Abstract

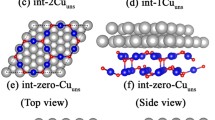

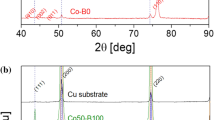

In a series of NiFe/Cu/IrMn structures with a variable effective thickness of the nonmagnetic copper interlayer (up to its absence in the NiFe/IrMn sample), we observed a decrease in the exchange bias and coercive force with an increase in the effective thickness of the copper layer. The coalescence of copper islands when the effective thickness of the copper layer reaches 1 nm changes the contact exchange interaction between the ferromagnet and antiferromagnet in NiFe–IrMn to indirect exchange interaction through the conduction electrons of the copper layer in NiFe–Cu–IrMn. The structural quality of single-crystal ferromagnetic and antiferromagnetic layers does not change, and the magnetization reversal occurs without the participation of domains in the temperature range of 2–300 K. Simulation of the deposition dynamics demonstrates the island structure of the film at the initial stages up to an effective thickness of 1 nm.

Similar content being viewed by others

REFERENCES

V. Baltz, A. Manchon, M. Tsoi, T. Moriyama, T. Ono, and Y. Tserkovnyak, Rev. Mod. Phys. 90, 015005 (2018).

J. Y. Son, C. H. Kim, J. H. Cho, Y. H. Shin, and H. M. Jang, ACS Nano 4, 3288 (2010).

R. Stamps, J. Phys. D 33, R247 (2000).

P. Manna and S. Yusuf, Phys. Rep. 535, 61 (2014).

J. McCord, R. Mattheis, and D. Elefant, Phys. Rev. B 70, 094420 (2004).

Y. T. Chen, Nanoscale Res. Lett. 4, 90 (2008).

Y. Hu, X. Li, X. Chi, A. Du, and F. Shi, J. Phys. D 51, 055001 (2018).

T. R. Gao, Z. Shi, S. M. Zhou, R. Chantrell, P. Asselin, X. J. Bai, J. Du, and Z. Z. Zhang, J. Appl. Phys. 105, 053913 (2009).

N. P. Aley, G. Vallejo-Fernandez, R. Kroeger, B. Lafferty, J. Agnew, Y. Lu, and K. O. Grady, IEEE Trans. Magn. 44, 2820 (2008).

H. S. Jung, O. Traistaru, and H. Fujiwara, J. Appl. Phys. 95, 6849 (2004).

H. Sang, Y. W. Du, and C. L. Chien, J. Appl. Phys. 85, 4931 (1999).

J. P. King, J. N. Chapman, M. F. Gillies, and J. C. S. Kools, J. Phys. D 34, 528 (2001).

T. Q. Hung, S. Oh, B. Sinha, J. R. Jeong, D. Y. Kim, and C. G. Kim, J. Appl. Phys. 107, 09E715 (2010).

L. Thomas, A. J. Kellock, and S. S. P. Parkin, J. Appl. Phys. 87, 5061 (2000).

S. Nicolodi, L. C. C. M. Nagamine, A. D. C. Viegas, J. E. Schmidt, L. G. Pereira, C. Deranlot, F. Petroff, and J. Geshev, J. Magn. Magn. Mater. 316, e97 (2007).

J. Sort, F. Garcia, B. Rodmacq, S. Auffret, and B. Dieny, J. Magn. Magn. Mater. 272–276, 355 (2004).

K. Li, Z. Guo, G. Han, J. Qiu, and Y. Wu, J. Appl. Phys. 93, 6614 (2003).

F. Spizzo, M. Tamisari, F. Chinni, E. Bonfiglioli, and L. Del Bianco, J. Magn. Magn. Mater. 421, 234 (2017).

Y. T. Chen, Y. C. Lin, S. U. Jen, J. Y. Tseng, and Y. D. Yao, J. Alloys Compd. 509, 5587 (2011).

A. Elzwawy, A. Talantsev, and C. Kim, J. Magn. Magn. Mater. 458, 292 (2018).

I. L. Castro, V. P. Nascimento, E. C. Passamani, A. Y. Takeuchi, C. Larica, M. Tafur, and F. Pelegrini, J. Appl. Phys. 113, 203903 (2013).

R. B. Morgunov, A. D. Talantsev, M. V. Bakhmet’ev, and N. V. Granovskii, Phys. Solid State 62, 1033 (2020).

Funding

This work was supported by the Program of the President of the Russian Federation for the state support of leading scientific schools of the Russian Federation, project no. NSh-2644.2020.2. The work was performed within the framework of the state assignment of the Institute of Problems of Chemical Physics, Russian Academy of Sciences, project no. AAAAA19-119111390022-2.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

The authors declare that they have no conflicts of interest.

Additional information

Translated by O. Zhukova

Rights and permissions

About this article

Cite this article

Morgunov, R.B., Bakhmet’ev, M.V. & Talantsev, A.D. A Decrease in the Exchange Bias Caused by an Increase in the Effective Thickness of the Copper Layer in the NiFe/Cu/IrMn Heterostructures. Phys. Solid State 62, 1991–1997 (2020). https://doi.org/10.1134/S1063783420110207

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S1063783420110207