Abstract

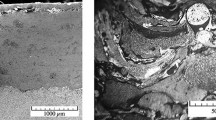

The effect of electromechanical treatment (EMT) on the structure and microhardness of a plasma coating prepared from austenite steel is investigated at 25 and 500°C. The EMT current is varied from 400 to 800 A, the treatment rate is 0.81–3.39 m/min, and the number of passes is from one to four. Consolidation of the coating is observed after EMT. Its microhardness increases from 1866 to 4618 MPa under EMT without heating of the sample and to 5814 MPa under EMT with heating to 500°C.

Similar content being viewed by others

References

Kalita, V.I. and Komlev, D.I., Plazmennye pokrytiya s nanokristallicheskoi i amorfnoi strukturoi (Plasma Coatings with Nanocrystalline and Amorphous Structure), Moscow, Biblioteka, 2008.

Garcia-Alonso, D., Serres, N., Demian, C., Costil, S., Langlade, C., and Coddet, C., Pre-during-post-aser processes to enhance the adhesion and mechanical properties of thermal-sprayed coatings with a reduced environmental impact, J. Therm. Spray Technol., 2001, vol. 20, pp. 719–735.

Karl-Heinz, F. and Agnes, O., Oberflachenfeinwalzen plazmagespritzter Metallschichten, Schweiss und Schneid, 1996, vol. 6, pp. 331–333.

Tillmann, W., Vogli, E., Krebs, B., Tekkaya, A.E., Brosius, A., and Franzen, V., Densification of atmospheric plasma sprayed wear resistant coatings, in Proc. Int. Thermal Spray Conf. May 4–7, 2009, Las Vegas, USA. Eds. B. Marple, M. Hyland. ASM, 2009, pp. 1045–1051.

Pribytkov, G.A., Durakov, V.G., Polev, I.V., and Vagner, M.I., Structure–abrasion wear resistivity relationship of titanium carbide–metal matrix cermets, produced by sintering and by electron-beam facing, Friction Wear, 1999, vol. 20, pp. 393–399.

Kalita, V.I., Bagmutov, V.P., Zaharov, I.N., Komlev, D.I., and Ivannikov, A.Yu., Strengthening of plasma coatings by electromechanical treatment, Fiz. Khim. Obrab. Mater., 2008, no. 1, pp. 38–42.

Komlev, D.I., Kalita, V.I., Radyuk, A.A., Menshikov, G.A., Vlasenko, A.N., and Ivannikov, A.Yu., Effect of the contact seam welding on plasma coatings, Fiz. Khim. Obrab. Mater. 2013, No. 4, pp. 69–77.

Bagmutov, V.P., Kalita, V.I., Zaharov, I.N., Ivannikov, A.Yu., and Zaharova, E.B., Structure and microhardness of plasma coatings hardened by nanoparticles after electromechanical treatment. Steel in Translation, 2009, vol. 39, pp. 870–877.

Komlev, D.I., Kalita, V.I., Menshikov, G.A., Vlasenko, A.N., Radyuk, A.A., and Ivannikov, A.Yu., The effect of resistance spot welding on plasma sprayed coatings, Inorg. Mater.: Appl. Res., 2013, vol. 4, pp. 236–246.

Isakaev, M.-E.Kh., Ilichyov, M.V., Ochkan, A.L., and Filippov, G.A., Effective method for prolongation of the life time of railway frogs by plasma facing, Technol. Metal., 2003, no. 7, pp. 29–34.

Becker, M. and Klemm, H., Handbuch der metallographischen Atzverfahren. A comprehensive collection of etching recipes, VEB Deutscher Verlag fur Grundstoffindustrie, Leipzig, 1966.

Bagmutov, V.P., Zakharov, I.N., Ivannikov, A.Yu., and Poplavsky, E.V., Thermal process simulation at electromechanical hardening of plasma coverings, Vestn. Voronezh. Gos. Tekhn. Univ., 2007, vol. 3, no. 8, pp. 135–140.

Dudkina, N.G., Zakharov, I.N., Ermolov, V.S., and Ivannikov, A.Yu., Dependence of microhardness of a regular discrete structures of the surface layer of a mild steel on the conditions of electromechanical treatment, Probl. Mashinostr. Nadezhn. Mashin, 2006, no. 5, pp. 62–68.

Pustov, Yu.A., Zolotarev, A.S., Gladkikh, N.A., Kalita, V.I., Komlev, D.I., Radyuk, A.A., and Ivannikov, A.Yu., Structure and corrosion–electrochemical behavior of systems “amorphous plasma coating based on iron— steel substrate”, Fiz. Khim. Obrab. Mater., 2015, no. 3, pp. 35–43.

DIN 50150-1976. Testing of Steel and Cast Steel; Conversion Table for Vickers Hardness, Brinell Hardness, Rockwell Hardness and Tensile Strength, 1976.

Otsubo, F., Era, H., Uchida, T., and Kishitake, K., Properties of Cr3C2–NiCr cermet coating sprayed by high power plasma and high velocity oxy–fuel processes, J. Thermal Spray Technol., 2000, vol. 9, pp. 499–504.

Author information

Authors and Affiliations

Corresponding authors

Additional information

Original Russian Text © A.Yu. Ivannikov, V.I. Kalita, D.I. Komlev, A.A. Radyuk, V.P. Bagmutov, I.N. Zakharov, S.N. Parshev, 2015, published in Fizika i Khimiya Obrabotki Materialov, 2015, No. 5, pp. 44–53.

Rights and permissions

About this article

Cite this article

Ivannikov, A.Y., Kalita, V.I., Komlev, D.I. et al. Effect of electromechanical treatment on the structure and microhardness of plasma coating from Cr–Mn steel. Inorg. Mater. Appl. Res. 7, 363–371 (2016). https://doi.org/10.1134/S2075113316030096

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S2075113316030096