Abstract

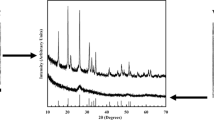

New opportunity to synthesize nano- and ultradispersed powdered materials by combining of two procedures, classical liquid-phase precipitation and low-temperature microwave calcination, at a rather simple instrumentation is described. It was found in precipitation of precursors that, depending on the synthesis conditions (solution pH, amount of carbon, synthesis on the vessel surface or in the solution bulk), particles of hydrated vanadium oxide have different morphologies. It was also found that precursor powders have an insignificant microporosity, which is preserved in the final products in trace amounts upon thermal treatment of samples. Intermediate and final vanadium products were synthesized in an electromagnetic field in a flow of argon, their phase composition and structure were examined in the stages of thermolysis, reduction, and carbidization, and their lattice constants were calculated. The morphology, size, and particle size distribution in the samples under study were determined.

Similar content being viewed by others

References

Shi, X.L., Shao, G.Q., Duan, X.L., et al., Mater. Charact., 2006, vol. 57, nos. 4–5, pp. 358–370.

Weidow, J., Norgren, S., and Andren, H.O., Int. J. Refract. Met. Hard Mater., 2009, vol. 27, no. 5, pp. 817–822.

Spriggs, G.E., Int. J. Refract. Met. Hard Mater., 1995, vol. 13, no. 5, pp. 241–255.

Bock, A., Schubert, W.D., and Lux, B., Powder Metall. Int., 1992, vol. 24, no. 1, pp. 20–26.

McCandlish, L.E., Kear, B.H., and Kim, B.K., Mater. Sci. Technol., 1991, vol. 6, no. 10, pp. 953–957.

Hashe, N.G., Neethling, J.H., and Andren, H.O., Int. J. Refract. Met. Hard Mater., 2007, vol. 25, no. 3, pp. 207–213.

Nikolaenko, I.V., Kedin, N.A., Shveikin, G.P., et al., Int. J. Mater. Res., 2014, vol. 105, no. 3, pp. 314–317.

Nikolaenko, I.V., Kedin, N.A., and Shveikin, G.P., Int. J. Mater. Res., 2014, vol. 105, no. 12, pp. 1232–1235.

Author information

Authors and Affiliations

Corresponding author

Additional information

Original Russian Text © I.V. Nikolaenko, A.E.Krasovskaya, G.P. Shveikin, 2015, published in Zhurnal Prikladnoi Khimii, 2015, Vol. 88, No. 1, pp. 40–44.

Rights and permissions

About this article

Cite this article

Nikolaenko, I.V., Krasovskaya, A.E. & Shveikin, G.P. Combined method for obtaining ultradispersed powders of vanadium oxides and carbide. Russ J Appl Chem 88, 35–39 (2015). https://doi.org/10.1134/S1070427215010061

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S1070427215010061