Abstract

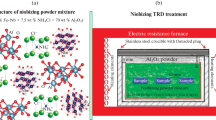

AISI D2 cold-work tool steel is usually used for the purpose of hardness and wear resistance. Thermoreactive diffusion coating (TRD) treatment can be applied to this type of tool steel to improve the surface hardness. Since the rollers made of D2 tool steels are susceptible to wear fatigue, its surface hardness is of critical importance. A vanadium carbide coating was applied to the D2 tool steel samples by immersion in a borax liquid bath containing ferrovanadium, aluminum, and boric acid. Coating process and hardening heat treatment were carried out simultaneously in two steps. Firstly the samples were preheated up to 500°C and then TRD coating was performed on the samples at various temperatures for different times. Secondly the samples were undergone a mar-tempering heat treatment cycle in which the samples were austenitized in a BaCl2 molten bath at 1070°C for 30 minutes, oil quenched and then a two stage tempering treatment was applied to the quenched samples. The surface hardness of the coated sample was evaluated as 2300–3200 HV at various conditions while the hardness of the bulk was measured as 670–720 HV. XRD analysis of the coating showed that the main component was vanadium carbide (V8C7). Finally the kinetic study of coating was carried out based on determined rate curves, which showed that the diffusion of carbon atoms in the coating layer controlled the coating process.

Similar content being viewed by others

References

Atık, Enver, Yunker Umut, and Merıc Cevdet, Tribology International, 2003, pp. 155–161.

Keown, S., Hist. Mctall., 1985, vol. 19, no.1, pp. 97–103.

Oliverira, C.K.N., Riofano, R.M.M., and Casteletti, L.C., Mater. Let., 2005, vol. 59, pp. 1719–1722.

Oliverira, C.K.N., Benassi, C.L., and Casteletti, L.C., Surface & Coatings Technology, 2006, vol. 201, pp. 1880–1885.

Chen, Y. and Chen, F., Materials Chemistry & Physics, 2005, vol. 91, pp. 192–199.

Chen, F., Lee, P.Y., and Yeh, M., Materials Chemistry & Physics, 1998, vol. 53, pp. 19–27.

Plumb, S., Metallurgia, 1085, vol. 52, p. 59.

ASM Metals Handbook, “Heat Treatment,” 1998, vol. 4.

Child, H.C., Plumb, S.A., and McDermott, J.J., Int. Conf. on Heat Treatment Proceedings, London, UK, May 1984, The Metals Society, 1984, p. 5.1.

Sen Saduman, Sen Ugur, and Bindal Cuma, Surface & Coatings Technology, 2005, vol. 191, pp. 274–285.

Aghaie-Khafri, M. and Fazlalipour, F., J. Phys. & Chem. Solids, 2008, vol. 69, pp. 2465–2470.

Arai, T. and Moriyama, S., Thin Solid Films, 1994, vol. 249, pp. 54–61

Arai, T. and Moriyama, S., Thin Solid Films, 1995, vol. 259, pp. 174–180.

Arai, T., Thin Solid Films, 1993, vol. 229, pp. 171–179.

Sen, S., Vacuum, 2005, vol. 79, pp. 63–70.

Sen, U., Materials Chemistry & Physics, 2004, vol. 86, pp. 189–194.

Author information

Authors and Affiliations

Corresponding author

Additional information

The text was submitted by the authors in English.

Rights and permissions

About this article

Cite this article

Shirinbayan, M., Shafyei, A. & Aboutalebi, M.R. Kinetics of vanadium carbide coating produced on AISI D2 steel by thermoreactive diffusion technique. Russ J Appl Chem 87, 1930–1935 (2014). https://doi.org/10.1134/S1070427214120222

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S1070427214120222