Abstract

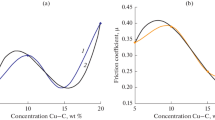

Results of the wear tests of composite antifriction coatings based on aluminum alloy reinforced with micron sized ceramic particles in comparison with coatings based on babbit containing carbon nanotubes (CNTs) are discussed. It is shown that the introduction of the reinforcing particles in the form of the silicon carbide or CNTs into the matrix alloys based on aluminum and babbit stabilizes the dry sliding friction process and promotes improvement of the tribological characteristics.

Similar content being viewed by others

References

Xenevich, I.P., Science in tribology and problems of applied mechanics terrestrial mobile machines, Privodnaya Tekhnika, 2003, no. 5, pp. 2–5.

Suresh, S. and Mortensen, A., Fundamentals of Functionally Graded Materials: Processing and Thermomechanical Behavior of Graded Materials and MetalCeramic Composites, London: IOM Communications, 1998.

Mikheev, R.S. and Chernyshova, T.A., Alumomatrichnye kompozitsionnye materialy s karbidnym uprochneniem dlya resheniya zadach novoy tekhniki (AluminumMatrix Composite Materials with Carbide Hardening for the Solution of Problems of New Euipment), Moscow: Mask, 2013.

Chernyshova, T.A., Panfilov, A.V., and Panfilov, A.A., Application of aluminum-matrix composite materials in friction units of industrial and transport equipment, Zagotovit. Proizvod. Mashinostr., 2006, no. 5, pp. 38–43.

Chernyshova, T.A., Mikheev, R.S., Kalashnikov, I.E., and Kharlamov, E.I., Development and testing of Al–SiC and Al–TiC composite materials for application in friction units of oil-production equipment, Inorg. Mater.: Appl. Res., 2011, vol. 2, pp. 322–329.

Dasgupta, R., Aluminum alloy-based metal matrix composites: A potential material for wear resistant application, Int. Scholar. Res. Network (ISRN) Metallur., 2012, Art. ID 594573, pp. 1–14.

Mikheev, P.C., Chernyshova, T.A., and Kobeleva, L.I., Tribotechnical properties of disperse filled Al–TiC composite materials, Materialovedeniye, 2011, no. 1, pp. 14–22.

Miyamoto, Y., Functionally Graded Materials: Design, Processing and Applications, Boston, MA: Kluwer Academic, 1999.

Kevorkijan, V., Functionally graded aluminum-matrix composites, Am. Ceram. Soc. Bull., 2003, vol. 82, no. 2, pp. 33–37.

Kobernik, N.V., Chernyshov, G.G., Gvozdev, P.P., Chernyshova, T.A., Kobeleva, L.I., and Vaganov, V.E., Antifrictional properties of the coverings received by a plasma babbit welding with carbon nanotubes, Svarka Diagnostika, 2013, no. 3, pp. 27–31.

Kobernik, N.V., Chernyshov, G.G., Mikheev, R.S., Chernyshova, T.A., and Kobeleva, L.I., Arc welding of wearproof composite coverings, Fiz. Khim. Obrab. Mater., 2009, no. 1, pp. 51–55.

Mikheev, R.S., Kobernik, N.V., Chernyshov, G.G., Chernyshova, T.A., Panfilov, A.V., Panfilov, A.A., Panfilov, A.A., and Petrunin, A.V., Prutki iz alumomatrichnogo kompozitsionnogo materiala dlya naplavki iznosostoikikh kompozitsionnykh pokrytii (Bars from aluminum-matrix composite material for surfacing of wear resistant composite coating). Patent No., 2361710, Rus. Feder., MPK B23 K35/28, Bull. No. 20.

Mikheev, R.S., Kobernik, N.V., and Chernyshov, G.G., Influence of filler composite materials composition on weld pool fluidity, Svarka Diagnostika, 2012, no. 6, pp. 11–15.

Shipway, P.H., Kennedy, A.R., and Wilkes, A.J., Sliding wear behavior of aluminum-based metal matrix composites produced by a novel liquid route, Wear, 1998, vol. 216, pp. 160–171.

Chichinadze, A.V., Berliner, E.M., and Brown, E.D., Trenie, iznos, smazka (tribologiya i tribotekhnika) (Friction, Wear and Greasing (Tribology and Tribotechnics), Moscow: Mashinostroenie, 2003.

Penkin, N.S., Penkin, A.N., and Serbin, V.M., Osnovy tribologii i tribotekhniki (Fundamentals of Tribology and Tribotechnics), Moscow: Mashinostroenie, 2008.

Biswas, S.K., Some mechanisms of tribofilm formation in metal/metal and ceramic/metal sliding interaction, Wear, 2000, vol. 245, pp. 178–189.

Sato, H., Murase, T., Fujii, T., Onaka, S., Watanabe, Y., and Kato, M., Formation of wear-induced layer with nanocrystalline structure in Al–Al3Ti functionally graded material, Acta Mater., 2008, vol. 56, pp. 4549–4558.

Author information

Authors and Affiliations

Corresponding author

Additional information

Original Russian Text © R.S. Mikheev, N.V. Kobernik, I.E. Kalashnikov, L.K. Bolotova, L.I. Kobeleva, 2015, published in Perspektivnye Materialy, 2015, No. 3, pp. 48–54.

Rights and permissions

About this article

Cite this article

Mikheev, R.S., Kobernik, N.V., Kalashnikov, I.E. et al. Tribotechnical properties of antifriction coatings based on composite materials. Inorg. Mater. Appl. Res. 6, 493–497 (2015). https://doi.org/10.1134/S2075113315050111

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S2075113315050111