Abstract

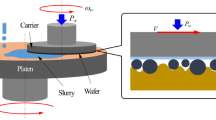

A new model of the interaction of an active suspension with a copper surface during the process of the chemical-mechanical polishing (CMP) of the copper metallization is developed. The manner of the formation and growth of the passivation layer is entered and quantitatively examined for the first time, and its impact on the polishing rate is analyzed. The main stages of the chemical effect of the suspension entered in the models are investigated: diffusion of Cu+ ions and tunneling of the conduction electrons of copper through the passivation layer to its boundary with the suspension and also the chemical reactions in the suspension near the surface of the passivation layer, resulting, on the one hand, in an increase of its thickness, and, on the other hand, in its decrease due to the formation of soluble copper compounds and their removal from the reaction zone. The results are used to describe the CMP of the surface of the copper metallization in the (K3Fe(CN)6 + NH4OH) suspension. The closed system of kinetic equations of the CMP, including a description of the variation with time of the thickness of the passivation layer is obtained; the solutions of this system in the steady-state mode, in the cases of practical importance, when either the diffusion of the Cu+ ions in the passivation layer or their electromigration are predominant are found and analyzed. Estimations of the polishing rate and maximal thicknesses of the passivation layer consistent with the experimental data are obtained.

Similar content being viewed by others

References

Babu, S., Advances in Chemical Mechanical Planarization (CMP). Cambridge: Woodhead, 2016.

Zhao, D. and Lu, X., Chemical mechanical polishing: theory and experiment. Friction, 2013, vol. 1, no. 4, pp. 306–326.

Goldstein, R.V., Makhviladze, T.M., and Sarychev, M.E., Characteristics of the kinetics of periodic structures CMP for a nonlinear pressure dependence of the polishing rate. Russ. Microelectron., 2016, vol. 45, no. 4, pp. 270–277.

Lee, H., Zhuang, Y., Borucki, L., Joh, S., O’Moore, F., and Philipossian, A., Investigation of pad staining and its effect on removal rate in copper chemical mechanical planarization. Thin Solid Films, 2010, vol. 519, no. 1, pp. 259–264.

Krishnan, M., Nalaskowsk, J.W., and Cook, L.M., Chemical mechanical planarization: slurry chemistry, materials, and mechanisms. Chem. Rev., 2010, vol. 110, pp. 178–204.

Balakumar, S., Haque, T., Kumar, S.A., Rahman, M., and Kumar, R., Wear phenomena in abrasive-free copper CMP process. J. Electrochem. Soc., 2005, vol. 152, no. 11, pp. G867–G874.

Steigerwald, J.M., Murarka, S.P., and Gutmann, R.J., Chemical Mechanical Planarization of Microelectronic Materials. New York: Wile-VCH, 2004.

Romagna, F., Febvre, D., and Fayolle, M., Copper CMP evaluation: slurry chemical effect on planarization, in Proceedings of the Conference on Advanced Metallization and Interconnect Systems ULSI 12. Mater. Res. Soc., 1997, pp. 547–553.

Goldstein, R.V., Makhviladze, T.M., and Sarychev, M.E., A new model for the copper cmp kinetics. Proc. SPIE, 2008, vol. 7025, p. 70251Q.

Jiao, Y., Liao, X., Wu, C., Theng, S., Zhuang, Y., Sampurno, Y., Goldstein, M., and Philipossian, A., Tribological, thermal and kinetic attributes of 300 vs. 450 mm chemical mechanical planarization processes. J. Electrochem. Soc., 2012, vol. 159, no. 3, pp. H255–H259.

Sukharev, V., Fluctuation model of chemical mechanical planarization. J. Electrochem. Soc., 2001, vol. 148, no. 3, pp. G172–G177.

Sundararajan, S., Thakurta, D.G., Schwendeman, D.W., et al., Two-dimensional wafer-scale chemical mechanical planarization models based on lubrication theory and mass transport. J. Elecrochem. Soc., 1999, vol. 146, no. 2, pp. 761–766.

Kaufman, F.B., Thomson, D.B., Broadie, R.E., Jaso, M.A., Guthrie, W.L., Pearsons, D.J., and Small, M.B., Chemical–mechanical polishing for fabricating patterned W metal features as chip interconnects. J. Electrochem. Soc., 1991, vol. 138, no. 11, pp. 3460–3465.

Steigerwald, J.M., Murarka, S.P., Ho, J., et al., Mechanisms of copper removal during chemical mechanical polishing. J. Vac. Sci. Technol., 1995, vol. 13, no. 6, pp. 2215–2220.

Landau, L.D. and Lifshits, E.M., Kvantovaya mekhanika (Course of Theoretical Physics, Vol. 3: Quantum Mechanics: Non-Relativistic Theory), Moscow: Nauka, 1976; New York: Pergamon, 1977.

Emmanuel’, N.M. and Knorre, D.G., Kurs khimicheskoi kinetiki (Course of Chemical Kinetics), Moscow: Vysshaya Shkola, 1984.

Landau, L.D. and Lifshits, E.M., Statisticheskaya fizika (Course of Theoretical Physics, Vol. 5: Statistical Physics), Moscow: Nauka, 1976; Oxford: Pergamon, 1980.

Luo, Q., Fury, M.A., and Babu, S.V., Chemical mechanical polishing of copper: a comparative analisis, in Proceedings of the Chemical Mechanical Polishing Multi-Interconnect Conference CMP-MIC, Santa Clara, CA,1997, pp. 83–90.

Valiev, K.A., Makhviladze, T.M., and Sarychev, M.E., Mechanism of plasma-chemical etching of polymers. Dokl. Akad. Nauk SSSR, 1985, vol. 283, no. 2, pp. 366–369.

Valiev, K.A., Makhviladze, T.M., and Sarychev, M.E., Surface effects in photo-etching of polymeric films. Mikroelektronika, 1985, vol. 14, no. 4, pp. 291–300.

Valiev, K.A., Makhviladze, T.M., and Sarychev, M.E., The model of manifestation of polymer resistors. Mikroelektronika, 1992, vol. 21, no. 5, pp. 45–54.

Author information

Authors and Affiliations

Corresponding author

Additional information

Original Russian Text © T.M. Makhviladze, M.E. Sarychev, 2018, published in Mikroelektronika, 2018, Vol. 47, No. 5.

Rights and permissions

About this article

Cite this article

Makhviladze, T.M., Sarychev, M.E. The Model of the Process of the Chemical Mechanical Polishing of the Copper Metallization, Based on the Formation of the Passivation Layer. Russ Microelectron 47, 344–353 (2018). https://doi.org/10.1134/S1063739718050050

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S1063739718050050