Abstract

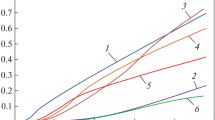

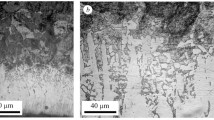

Erosion of the surface of St3-type steel and BrB2-type bronze samples as well as bronze and copper samples with zirconium coating under the effect of compression plasma flows is studied. The results show the increase in mass removed from the surface of samples with the growth of energy absorbed by the surface layer and with the growth of the number of pulses. Probable mechanisms of erosion have been discussed. Erosion leads to the decrease in the coating element concentration in the alloyed layer in the case of the coating/substrate system treatment. This effect depends on thermal characteristics of the treated material.

Similar content being viewed by others

References

Mirkin, L.I., Fizicheskiye osnovy obrabotki materialov luchami lazera (Physical Foundations of Material Treatment by Laser Beams), Moscow: Mos. Gos. Univ., 1975.

Anisimov, S.I. and Lukyanchuk, B.S., Selected problems of laser ablation theory, Phys.-Usp., 2002, vol. 45, pp. 293–324.

Tereshin, V.I., Garkusha, I.E., Bandura, A.N., Byrka, O.V., Chebotarev, V.V., Makhlaj, V.A., Solyakov, D.G., and Wuerz, H., Influence of plasma pressure gradient on melt layer macroscopic erosion of metal targets in disruption simulation experiments, J. Nucl. Mater., 2003, vol. 313–316, pp. 685–689.

Bulgakov, L.V., Bulgakova, N.M., Burakov, I.M., et al., Sintez nanorazmernykh materialov pri vozdeistvii moshchnykh potokov energii na veshchestvo (Synthesis of Nanosized Materials under Effect of Powerful Energy Flows on Substance), Novosibirsk: Inst. Heat-Physics of Sibir. Branch Russ. Acad. Sci., 2009.

Boiko, V.I., Valyaev, A.N., and Pogrebnyak, A.D., Metal modification by high-power pulsed particle beams, Phys.-Usp., 1999, vol. 42, pp. 1139–1166.

Ryabchikov, A.I., Petrov, A.V., Struts, V.K., Mytnikov, A.V., Usov, Yu.P., and Renk, T.J., Structural-phase composition and tribological characteristics of fullerenes containing carbonic coatings obtained using high-power ion beams, Surf. Coat. Technol., 2009, vol. 203, pp. 2608–2611.

Makarov, G.N., Laser applications in nanotechnology: Nanofabrication using laser ablation and laser nanolithography, Phys.-Usp., 2013, vol. 56, pp. 643–682.

Gribkov, V.A., Grigoryev, F.I., Kalin, B.A., and Yakushin, V.L., Perspektivnye radiatsionno-puchkovye tekhnologii obrabotki materialov (Advanced Radiation-Beams Technologies of Materials Treatment), Moscow: Krugly God, 2001.

Linke, J., Barabash, V.R., Bolt, H., Gervash, A., Mazul, I., Ovchinnikov, I., and Rödig, M., Erosion of metals and carbon based materials during disruptions — simulation experiments in plasma accelerators, J. Nucl. Mater., 1994, nos. 212–215, pp. 1195–1200.

Astashynski, V.M., Ananin, S.I., Askerko, V.V., Kostyukevich, E.A., Kuzmitski, A.M., Uglov, V.V., Cherenda, N.N., Anishchik, V.M., Sveshnikov, Yu.V., Astashynski, V.V., Kvasov, N.T., Danilyuk, A.L., Punko, A.V., and Pauleau, Y., Deposition of nanostructured metal coatings on modified silicon surfaces in magnetoplasma compressor, Vacuum, 2005, vol. 78, pp. 157–160.

Uglov, V.V., Anishchik, V.M., Cherenda, N.N., Sveshnikov, Yu.V., Astashynski, V.M., Kostyukevich, E.A., Kuzmitski, A.M., and Askerko, V.V., The formation of a tungsten containing surface layer in a carbon steel by compression plasma flow, Surf. Coat. Technol., 2008, vol. 202, pp. 2439–2442.

Uglov, V.V., Cherenda, N.N., Anishchik, V.M., Stalmashonak, A.K., Astashinski, V.M., and Mishchuk, A.A., et al., Formation of alloying layers in a carbon steel by compression plasma flows, Vacuum, 2007, vol. 81, pp. 1341–1344.

Kalin, B.A., Skorov, D.M., and Yakushin, V.L., Problemy vybora materialov dlya termoyadernykh reaktorov: radiatsionnaya eroziya (Selection of Materials for Fusion Reactors: Radiation Erosion), Moscow: Energoatomizdat, 1985.

Grigoryev, I.S. and Meylikhov, Ye.Z., Fizicheskiye velichiny: spravochnik (Physical Quantities: Handbook), Moscow: Energoatomizdat, 1991.

Laskovnev, A.P., Cherenda, N.N., Basalay, A.V., Uglov, V.V., Anishchik, V.M., Astashinsky, V.M., and Kuzmitsky, A.M., Modification of copper surface by compression plasma flows, Probl. Phys., Mathem. Tech., 2013, no. 3, pp. 24–29.

Pliskovsky, V.Ya., Konstruktsionnye materialy i element vakuumnykh system (Structural Materials and Details of Vacuum Systems), Moscow: Mashinostroyeniye, 1976.

Astashinsky, V.M., Leyvi, A.Ya., Talala, K.A., Yalovets, A.P., Uglov, V.V., and Cherenda, N.N., Change in the relief of a target surface treated by compression plasma flows, J. Surf. Invest. X-ray, Synchr. Neutron Techn., 2013, vol. 7, pp. 1005–1012.

Astashynski, V.M., Investigation of plasma parameters during the action of compression plasma flows on surfaces, Proc. 4th Int. Conf. on Plasma Physics and Plasma Technology Minsk: Institute of Molec. At. Phys. Nat. Acad. Sci. Belarus, 2003, vol. 2.

Maltsev, I.V. and Mirzoyev, A.A., Liquid iron viscosity: Molecular-dynamics simulation with an embeddedatom potential, Vestn. Yuzhn.-Ural. Gos. Univ.: Matem., Mekh., Fiz., 2009, no. 22, pp. 79–83.

Assael, M.J., Kalyva, A.E., Antoniadis, K.D., Banish, R.M., Egry, I., Wu, J., Kaschnitz, E., and Wakeham, W.A., Reference data for the density and viscosity of liquid copper and liquid tin, J. Phys. Chem. Ref. Data, 2010, vol. 39, p. 033105. http://dx.doi.org/10.1063/1.3467496

Author information

Authors and Affiliations

Corresponding author

Additional information

Original Russian Text © N.N. Cherenda, A.P. Laskovnev, A.V. Basalai, V.V. Uglov, V.M. Astashynski, A.M. Kuzmitski, 2014, published in Perspektivnye Materialy, 2014, No. 11, pp. 5–14.

Rights and permissions

About this article

Cite this article

Cherenda, N.N., Laskovnev, A.P., Basalai, A.V. et al. Erosion of materials under the effect of compression plasma flows. Inorg. Mater. Appl. Res. 6, 114–120 (2015). https://doi.org/10.1134/S2075113315020070

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S2075113315020070