Abstract

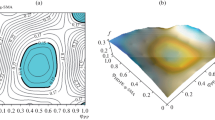

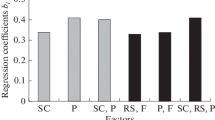

In the manufacture of products instead of unfilled polymers, such as ultra-high-molecular-weight polyethylene (UHMWPE), it is more effective to use composite systems with reinforcing inclusions. The paper discusses the possibility of creating a composition with the given physical and mechanical properties. An approach to the determination of control parameters (phase composition, phase properties) giving the material the specified effective properties or their entry into predetermined intervals is proposed. In accordance with this approach, on the basis of the analysis of experimental data containing information about the effective characteristics depending on the values of the control parameters, the corresponding surfaces of the response of physical and mechanical characteristics to the values of the control parameters are constructed in the state space. The obtained surfaces make it possible to identify the range of control parameters for the given characteristics of multicomponent polymer compositions based on UHMWPE.

Similar content being viewed by others

REFERENCES

Galetz, M.C., Blar, T., Ruckdaschel, H., Sandler, K.W., and Alstadt, V., Carbon nanofibre-reinforced ultrahigh molecular weiht polyethylene for tribological applications, J. Appl. Polym. Sci., 2007, vol. 104, pp. 4173–4181.

Wei, Z., Zhao, Y.-P., Ruan, S.L., and Gao, P., A study of the tribological behavior of carbon-nanotube-reinforeed ultrahigh molecular weight polyethylene composites, Surf. Interface Anal., 2006, vol. 38, pp. 883–886.

Yudin, A.S., Buyaev, D.I., Krasnov, A.P., Sachek, B.Ya., Afonicheva, O.V., and Bazhenova, V.B., Disperse fillers in tribological fiber-reinforced polymer materials: exploratory research, Vopr. Materialoved., 2012, no. 4, pp. 231–239.

Panin, S.V., Kornienko, L.A., Sondghaitam, N., Ivanova, L.R., and Shil’ko, S.V., Abrasive wear of micro- and nanocomposites based on super-high-molecular polyethylene (SHMPE). Part 1. Composites based on shmpe filled with microparticles AlO(OH) and Al2O3, J. Frict. Wear, 2012, vol. 33, no. 5, pp. 381–387.

Panin, S.V., Kornienko, L.A., Sondghaitam, N., Ivanova, L.R., and Shil’ko, S.V., Abrasive wear of micro- and nanocomposites based on ultra-high-molecular-weight polyethylene (UHMWPE): Part 2. Composites based on UHMWPE filled by nanoparticles and nanofibers, J. Frict. Wear, 2012, vol. 33, no. 6, pp. 453–459.

Panin, S.V., Kornienko, L.A., Sergeev, V.P., Sonjaitham, N., and Tchaikina, M.V., Wear-resistant ultrahigh-molecularweight polyethylene-based nano- and microcomposites for implants, J. Nanotechnol., 2012, vol. 2012, art. ID 729756.

Panin, S.V., Kornienko, L.A., Nguen Suan, T., Ivanova, L.R., Poltaranin, M.A., and Shil’ko, S.V., Wear resistance of composites based on ultrahigh molecular weight polyethylene filled with graphite and molybdenum disulfide microparticles, J. Frict. Wear, 2014, vol. 35, no. 4, pp. 290–296.

Krasnov, A.P., Aderikha, V.N., Afonicheva, O.V., Mit’, V. A., Tikhonov, N.N., Vasil’kov, A.Yu., Said-Galiev, E.E., Naumkin, A.V., and Nikolaev, A.Yu., Categorization system of nanofillers to polymer composites, J. Frict. Wear, 2010, vol. 31, no. 1, pp. 68–80.

Anokhina, N.Yu., Matolygina, N.Yu., Lyukshin, B.A., and Lyukshin, P.A., Computer aided design of a filled polymer composition with required stress-strain properties, Mekh. Kompoz. Mater. Konstr., 2009, vol. 15, no. 4, pp. 600–609.

Bochkareva, S.A., Grishaeva, N.Yu., Lyukshin, B.A., Lyukshin, P.A., Matolygina, N.Yu., and Panov, I.L., Obtaining of specified effective mechanical, thermal, and electrical characteristics of composite filled with dispersive materials, Inorg. Mater.: Appl. Res., 2017, vol. 8, no. 5, pp. 651–661.

ACKNOWLEDGMENTS

This work was supported by the Program of Basic Scientific Research of the State Academies of Sciences for 2013–2020 in the direction of fundamental research 23.1 [R&D registration number AAAA-A16-116122010041-9].

Author information

Authors and Affiliations

Corresponding authors

Additional information

Translated by Sh. Galyaltdinov

Rights and permissions

About this article

Cite this article

Panin, S.V., Grishaeva, N.Y., Lyukshin, P.A. et al. Receiving the Recipe of the Compositions Based on UHMWPE with the Assigned Properties. Inorg. Mater. Appl. Res. 10, 299–304 (2019). https://doi.org/10.1134/S2075113319020321

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S2075113319020321