Abstract

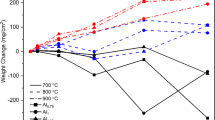

The effect of severe plastic deformation under high-pressure torsion (HPT) on the structural properties of rapidly quenched alloys belonging to the quasi-binary TiNi–TiCu system containing 30 at % of copper was studied. The studies were performed by scanning electron microscopy, X-ray diffraction analysis, and differential scanning calorimetry. Structural studies have demonstrated that the high-pressure torsion of the amorphous Ti50Ni20Cu30 alloy leads to the partial nanocrystallization of its amorphous state. An increase in the strain value leads to an appreciable change in the character of crystallization in the DSC curves. The crystallization peaks split in the region of lower temperatures; i.e., the regions of possible low-temperature crystallization are formed. It has been established that high-pressure torsion decreases the crystallization heat of alloys with a high copper content after heating with respect to their initial amorphous state obtained after melt quenching. After DSC crystallization, the structure heterogeneous in a specimen cross section with stratification of its structural elements by sizes was formed in the alloy. The structure formed in the regions of the partial nanocrystallization of the amorphous state after crystallization was more finely grained than the structure in the major specimen volume. The obtained results convincingly demonstrate the effect of high-pressure torsion on the formation of a crystalline structure from the amorphous Ti50Ni20Cu30 alloys.

Similar content being viewed by others

REFERENCES

G. Karthik, B. Kashyap, and T. R. Prabhu, Mater. Today: Proc. 4, 3581 (2017).

Q. Sun, R. Matsui, K. Takeda, and E. A. Pieczyska, Advances in Shape Memory Materials (AG Springer, Berlin, 2017), p. 245.

J. M. Jani, M. Leary, A. Subic, and M. A. Gibson, Mater. Des. 56, 1078 (2014).

B. C. L. Pedro and A. S. Marcelo, Aerospace Sci., Technol. 76, 155 (2018).

R. Kedare, V. Nanavare, S. Sharma, A. Midathada, and U. K. Ravella, Mater. Today: Proc. 5, 28313 (2018).

N. Choudhary and D. Kaur, Sens. Actuators, A 242, 162 (2016).

C. Velmurugan, V. Senthilkumar, S. Dinesh, and D. Arulkirubakaran, Mater. Today: Proc. 5, 14597 (2018).

A. Shelyakov, N. Sitnikov, A. Menushenkov, and V. Fo-minski, Acta Phys. Polon. 134, 708 (2018).

S. P. Belyaev, V. V. Istomin-Kastrovskiy, V. V. Koledov, D. S. Kuchin, and S. E. Ivanov, Phys. Proc. 10, 39 (2010).

N. Sitnikov, A. Shelyakov, R. Rizakhanov, N. Mitina, and I. Khabibullina, Mater. Today: Proc. 4, 4680 (2017).

N. N. Sitnikov, A. V. Shelyakov, I. A. Khabibullina, and K. A. Borodako, Bull. Russ. Acad. Sci.: Phys. 82, 1106 (2018).

A. V. Shelyakov, N. N. Sitnikov, A. P. Menushenkov, V. V. Koledov, and A. I. Irjak, Thin Solid Films 519, 5314 (2011).

A. Shelyakov, N. Sitnikov, I. Khabibullina, N. Tabachkova, V. Fominski, and N. Andreev, Mater. Lett. 248, 48 (2019).

A. M. Glezer, L. S. Metlov, R. V. Sundeev, and A. V. Shalimova, JETP Lett. 105, 332 (2017).

K. Edalati and Z. Horita, Mater. Sci. Eng. A 652, 325 (2016).

R. V. Sundeev, A. V. Shalimova, A. A. Veligzhanin, A. M. Glezer, and Y. V. Zubavichus, Mater. Lett. 214, 115 (2018).

A. Lukyanova, N. Kuranova, A. Pushin, V. Pushin, and D. Gunderov, Mater. Today: Proc. 4, 4846 (2017).

A. M. Glezer, R. V. Sundeev, and A. V. Shalimova, Rev. Adv. Mater. Sci. 54, 93 (2018).

Funding

This work was financially supported by the Russian Foundation for Basic Research (project no. 18-02-00805 A) and the Russian Science Foundation (project no. 19-72-00145).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

The authors declare that they have no conflicts of interest.

Additional information

Translated by E. Glushachenkova

Rights and permissions

About this article

Cite this article

Sitnikov, N.N., Shelyakov, A.V., Sundeev, R.V. et al. Crystallization Features of Rapidly Quenched Ti50Ni20Cu30 Amorphous Alloys after High-Pressure Torsion. Phys. Solid State 62, 733–738 (2020). https://doi.org/10.1134/S1063783420050285

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S1063783420050285