Abstract

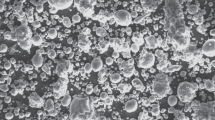

Interaction of the structure of the composite alloy (Al–12 Si)–40 Sn with its mechanical and tribological properties was studied. The alloy was obtained by the liquid-phase sintering of powder briquettes made of the powder mix of tin PO-2 and an atomized aluminum alloy of the eutectic composition Al–12 Si. Sintering was carried out at a temperature below the melting point of the eutectic; otherwise, the sample melted and lost its shape. It was found that the given sintering temperature does not make it possible to obtain samples with high density; their residual porosity was 6–8% and it almost was not decreased with the increase in the sintering time. The obtained material had low mechanical properties, which slightly improved with the increase in the sintering time to two hours. At the same time, the amount of exuded and evaporated tin noticeably increased. Taking into account the undesirable phenomena that occurred during a long exposure of sintered samples at high temperature, the hot densification was carried out after the short-term sintering. Densification of the sintered samples aiming at removal of the residual porosity was carried out in a closed mold under pressure above the ultimate strength of the alloy. It was established that such operation contributed both to significant improvement of strength and ductility of the studied material. In addition, the obtained nonporous material had high wear resistance under dry friction against a steel counterbody; it was especially noticeable during friction under high pressure. The wear rate of samples with a matrix made of the aluminum-silicon alloy was 30% lower as compared with the alloy with the matrix made of pure aluminum at all other conditions being equal.

Similar content being viewed by others

References

Bushe, N.A., Doiskina, V.A., Rakov, K.M., and Gulyaev, A.S., Podshipniki iz alyuminievykh splavov (Bearings from Aluminum Alloys), Moscow: Transport, 1974.

Elleuch, K., Mezlini, S., Fouvry, S., and Kapsa, P., Friction damage of aluminium alloys, Ind. Lubr. Tribol., 2003, vol. 55, no. 6, pp. 279–286.

Bataev, A.A., Bataev, V.A., Kuz’min, N.G., and Ryyankov, K.G., RF Patent 2329321, 2007.

Valizadeh, A.R., Kiani-Rashid, A.R., Avazkonandeh-Gharavol, M.H., and Karimi, E.Z., The influence of cooling rate on the microstructure and microsegregation in Al–30Sn binary alloy, Metallogr. Microstruct. Anal., 2013, vol. 2, pp. 107–112.

Ning, X.-J., Kim, J.-H., Kim, H.-J., and Lee, C., Characteristics and heat treatment of cold-sprayed Al–Sn binary alloy coating, Appl. Surf. Sci., 2009, vol. 225, pp. 3933–3939.

Rusin, N.M., Skorentsev, A.L., and Kolubaev, E.A., Structure and tribotechnical properties of Al–Sn alloys prepared by the method of liquid-phase sintering, Adv. Mater. Res., 2014, vol. 1040, pp. 166–170.

Rusin, N.M. and Skorentsev, A.L., Improving the tribological properties of self-lubricating Al–Sn alloys by their severe plastic processing, Appl. Mech. Mater., 2013, vol. 379, pp. 110–114.

Rusin, N.M., Skorentsev, A.L., and Gurskikh, A.V., Effect of copper additives on mechanical and tribotechnical properties of sintered composites Al–Sn, Key Eng. Mater., 2016, vol. 685, pp. 295–299.

Goudar, D.M., Srivastava, V.C., Rudrakshi, G.B., Raju, K., and Ojha, S.N., Effect of tin on the wear properties of spray formed Al–17Si alloy, Trans. Indian Inst. Met., 2015. doi 10.1007/s12666-015-0573-1

Karavaev, V.E., Skorentsev, A.L., Rusin, N.M., and Korosteleva, E.N., The structure and properties of sintered Al–Si–Sn composites, Trudy mezhdunarodnoi konferentsii s elementami nauchnoi shkoly dlya molodezhi (Proc. Int. Conf. with the Elements of Scientific School for Young Scientists), Tomsk: Tomsk. Politekh. Univ., 2017, pp. 180–181.

Straumal, B., Molodov, D., and Gust, W., Grain boundary wetting phase transitions in the Al–Sn and Al–Sn–Pb systems, Mater. Sci. Forum, 1996, vols. 207–209, pp. 437–440.

Kingery, W.D., Densification during sintering in the presence of a liquid phase, J. Appl. Phys., 1959, vol. 30, no. 3, pp. 301–306.

Rusin, N.M., Skorentsev, A.L., and Mishin, I.P., Evolution of structure and properties of Al–Sn composites under deformation, Inorg. Mater.: Appl. Res., 2015, vol. 6, no. 5, pp. 427–437.

Taylor, G., The mechanism of plastic deformation of crystals. I. Theoretical, Proc. R. Soc. London, Ser. A, 1934, v. 145, no. 3, p. 362–387.

Alieva, S.G., Altman, M.B., Ambartsumian, S.M., et al., Promyshlennye alyuminievye splavy: spravochnik (Industrial Aluminum Alloys: Handbook), Moscow: Metallurgiya, 1984.

Rusin, N.M. and Ivanov, K.V., Plastic flows of Al–40Sn powder alloy during extrusion, Izv. Vyssh. Uchebn. Zaved., Tsvetn. Metall., 2011, no. 6, pp. 48–54.

Author information

Authors and Affiliations

Corresponding author

Additional information

Original Russian Text © N.M. Rusin, A.L. Skorentsev, 2018, published in Perspektivnye Materialy, 2018, No. 5, pp. 66–75.

Rights and permissions

About this article

Cite this article

Rusin, N.M., Skorentsev, A.L. Impact of the Structure on Mechanical and Tribological Properties of Sintered (Al–12 Si)–40 Sn Alloy. Inorg. Mater. Appl. Res. 9, 916–923 (2018). https://doi.org/10.1134/S2075113318050246

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S2075113318050246