. Mater., 2016, vol. 52, no. 3, pp. 274–278.

Diagrammy sostoyaniya dvoinykh metallicheskikh sistem (State Diagrams of Double Metallic Systems), Lyakishev, N.P., Ed., Moscow: Mashinostroenie, 1997.

Guoqing, C., Binggang, Z., Yuan, Z., Binghui, D., and Jicai, F., Microstructure and properties of electron beam welded tantalum-to-stainless steel joints, Rare Met. Mater. Eng., 2013, vol. 42, no. 5, pp. 914–918.

Masumoto, H., Asada, A., Hasuyama, H., Nishio, K., Kato, M., and Mukae, S., Diffusion bonding of tantalum and stainless steel, Weld. Int., 1997, vol. 11, no. 2, pp. 110–120.

Sapegina, I.V., Goncharov, O.Yu., Lad’yanov, V.I., and Baldaev, L.Kh., Influence of deposition conditions on the composition of tantalum coatings, Letters on Materials, 2019, vol. 9, no. 1, pp. 22–26.

Funding

This work was supported by the Ministry of Science and Higher Education of the Russian Federation, project no. AAAA-A17-117022250039-4. The studies performed using equipment of the Shared Use Centre “Centre of Physical and Physicochemical Methods of Analysis and Study of the Properties and Surface Characteristics of Nanostructures, Materials, and Products” UdmFRC UB RAS supported by Russian Ministry of Science and Education, unique project ID: RFMEFI62119X0035.

Author information

Authors and Affiliations

Corresponding authors

Additional information

Translated by I. Moshkin

Rights and permissions

About this article

Cite this article

Sapegina, I.V., Goncharov, O.Y. & Ladyanov, V.I. Analysis of Layer Composition Formed on Stainless Steel Substrates upon Chemical Vapor Deposition of Tantalum. Inorg. Mater. Appl. Res. 12, 731–734 (2021). https://doi.org/10.1134/S2075113321030333

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S2075113321030333