Abstract

The article describes a new algorithm for predicting the structure of a reinforcing phase at heat treatment of high carbon steels. This approach is based on the construction of the distribution function of grains in their size for a set of regions in which the temperature gradient is sufficiently small. The proposed algorithm makes it possible to avoid calculating formation and growth of a single embryo and to proceed to modeling the structure in a relatively large cell, which can significantly reduce computational costs. To solve the problem of determining the distribution function of temperature fields, it is proposed to use a new approach based on integral heat transfer equations; this allows, on one hand, estimating the accuracy of calculations by the mismatch vector and, on the other hand, averaging thermophysical characteristics in a natural way and solving the problem on large-scale grid splits. Owing to the nonlinearity of the task and the need to use iterative procedures, integral equations provide the necessary conditions for their convergence. As a result of creating specialized software and carrying out a series of numerical calculations, it is possible to theoretically determine the necessary conditions for heat treatment for products made from steel of a particular grade: size and power of the heating inductor, the speed of its movement, the type of coolant and its feed rate, the depth of the hardened layer, etc.; as a result, this will make it possible to determine in advance the structure of the heat-treatable layer and reduce the total costs of experimental work.

Similar content being viewed by others

REFERENCES

Rudskoi, A.I. and Kolbasnikov, N.G., Physical and mathematical modeling of the formation of the structure and properties of steel during hot rolling. Development of modern steel hot rolling technologies with certain level of mechanical properties, Materialy 6-i mezhdunarodnoi molodezhnoi nauchno-prakticheskoi konferentsii “Innovatsionnye tekhnologii v metallurgii i mashinostroenii” (Proc. 6th Int. Youth Sci.-Pract. Conf. “Advanced Technologies in Metallurgy and Machine Engineering”), Yekaterinburg: Ural. Gos. Univ., 2012, pp. 331–344.

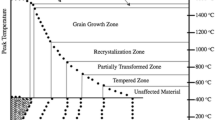

Gvozdev, A.E., Sergeyev, N.N., Minayev, I.V., et al., Temperature distribution and structure in the heat-affected zone for steel sheets after laser cutting, Inorg. Mater.: Appl. Res., 2017, vol. 8, no. 1, pp. 148–152.

Lazarson, E.V., Mathematical modeling of the structure of high-alloy steels by the Potak–Sagalevich diagram, Met. Sci. Heat Treat., 2016, vol. 58, nos. 7–8, pp. 498–501.

Ivashko, A.I., Karyakin, I.Yu., and Zyurkalov, A.A., The kinetics of structural transformations in continuous cooling of steel, Vestn. Tyumen. Gos. Univ., 2012, no. 5, pp. 54–59.

Krishtal, M.A., Tikhonov, A.K., Evmenova, Zh.L., Borgardt, A.A., and Sardaev, M.I., Atlas mikrostruktur uglerodistykh stalei (Atlas of Microstructures of Carbon Steels), Tolyatti: Tolyat. Politekh. Inst., 1988.

Svetushkov, N.N., The method in multidimensional unsteady heat conduction problems, Inf. Tekhnol., 2014, no. 12, pp. 14–19.

Svetushkov, N.N., Parallel strings method for the numerical solution of nonlinear heat conduction problem, Inf. Tekhnol., 2015, vol. 21, no. 9, pp. 689–693.

Svetushkov, N.N., Integral approach for the numerical modeling quenching process of forming rolls, Proc. CHT-15 ICHMT 6th Int. Symp. on Advances in Computational Heat Transfer, May 25–29, 2015, Rutgers University, Piscataway, USA, Danbury: Begell House, 2015, no. CHT-15-289.

Svetushkov, N.N., Iterative method for the numerical solution of a system of integral equations for the heat conduction initial boundary value problem, IOP Conf. Ser.: Mater. Sci. Eng., 2016, vol. 158, art ID 012091. https://doi.org/10.1088/1757-899X/158/1/012091

Svetushkov, N.N., Use of integral strings method for modeling heat loads in the cooling wall of the rocket engine nozzle part, Inf. Tekhnol., 2016, vol. 22, no. 1, pp. 32–36.

Svetushkov, N.N., Computer simulation of technological processes of heat treatment, Tr. Mosk. Aviats. Inst., 2012, no. 58, pp. 1727–6942. http://www.mai.ru/science/trudy/.

Svetushkov, N.N. and Ovsepyan, S.V., Calculation of temperature fields in friction welding of blanks from heat-resistant nickel alloys, Probl. Chern. Metall. Materialoved., 2012, no. 4, pp. 21–25.

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated by Sh. Galyaltdinov

Rights and permissions

About this article

Cite this article

Svetushkov, N.N. Modeling the Structure of a Reinforcing Phase at Heat Treatment of Steel Products. Inorg. Mater. Appl. Res. 10, 12–18 (2019). https://doi.org/10.1134/S2075113319010313

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S2075113319010313