Abstract

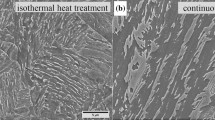

The results of studies on the effects of tempering temperature on the static strength and crack resistance of 38KhN3MFA-Sh steel are presented. The fractured surface texture has been studied after different heat treatment modes using electron fractography analysis. Relationships between the fracture characteristics and the critical stress intensity factor have been established. The effect of tempering temperature on the velocities of ultrasonic bulk waves has been investigated. A linear relationship between the velocity of elastic waves and the critical stress intensity factor of 38KhN3MFA-Sh steel has been found. The revealed relationship makes it possible to estimate the changes in crack resistance of steel using a nondestructive testing method with variations in the tempering temperature. The method of electron fractography has been used to analyze the fractures in the samples of structural high-quality 38KhN3MFA-Sh steel with a crack. The investigations of the fractured surface texture after different heat-treatment modes have shown that the microrelief is represented by flattened cone-shaped pits. The increase in the tempering temperature is accompanied by an increase in the diameter of flattened pit-cones on the fracture surface. A quadratic relationship between the crack resistance parameter and the diameter of the pits has been revealed. It has been shown that the contribution of the structural condition of the ferrite matrix to crack resistance is much more significant than the contribution of isolated carbides. The elastic wave velocities in steel have been measured; their values exhibit an increase with an increase in the tempering temperature. The strength and crack resistance parameters of the structural steel exposed to high-temperature tempering have been predicted on the basis of the values of transverse wave velocities. The deviations of the predicted values of crack resistance K1c and ultimate strength σu from the experimental values do not exceed 5.4 and 12.6%, respectively.

Similar content being viewed by others

REFERENCES

Vladimirov, V.I., Fizicheskaya priroda razrusheniya metallov (Physical Nature of Destruction of Metals), Moscow: Metallurgiya, 1984, p. 264.

Gross, D. and Seelig, T., Fracture Mechanics: With an Introduction to Micromechanics, Berlin: Springer-Verlag, 2011, p. 74.

Murav’ev, V.V., Zuev, L.B., and Komarov, K.L., Skorost’ zvuka i struktura stalei (Acoustic Speed and Structure of Steel), Novosibirsk: Nauka, 1996, p. 43.

Raj, B., Moorthy, V., Jayakumar, T., Rao, K.B.S., Assessment of microstructures and mechanical behavior of metallic materials through non-destructive characterization, Int. Mater. Rev., 2003, vol. 48, no. 5, pp. 273–325.

Droney, B.E. and Klinman, R., Ultrasonic techniques for determining the mechanical properties of steel, AIP Conf. Proc., 1982, vol. 84, p. 210. https://doi.org/10.1063/1.33537

Pavlov, A.M., Pavlov, A.V., Zhilkashinova A.M., and Satbaeva Z.A. Studies of the relationship of the speed of ultrasound with the mechanical properties of cast steel, Tekh. Nauki–Teor. Prakt., 2016, vol. 56, no. 8, pp. 60–68.

Botaki, A.A., Ul’yanov, V.L., and Sharko, A.B., Ultra-zvukovoi kontrol’ prochnostnykh svoistv konstruktsionnykh materialov (Ultrasonic Testing of Strength Properties of Construction Materials), Moscow: Mashinostroenie, 1983, p. 11.

Goldstein, J., Newbury, D.E., Echlin, P., Joy, D.C., Romig, A.D., Jr., Lyman, C.E., Fiori, C., and Lifshin, E., Scanning Electron Microscopy and X-ray Microanalysis, New York: Springer-Verlag, 1992.

Krishtal, M.M., Yasnikov, I.S., and Polunin, V.I., Skaniruyushchaya elektronnaya mikroskopiya i rentgenovskii mikroanaliz v primerakh prakticheskogo primeneniya (The Scanning Electronic Microscopy and the X-ray Microanalysis in Examples of Practical Application), Krishtal, M.M., Ed., Moscow: Tekhnosfera, 2009, p. 34.

Kireeva, E.Yu. and Izotov, V.I., Investigation of the specific features of brittle fracture of carbon steel in various structural states using scanning electron microscopy of a slightly etched fracture surfaces, Phys. Met. Metallogr., 2011, vol. 112, no. 3, pp. 301–308.

Goldstein, J.I. and Yakowitz, H., Practical Scanning Electron Microscopy, New York: Plenum, 1975.

Gulyaev, A.P. and Gulyaev, A.A., Metallovedenie (Metal Science), Moscow: Al’yans, 2011.

Kurdyumov, G.V., Yavleniya zakalki i otpuska stali (Steel Hardening and Tempering), Moscow: Metallurg-izdat, 1960, p. 53.

Shaimanov, G.S., Simonov, M.Yu., and Simonov, Yu.N., The destruction of surface of 09G2S steel after cold radial forging, Vestn. Perm. Nats. Issled. Politekh. Univ., Mashinostr., Materialoved., 2016, vol. 18, no. 3, pp. 119–134.

Georgiev, M.N., Lipchin, N.N., and Simonov, Yu.N., Connection of the metal structure with the fractographic features of the surface of fatigue fractures, Fiz. Met. Metalloved., 1987, vol. 63, no. 3, pp. 622–624.

Grigorenko, V.B., Morozova, L.V., and Orlov, M.R. Investigation of the causes of the appearance of areas with different fracture morphology in forged billets made of steel 38KhN3MFA, Tr. VIAM, 2014, no. 8, p. 11.

Botvina, L.R., Razrushenie. Kinetika, mekhanizmy, obshchie zakonomernosti (Destruction: Kinetics, Mechanisms, and General Patterns), Moscow: Nauka, 2008, p. 25.

Georgiev, M.N., Dogadushkin, V.Yu., Mezhova, N.Ya., Minaev, V.N., and Strok, L.P., Relationship of fatigue crack growth rate in St.3sp steel to the dimensions and orientation of the sample, Sov. Mater. Sci., 1982, vol. 17, no. 3, pp. 213–218.

Belousov, M.V., Cherepin, V.T., and Vasil’ev, M.A., Prevrashcheniya pri otpuske stali (Transformations during Steel Tempering), Moscow: Metallurgiya, 1973, p. 32.

Souissi, M. and Numakura, H., Elastic properties of Fe–C and Fe–N martensites, ISIJ Int., 2015, vol. 55, no. 7, pp. 1512–1521.

Vorob’ev, R.A., Evstifeeva, V.V., Litovchenko, V.N., Mishakin, V.V., and Dubinskii, V.N., Application of ultrasonic diagnostics for assessment of crack resistance of steel 38HN3MFA, Zavod. Lab., Diagn. Mater., 2018, vol. 84, no. 2, pp. 64–69.

Novikov, I.I., Teoriya termicheskoi obrabotki metallov (Theory of Heat Treatment of Metals), Moscow: Metallurgiya, 1978, p. 305.

Funding

This work was financially supported within the framework of the state assignment of the Institute of Applied Physics of the Russian Academy of Sciences for fundamental scientific research for 2013–2020 no. 0035-2014-0402, state registration number 01201458047.

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated by O. Polyakov

Rights and permissions

About this article

Cite this article

Evstifeeva, V.V., Litovchenko, V.N., Mishakin, V.V. et al. Crack Resistance Evaluation for 38KhN3MFA-Sh Structural Steel According to Fracture Characteristics and Elastic Wave Velocities. Inorg. Mater. Appl. Res. 11, 1439–1446 (2020). https://doi.org/10.1134/S2075113320060052

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S2075113320060052