Abstract

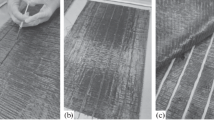

The characteristics of a polymer-composition material consisting of carbon-fabric and two types of matrices—more specifically, epoxy and organosilicon—have been considered. The main roles of the organosilicon matrix are to relax stresses arising in the parts from carbon-fiber-reinforced plastic at loads and inhibit (or stop) crack propagation. Using a tomograph, the structure of composition material was determined, a finite-element model was developed, and the stress–strain state was calculated depending on elastic characteristics of the matrices. The load factor values were calculated. It was determined that introduction of organosilicon material to the composite could decrease the stress values at the crack top, which significantly increases the service life of these materials.

Similar content being viewed by others

REFERENCES

A. A. Berlin, “Fatigue strength of natural materials,” Polym. Sci., Ser. D 13, 57 (2020).

E. A. Kosenko, N. I. Baurova, and V. A. Zorin, Nature-Like Materials and Constructions in Machine Engineering: Monograph (Moscow Automobile and Road Construction State Technical Univ., Moscow, 2020) [in Russian].

E. A. Kosenko, N. I. Baurova, and V. A. Zorin, “Service properties of composites with various types of hybrid matrices,” Russ. Metall. (Engl. Transl.) 2020, 1526–1530 (2020).

E. A. Kosenko, N. I. Baurova, and V. A. Zorin, “The development of natural-like polymer composite materials with liquid matrix and their use in mechanical engineering,” Polym. Sci., Ser. D 13, 341–344 (2020).

A. I. Rudskoi and N. I. Baurova, “Technological heredity during the production and operation of structural materials,” Russ. Metall. (Engl. Transl.) 2019, 1378–1383 (2019).

N. I. Baurova, “Influence of nanostructured defects in carbon fibers and ribbons on sensor properties,” Polym. Sci., Ser. D 4, 242–245 (2011).

V. A. Nelyub and A. A. Berlin, “A study of the chemical structure of the surface of carbon fibers before and after oxide,” Polym. Sci., Ser. D 8, 175–180 (2015).

G. V. Malysheva and Y. Y. Shimina, “Influence of preparation technology on carbon-fiber-composite component composition,” Fibre Chem. 46 (4), 237–240 (2014).

P. P. Maung, T. L. Htet, and G. V. Malysheva, “Simulation and optimization of vacuum assisted resin infusion process for large-sized structures made of carbon fiber-reinforced plastic,” IOP Conf. Ser.: Mater. Sci. Eng. 709 (2), 022041 (2020).

P. P. Maung, G. V. Malysheva, and S. A. Gusev, “A study of the effect of network angle of fabrics on kinetics of impregnation upon molding of articles made from carbon plastics,” Polym. Sci., Ser. D 9, 407–410 (2016).

N. I. Baurova and A. Y. Sergeev, “Application of differential-scanning calorimetry for studying the properties of filled adhesive materials,” Polym. Sci., Ser. D 7, 140–144 (2014).

A. Y. Sergeyev, R. A. Turusov, N. I. Baurova, and A. M. Kuperman, “Stresses arising during cure of the composite wound on the cylindrical surface of an element of exhaust system,” Mech. Compos. Mater. 51 (3), 321–332 (2015).

A. Y. Sergeev, R. A. Turusov, and N. I. Baurova, “Strength of the joint of an anisotropic composite and a cylindrical element of the exhaust system of road vehicles,” Mech. Compos. Mater. 52 (1), 89–98 (2016).

V. A. Nelyub, A. S. Borodulin, L. P. Kobets, and G. V. Malysheva, “Thixotropy hysteresis and structure formation in elastomeric suspensions,” Inorg. Mater.: Appl. Res. 9, 603–608 (2018).

C. Yangyang and G. Malysheva, “Method for determining the rational regimes of curing determining the rational regimes of curing products from polymer composite materials,” Mater. Today: Proc. 11, 128–133 (2019).

N. I. Baurova, “Durability models of adhesive material using catastrophe theory,” Polym. Sci., Ser. D 2, 130–132 (2009).

V. A. Zorin, N. I. Baurova, and A. M. Shakurova, “Investigation of the structure of an encapsulated anaerobic adhesive,” Polym. Sci., Ser. D 7, 303–305 (2014).

L. P. Kobets, A. S. Borodulin, and G. V. Malysheva, “Study of microcapillary impregnation of carbon fiber by epoxy binder,” Fibre Chem. 48 (4), 311–315 (2016).

A. P. Petrova and G. V. Malysheva, Adhesives, Adhesive Binders, and Adhesive Prepregs: Manual, Ed. by E. N. Kablov (All-Russian Institute of Aviation Materials, Moscow, 2017) [in Russian].

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

The authors declare that they have no conflicts of interest.

Additional information

Translated by A. Muravev

Rights and permissions

About this article

Cite this article

Kosenko, E.A., Nelyub, V.A. Evaluation of the Stress–Strain State of a Polymer Composition Material with a Hybrid Matrix. Polym. Sci. Ser. D 15, 240–244 (2022). https://doi.org/10.1134/S1995421222020137

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S1995421222020137