Abstract—

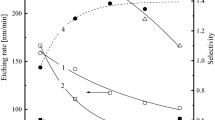

The peculiarities of etching 4H silicon carbide (4H-SiC) in F-containing inductively-coupled plasma at lowered values of power absorbed in an RF discharge are considered. The application of the initial SF6/O2 mixture yielded the most promising results in order to achieve a defect-free morphology of the etching surface of SiC. The influence of bias voltage applied to the substrate holder on the etching rate is identified. The maximum rate of etching in our experiments was 840 nm/min. It is shown that the additional treatment of SiC surface in Ar plasma positively affects the morphology of the etching surface, minimizing the surface density of various defects.

Similar content being viewed by others

REFERENCES

Ivanov, P.A. and Chelnokov, V.E., Semiconductor silicon carbide—technology and devices, overview, Semiconductors, 1995, vol. 29, no. 11, pp. 1003–1013.

Turkin, A., Overview of the development of semiconductor heterostructures based on gallium nitride (GAN), Poluprovodn. Svetotekh., 2011, vol. 6, no. 14, pp. 6–9.

Gol’tsova, M., Power semiconductor electronics. Holding much promise technology becomes a reality, Elektron.: NTB, 2014, no. 4, pp. 54–71.

Rosker, M., Bozada, C., Deitrich, H., Hung, A., Via, D., Binari, S., Vivierios, E., Cohen, E., and Hodiak, J., The DARPA wide band gap semiconductors for RF applications (WBGS-RF) program: phase II results, in Proceedings of the International CS MANTECH Conference, May 18–21, 2009, Tampa, FL.

Jin, H., Qin, L., Zhang, L., Zeng, X., and Yang, R., Review of wide band-gap semiconductors technology, MATEC Web of Conf., 2016, vol. 40, p. 01006.

Capano, M.A. and Trew, R.J., Silicon carbide electronic materials and devices, MRS Bull., 1997, vol. 22, no. 3, pp. 19–23.

Seidman, L.A., Formation of three-dimensional structures in silicon carbide substrates by plasmochemistry etching, Izv. Vyssh. Uchebn. Zaved., Mater. Elektron. Tekh., 2015, vol. 18, no. 3, pp. 157–171.

Osipov, K.Yu. and Velikovskiy, L.E., Formation technology of through metallized holes to sources of high-power GaN/SiC high electron mobility transistors, Semiconductors, 2012, vol. 46, no. 9, pp. 1216–1220.

Ekinci, H., Kuryatkov, V.V., Mauch, D.L., Dickens, J.C., and Nikishin, S.A., Plasma etching of n-type 4H- SiC for photoconductive semiconductor switch applications, J. Electron. Mater., 2015, vol. 44, no. 5, pp. 1300–1305.

Voss, L.F., Ip, K., Pearton, S.J., Shul, R.J., Overberg, M.E., Baca, A.G., Sanchez, C., Stevens, J., Martinez, M., Armendariz, M.G., and Wouters, G.A., SiC via fanrication for wide-band-gap high electron mobility transistor/microwave monolithic integrated circuit devices, J. Vac. Technol. B, 2008, vol. 26, no. 2, pp. 487–494.

Okamoto, N., Ohki, T., Masuda, S., Kanamura, M., Inoue, Y., Makiyama, K., Imanishi, K., Shigematsu, H., Kikkawa, T., Joshin, K., and Hara, N., SiC backside via-hole process for GaN HEMT MMICs using high etch rate ICP etching, in Proceedings of the International CS MANTECH Conference, May 18–21, 2009, Tampa, FL.

Jiang, L., Cheung, R., Brown, R., and Mount, A., Inductively coupled plasma etching of SiC in SF6/O2 and etch-induced chemical bonding modifications, J. Appl. Phys., 2003, vol. 93, no. 3, pp. 1376–1383.

Jiang, L. and Cheung, R., Impact of Ar addition to inductively coupled plasma etching of SiC in SF6/O2, Microelectron. Eng., 2004, vols. 73–74, pp. 306–311.

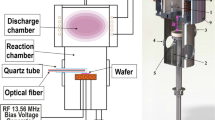

Osipov, A.A., Alexandrov, S.E., and Osipov, Ar.A., Optimization of technological parameters in plasma chemical etching of quartz single crystals, Russ. J. Appl. Chem., 2016, vol. 89, no. 6, pp. 865–870.

Kathalingam, A., Kim, M.-R., Chae, Y.-S., Sudhakar, S., Mahalingam, T., and Rhee, J.-K., Self assembled micro masking effect in the fabrication of SiC nanopillars by ICP-RIE dry etching, Appl. Surf. Sci., 2011, vol. 257, no. 9, pp. 3850–3855.

Kim, D.W., Lee, H.Y., Park, B.J., Kim, H.S., Sung, Y.J., Chae, S.H., Ko, Y.W., and Yeom, G.Y., High rate etching of 6H-SiC in SF6-based magnetically-enhanced inductively coupled plasmas, Thin Solid Films, 2004, vols. 447–448, pp. 100–104.

Plank, N.O.V., Blauw, M.A., van der Drift, E.W.J.M., and Cheung, R., The etching of silicon carbide in inductively coupled SF6/O2 plasma, J. Phys. D: Appl. Phys., 2003, vol. 36, no. 5, pp. 482–487.

Okamoto, N., Elimination of pillar associated with micropipe of SiC in high-rate inductively coupled plasma etching, J. Vac. Sci. Technol., A, 2009, vol. 27, no. 2, pp. 295–300.

Choi, J.H., Latu-Romain, L., Bano, E., Dhalluin, F., Chevolleau, T., and Baron, T., Fabrication of SiC nanopillars by inductively coupled SF6/O2 plasma etching, J. Phys. D: Appl. Phys., 2012, vol. 45, no. 23, p. 235204.

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated by I. Melekestseva

Rights and permissions

About this article

Cite this article

Osipov, A.A., Aleksandrov, S.E., Solov’ev, Y.V. et al. Etching of SiC in Low Power Inductively-Coupled Plasma. Russ Microelectron 47, 427–433 (2018). https://doi.org/10.1134/S1063739719010074

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S1063739719010074