Abstract

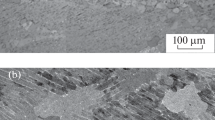

This article discusses test results of corrosion mechanical properties and fatigue properties of deformed semifinished items (forgings and pipes) made of titanium alloys PT-7M and PT-7M with addition of ruthenium. The main mechanical properties of titanium alloys, the structure, and the ruthenium distribution in the structure are determined. Results of static three-point bending tests of specimens with crack are discussed for determination of corrosion mechanical strength and cyclic fatigue strength of forgings and pipes of these alloys in a corrosive medium.

Similar content being viewed by others

References

Gorynin, I.V., Ushkov, S.S., Khatuntsev, A.N., and Loshakova, N.I., Titanovye splavy dlya morskoi tekhniki (Titanium Alloys for Marine Machines), St. Petersburg: Politekhnika, 2007.

Scherbinin, V.F., Leonov, V.P., and Malinkina, Yu.Yu., Increase in corrosion resistance of titanium alloy in concentrated aqueous solutions of chlorides at high temperatures, Inorg. Mater.: Appl. Res., 2013, vol. 4, no. 6, pp. 537–541.

Schutz, R.-W., Stress corrosion resistance of grade 23 and 29 titanium riser pipe in aqueous glycol drill fluids, Proc. 11th World Conf. on Titanium (JIMIC5) “Ti–2007: Science and Technology,” Kyoto: Japan Inst. Met., 2007, vol. 2, pp. 1217–1220.

Report 2–5 Crevice Corrosion Test of Titanium Alloys for Risers and Flowlines. Tests in the Temperature Range 110–150°C, Research Project Titanium Risers and Flowlines, 1997-01-28, Halden: Inst. Energy Technol., 1997.

Tomashov, N.D., Titan i ego korrozionnostoikie splavy na ego osnove (Titanium and Titanium-Based Corrosion-Resistant Alloys), Moscow: Metallurgiya, 1985.

Leonov, V.P., Chudakov, E.V., Kulik, V.P., Malinkina, Yu.Yu., and Tret’yakova, N.V., The influence of corrosion-active medium on the fracture viscosity of titanium pseudo-β alloys, Nov. Materialoved. Nauka Tekh., 2015, no. 6, pp. 9–14.

Malinkina, Yu.Yu., Use of ruthenium for increase of corrosion resistance in hostile environments of industrial titanium alloys, Vopr. Materialoved., 2011, no. 1, pp. 162–166.

Tomashov, N.D. and Al’tovskii, R.M., Korroziya i zashita titana (Corrosion and Protection of Titanium), Moscow: Mashgiz, 1963.

Ruskol, Yu.S., Titanovye konstruktsionnye splavy v khimicheskikh proizvodstvakh. Spravochnik (Titanium Structural Alloys in Chemical Productions. A Handbook), Moscow: Khimiya, 1989.

Il’in, A.A., Kolachev, B.A., and Pol’kin, I.S., Titanovye splavy. Sostav, struktura, svoistva (Titanium Alloys: Composition, Structure, and Properties), Moscow: Vseross. Inst. Legk. Splavov, Mosk. Aviats. Tekhnol. Inst., 2009.

Author information

Authors and Affiliations

Corresponding author

Additional information

Original Russian Text © Yu.Yu. Malinkina, E.V. Chudakov, V.P. Leonov, 2016, published in Voprosy Materialovedeniya, 2016, No. 4(88), pp. 109–119.

Rights and permissions

About this article

Cite this article

Malinkina, Y.Y., Chudakov, E.V. & Leonov, V.P. The influence of ruthenium on structure, corrosion and mechanical properties, and fatigue characteristics of titanium α-alloys in corrosive environment. Inorg. Mater. Appl. Res. 8, 906–913 (2017). https://doi.org/10.1134/S2075113317060090

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S2075113317060090