Abstract

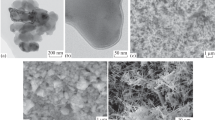

The effect of an additive of 0.5 wt % of zirconium oxide on the kinetics of electropulse plasma sintering (EPS) of submicron and micron α-Al2O3 powders. Al2O3–0.5% ZrO2 compositions were obtained by mixing Al2O3 powders in a planetary mill with grinding media from stabilized zirconium oxide. The activation energy of EPS was estimated using the Yang–Cutler model. It is shown that the density and average grain size in ceramics sintered from submicron Al2O3 powders are significantly affected by the nonequilibrium state of the interfaces formed as a result of the transformation of the amorphous phase present on the particle surface during EPS. The grain size and density of ceramics Al2O3–0.5% ZrO2, sintered from micron powders are significantly affected by the coalescence of ZrO2 particles.

Similar content being viewed by others

REFERENCES

A. G. Evans and T. G. Langdon, Structural Ceramics (Pergamon, Oxford, 1976).

V. Ya. Shevchenko and S. M. Barinov, Technical Ceramics (Nauka, Moscow, 1993) [in Russian].

A. Z. A. Azhar, M. M. Ratman, and Z. A. Ahmad, J. Alloys Compd. 478 (1–2), 608 (2009). https://doi.org/10.1016/j.jallcom.2008.11.156

J. Chai, Y. Zhu, T. Shen, Y. Liu, L. Niu, S. Li, P. Jin, M. Cui, and Z. Wang, Ceram. Int. 46 (17), 27143 (2020). https://doi.org/10.1016/j.ceramint.2020.07.194

A. Ruys, Alumina Ceramics Biomedical and Clinical Applications (Woodhead, Cambridge, 2019).

A. P. Garshin, V. M. Gropyanov, G. P. Zaitsev, and S. S. Semenov, Ceramics for Machine Engineering (Nauchtekhlitizdat, Moscow, 2003) [in Russian].

S. Meir, S. Kalabukhov, and S. Hayun, Ceram. Int. 40 (8), 1287 (2014). https://doi.org/10.1016/j.ceramint.2014.04.059

D. Jiang, D. M. Hulbert, J. D. Kuntz, U. Anselmi-Tamburini, and A. K. Mukherjee, Mater. Sci. Eng., A 463 (1–2), 89 (2007). https://doi.org/10.1016/j.msea.2006.07.163

M. Tokita, Ceramics 4 (2), 160 (2021). https://doi.org/10.3390/ceramics4020014

Z.-Y. Hu, Z.-H. Zhang, X.-W. Cheng, F.-C. Wang, Y.-F. Zhang, and S.-L. Li, Mater. Des. 191, 108662 (2020). https://doi.org/10.1016/j.matdes.2020.108662

D. J. Green, J. Am. Ceram. Soc. 65 (12), 610 (1982). https://doi.org/10.1111/j.1151-2916.1982.tb09939.x

F. F. Lange and M. M. Hirlinger, J. Am. Ceram. Soc. 67 (3), 164 (1984). https://doi.org/10.1111/j.1151-2916.1984.tb19734.x

M. S. Boldin, A. A. Popov, E. A. Lantsev, A. V. Nokhrin, and V. N. Chuvil’deev, Materials 15 (6), 2167 (2022). https://doi.org/10.3390/ma15062167

F. A. T. Guimarães, K. L. Silva, V. Trombini, J. J. Pierri, J. A. Rodrigues, R. Tomasi, and E. M. J. A. Pallone, Ceram. Int. 35 (2), 741 (2009). https://doi.org/10.1016/j.ceramint.2008.02.002

V. N. Chuvil’deev, M. S. Boldin, Ya. G. Dyatlova, V. I. Rumyantsev, and S. S. Ordan’yan, Russ. J. Inorg. Chem. 60 (8), 987 (2015). https://doi.org/10.1134/S0036023615080057

M. N. Rahaman, Ceramic Processing and Sintering (Marcel Dekker, New York, 2003).

E. A. Olevsky and L. Froyen, J. Am. Ceram. Soc. 92 (s1), S122 (2009). https://doi.org/10.1111/j.1551-2916.2008.02705.x

W. S. Young and I. B. Culter, J. Am. Ceram. Soc. 53 (12), 659 (1970). https://doi.org/10.1111/j.1151-2916.1970.tb12036.x

E. A. Lantsev, N. V. Malekhonova, Yu. V. Tsvetkov, Yu. V. Blagoveshchensky, V. N. Chuvil’deev, A. V. Nokhrin, M. S. Boldin, P. V. Andreev, K. E. Smetanina, and N. V. Isaeva, Inorg. Mater.: Appl. Res. 12 (3), 650 (2021). https://doi.org/10.1134/S2075113321030242

H. J. Frost and M. F. Ashby, Deformation Mechanism Maps: The Plasticity and Creep of Metals and Ceramics (Pergamon, Oxford, 1982).

A. E. Paladino and R. L. Coble, J. Am. Ceram. Soc. 46 (3), 133 (1963). https://doi.org/10.1111/j.1151-2916.1963.tb11696.x

V. N. Chuvil’deev and E. S. Smirnova, Phys. Solid State 58 (7), 1487 (2016). https://doi.org/10.1134/S1063783416070118

V. I. Betekhtin, A. G. Kadomtsev, A. Yu. Kipyatkova, and A. M. Glezer, Phys. Solid State 40 (1), 74 (1998). https://doi.org/10.1134/1.1130237

V. N. Chuvil’deev, Nonequilibrium Grains Boundaries in Metals. Theory and Applications (Fizmatlit, Moscow, 2004) [in Russian].

J. Wang and R. Raj, J. Am. Ceram. Soc. 74 (8), 1959 (1991). https://doi.org/10.1111/j.1151-2916.1991.tb07815.x

T.-S. Yeh and M. D. Sacks, J. Am. Ceram. Soc. 71 (12), C-484 (1988). https://doi.org/10.1111/j.1151-2916.1988.tb05812.x

ACKNOWLEDGMENTS

The study by transmission electron microscopy was performed on the equipment of the Core Facility Center “Materials Science and Metallurgy” of National University of Science and Technology “MISiS”, project no. 075-15-2021-696 of the Ministry of Education and Science of Russia.

Funding

This work was supported by the Russian Science Foundation, grant no. 20-73-10113.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

The authors declare that they have no conflicts of interest.

Additional information

Translated by M. Drozdova

Rights and permissions

About this article

Cite this article

Boldin, M.S., Popov, A.A., Murashov, A.A. et al. Investigation of the Effect of a Small Addition of ZrO2 on the Density and Growth of Grains of Fine-Grained Aluminum Oxide. Tech. Phys. 67, 570–580 (2022). https://doi.org/10.1134/S1063784222080035

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S1063784222080035