Abstract

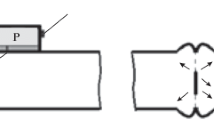

We consider the procedure of ultrasonic quality control of weld seams in thin-walled titanium-alloy shells with a thickness of 0.6 mm. Publications devoted to the excitation and propagation of Lamb waves and practical problems of ultrasonic inspection of thin-walled products are reviewed. The problem of detecting adhesions (areas of a weld seam with lack of penetration that conduct ultrasonic waves well but do not provide mechanical strength) is solved. It is proposed to use a corner groove as an indicator of lack of penetration in the weld. The propagation of different modes of Lamb waves in the material is analyzed, and the optimal testing parameters are selected. High information content of the signal is achieved using wavelet analysis and fine-pitch precision digital filters. Defectograms of a weld containing defective and defect-free areas are analyzed. The results of ultrasound scanning are compared with metallography data.

Similar content being viewed by others

REFERENCES

Bergmann, L., Der Ultraschall und seine Anwendung in Wissenschaft und Technik, Zürich, 1954.

Viktorov, I.A., Fizicheskie osnovy primeneniya ul’trazvukovykh voln Releya i Lemba v tekhnike (Physical Foundations of Application of Rayleigh and Lamb Ultrasonic Waves in Technology), Moscow: Nauka, 1966.

Brekhovskikh, L.M., Volny v sloistykh sredakh (Waves in Layered Media), Moscow: Nauka, 1973.

Vinogradova, M.B., Rudenko, O.V., and Sukhorukiy, A.P., Teoriya voln (Wave theory), Moscow: Nauka, 1979.

Kino, S., Acoustic Waves, Englewood Cliffs, NJ: Prentice-Hall, 1987.

Krautkremer, I. and Krautkremer, G., Ul’trazvukovoi kontrol’ materialov (Ultrasonic Inspection of Materials), Moscow: Metallurgiya, 1991.

Shcherbinskii, V.G. and Aleshin, N.P., Ul’trazvukovoi kontrol’ svarnykh soedinenii (Ultrasonic Testing of Welded Joints), Moscow: Izd. Mosk. Gos. Tekh. Univ. im. N.E. Bauman, 2000, 3rd ed.

Nerazrushayuschiy kontrol’. Spravochnik v 8 tomakh (Nondestructive Testing—A Handbook in Eight Volumes), Klyuev, V.V., Ed., Moscow: Mashinostroenie, 2008, vol. 3.

Deryabin, A.A., Development of criteria for assessing the types of defects in welded joints of thin-walled pipes by Lamb waves, Cand. Sci. (Eng.) Dissertation, Moscow: Bauman Moscow State Technical University, 2008.

Loshitskii, A.R., Theoretical studies of the propagation of Lamb waves in elastic plates, Cand. Sci. (Eng.) Dissertation, Moscow: ZAO TsNIIOMTP, 2001.

Korobov, A.I. and Izosimova, M.Yu., Nonlinear Lamb waves in a metal plate with defects, Acoust. Phys., 2006, vol. 52, no. 5, pp. 589–597.

Kuznetsov, S.V., Lamb waves in anisotropic plates (review), Acoust. Phys., 2014, vol. 60, no. 1, pp. 95–103.

Il’yashenko, A.V. and Kuznetsov, S.V., Theoretical Aspects of Applying Lamb Waves in Nondestructive Testing of Anisotropic Media, Russ. J. Nondestr. Test., 2017, vol. 53, no. 4, pp. 243–259.

Perov, D.V. and Rinkevich, A.B., Localization of reflectors in plates by ultrasonic testing with lamb waves, Russ. J. Nondestr. Test., 2017, vol. 53, no. 4, pp. 265–278.

Burkov, M.V., Eremin, A.V., Lyubutin, P.S., Byakov, A.V., and Panin, S.V., Applying an ultrasonic Lamb wave based technique to testing the condition of V96ts3T12 aluminum alloy, Russ. J. Nondestr. Test., 2017, vol. 53, no. 12, pp. 817–829.

Kazakov, V.V., Detection and determination of the position of a crack in a plate by a nonlinear modulation method using Lamb waves, Izv. Vyssh. Uchebn. Zaved. Radiofiz., 2018, vol. 61, no. 7, pp. 555–565.

Burkov, M.V., Lyubutin, P.S., and Byakov, A.V., Lamb wave ultrasonic detection of barely visible impact damages of CFRP, Russ. J. Nondestr. Test., 2019, vol. 55, no. 2, pp. 89–101.

Aversheva, A.V. and Kuznetsov, S.V., Numerical modeling of the propagation of Lamb waves in an isotropic layer, Int. J. Comput. Civ. Struct. Eng., 2019, vol. 15, no. 2, pp. 14–23.

Barkhatov, V.A., Development of methods of ultrasonic nondestructive testing of welded joints, Russ. J. Nondestr. Test., 2003, vol. 39, no. 1, pp. 23–47.

Aleshin, N.P. and Deryabin, A.A., Development of criteria for assessing the types of defects in welded joints of thin-walled pipes by Lamb waves, Kontrol’. Diagn., 2008, no. 2, pp. 30–33.

Burkin, S.P., Serebryakov, A.V., Markov, A.D., and Serebryakov, A.V., Improvement of the technique of ultrasonic testing of small-diameter pipes, Zavod. Lab., Diagn. Mater., 2012, vol. 78, no. 12, pp. 45–49.

Deryabin, A.A., Remizov, A.L., and Prilutsky, M.A., Solid-state model of diffraction of Lamb waves in the presence of crack-like defects, Aktual. Probl. Gumanitarnykh Estestv. Nauk., 2013, no. 11-1, pp. 98–106.

Deryabin, A.A., Remizov, A.L., and Prilutsky, M.A., Solid-state model of diffraction of Lamb waves in the presence of volumetric defects, Aktual. Probl. Gumanitarnykh Estestv. Nauk., 2013, no. 12-1, pp. 77–82.

Burkov, M.V., Panin, S.V., Byakov, A.V., Lyubutin, P.S., and Eremin, A.V., Application of the ultrasonic method using Lamb waves for monitoring the state of aluminum alloys. Part 1. Static mechanical tests, Izv. Vyssh. Uchebn. Zaved. Fiz., 2015, vol. 58, no. 6-2, pp. 25–30.

Burkov, M.V., Panin, S.V., Byakov, A.V., Lyubutin, P.S., and Eremin, A.V., Application of the ultrasonic method using Lamb waves for monitoring the state of aluminum alloys. Part 2. Cyclic mechanical tests, Izv. Vyssh. Uchebn. Zaved. Fiz., 2015, vol. 58, no. 6-2, pp. 31–35.

Kopytov, D.V., Kuznetsov, M.N., Babenkov, M.V., and Gurevich, D.V., Experience in the use of ultrasonic scanning using Lamb waves when inspecting the bottoms of tanks, Avtom., Telemekh. Svyaz Neft. Prom-sti., 2015, no. 12, pp. 4–6.

Murav’eva, O.V. and Murav’ev, V.V., Methodological peculiarities of using SH- and Lamb waves when assessing the anisotropy of properties of flats, Russ. J. Nondestr. Test., 2016, vol. 52, no. 7, pp. 363–369.

Murav’ev, V.V., Murav’ieva, O.V., and Volkova, L.V., Influence of anisotropy of mechanical properties of thin-rolled steel rolled stock on informative parameters of Lamb waves, Stal’, 2016, no. 10, pp. 75–79.

Evdokimov, A.A., Distribution and motion of the roots of the dispersion equation for Lamb waves in the complex plane, Ekol. Vestn. Nauchn. Tsentrov. Chern. Ekon. Sodruzhestva, 2017, no. 3, pp. 30–37.

Nirbhay, M., Dixit, A., and Misra, R.K., Finite element modelling of Lamb waves propagation in 3D plates and brass tubes for damage detection, Russ. J. Nondestr. Test., 2017, vol. 53, no. 4, pp. 308–329.

Iskhuzhin, R.R. and Atavin, V.G., Determination of the optimal angle of excitation of Lamb waves using a phased antenna array, XXI Vserossiiskaya konferentsiya po nerazrushayuschemu kontrolyu I tekhnicheskoi diagnostike: sbornik trudov (XXI All-Russ. Conf. Nondestr. Test. Tech. Diagn. Proc.), Moscow: Spektr, 2017.

Gurevich, S.Yu., Petrov, Yu.V., and Golubev, E.V., Thickness gauging of thin metalware with ultrasound excited by laser nanopulses, Russ. J. Nondestr. Test., 2018, vol. 54, no. 3, pp. 147–150.

Ze-Yu Don, Hai-Tao Wang, Xian-Ming Yang, Xin Li, Jun Shu, and Meng Hao Jiang, Research for evaluation method based on Lamb waves for thickness of ship deck beams, Russ. J. Nondestr. Test., 2020, vol. 56, no. 7, pp. 556–565.

Grigorievsky, V.I., Kozlov, A.I., Plessky, V.P., and Tereshkov, V.P., Calculation of dispersion curves of Lamb modes in YZ-cut lithium niobate plates, Akust. Zh., 1985, vol. 37, no. 1, pp. 42–44.

Barkhatov, V.A., Solution of the one-dimensional inverse acoustic problem with allowance for velocity dispersion and frequency-dependent wave attenuation, Russ. J. Nondestr. Test., 2009, vol. 45, no. 1, pp. 29–39.

Terent’ev, D.A. and Popkov, Y.S., Determination of the parameters of the dispersion curves of Lamb waves with the use of the Hough transform of the spectrogram of an AE signal, Russ. J. Nondestr. Test., 2014, vol. 50, no. 1, pp. 19–28.

Zakharov, D.D., Parametric analysis of complex dispersion curves for flexural Lamb waves in layered plates in the low-frequency range, Acoust. Phys., 2018, vol. 64, no. 4, pp. 387–401.

Hu, Y., Zhu, Y., Tu, X., Lu, J., and Li, F., Dispersion curve analysis method for Lamb wave mode separation, Struct. Health Monit., 2020, vol. 19, no. 5, pp. 1590–1601. https://doi.org/10.1177/1475921719890590

Zima, B. and Kedra, R., Numerical study of concrete mesostructure effect on lamb wave propagation, Materials, 2020, vol. 13, no. 11. https://doi.org/10.3390/ma13112570

Zhang, Y., Qian, Z., and Wang, B., Modes control of Lamb wave in plates using meander-line electromagnetic acoustic transducers, Appl. Sci. (Switzerland), 2020, vol. 10, no. 10. https://doi.org/10.3390/app10103491

Iskhuzhin, R. R., Borisov, V. N., Atavin, V. G., Uzkikh, A. A., and Khafizova, K. K., Ultrasonic testing of thinwalled titanium weld joint with adhesion detector, J. Phys.: Conf. Ser., vol. 1636. https://doi.org/10.1088/1742-6596/1636/1/012004

Gao, F., Wang, L., Hua, J., Lin, J., and Mal, A., Application of Lamb wave and its coda waves to disband detection in an aeronautical honeycomb composite sandwich, Mech. Syst. Sign. Proc., 2021, vol. 146, p. 107063. https://doi.org/10.1016/j.ymssp.2020.107063

He, J., Huo, H., Guan, X., and Yang, J., A Lamb wave quantification model for inclined cracks with experimental validation, Chin. J. Aeronaut., 2020. https://doi.org/10.1016/j.cja.2020.02.010

Hua, J., Cao, X., Yi, Y., and Lin, J., Time-frequency damage index of Broadband Lamb wave for corrosion inspection, J. Sound Vib., vol. 464, p. 114985. https://doi.org/10.1016/j.jsv.2019.114985

Zhang, Z., Pan, H., Wang, X., and Lin, Z., Machine learning-enriched lamb wave approaches for automated damage detection, Sensors (Switzerland), 2020, no. 20 (6), p. 1790. https://doi.org/10.3390/s20061790

Zhu, W.G., Li, Y.F., Guan, L.Q., Wan, X.L., Yu, H.Y., and Liu, X.Z., Micro-crack detection of nonlinear Lamb wave propagation in three-dimensional plates with mixed-frequency excitation, Chin. Phys. B, vol. 29, no. 1, p. 014302. https://doi.org/10.1088/1674-1056/ab5931

Jiao, P., Egbe, K.-J.I., Xie, Y., Matin Nazar, A., and Alavi, A.H., Piezoelectric sensing techniques in structural health monitoring: a state-of-the-art review, Sensors (Switzerland), 2020, vol. 20, no. 13, p. 3730. https://doi.org/10.3390/s20133730

Rébillat, M. and Mechbal, N., Damage localization in geometrically complex aeronautic structures using canonical polyadic decomposition of Lamb wave difference signal tensors, Struct. Health Monit., 2020, vol. 19, no. 1, pp. 305–321. https://doi.org/10.1177/1475921719843453

Wan, T., Chang, J., Zeng, X., and Li, Y., Damage identification and scanning imaging of glass fiber reinforced polymer composite plates based on empirical mode decomposition and correlation coefficient. Fuhe Cailiao Xuebao, Acta Mater. Compos. Sin., 2020, vol. 37, no. 8, pp. 1921–1931. https://doi.org/10.13801/j.cnki.fhclxb.20191031.003

Fromme, P., Guided wave sensitivity prediction for part and through-thickness crack-like defects, Struct. Health Monit., 2020, vol. 19, no. 3, pp. 953—963. https://doi.org/10.1177/1475921719892205

Liu, B., Liu, T., Zhao, J., and Hang, D., Frequency Aliasing-Based Spatial-Wavenumber Filter for Online Damage Monitoring, Shock Vib., 2020. https://doi.org/10.1155/2020/8856241

Xiao, W., Yu, L., Joseph, R., and Giurgiutiu, V., Fatigue-crack detection and monitoring through the scattered wave two-dimensional cross-correlation imaging method using piezoelectric transducers, Sensors (Switzerland), 2020, vol. 20, no. 11, p. 3035. https://doi.org/10.3390/s20113035

Hu, C., Yang, B., Xuan, F. Z., Yan, J., and Xiang, Y., Damage orientation and depth effect on the guided wave propagation behavior in 30CrMo steel curved plates, Sensors (Switzerland), 2020, vol. 20, no. 3, p. 849. https://doi.org/10.3390/s20030849

Chen, B., Wang, C., Wang, P., Zheng, S., and Sun, W., Research on fatigue damage in high-strength steel (FV520B) using nonlinear ultrasonic testing, Shock Vib., 2020. https://doi.org/10.1155/2020/8847704

Ewald, V., Groves, R., and Benedictus, R., Integrative approach for transducer positioning optimization for ultrasonic structural health monitoring for the detection of deterministic and probabilistic damage location, Struct. Health Monit., 2020. https://doi.org/10.1177/1475921720933172

Serey, V., Quaegebeur, N., Renier, M., Micheau, P., Masson, P., and Castaings, M., Selective generation of ultrasonic guided waves for damage detection in rectangular bars, Struct. Health Monit., 2020. https://doi.org/10.1177/1475921720947407

Nicassio, F., Carrino, S., and Scarselli, G., Non-linear Lamb Waves for Locating Defects in Single-Lap Joints, Front. Built Env., 2020, no. 6 (45). https://doi.org/10.3389/fbuil.2020.00045

Dafydd, I. and Sharif Khodaei, Z., Analysis of barely visible impact damage severity with ultrasonic guided Lamb waves, Struct. Health Monit., 2020, vol. 19, no. 4, pp. 1104–1122. https://doi.org/10.1177/1475921719878850

Li, J., Sharif Khodaei, Z., and Aliabadi, M. H., Boundary element modelling of ultrasonic Lamb waves for structural health monitoring, Smart Mater. Struct., 2020, vol. 29, no. 10, p. 105030. https://doi.org/10.1088/1361-665x/aba6ce

Liu, Y., He, A., Liu, J., Mao, Y., and Liu, X., Location of micro-cracks in plates using time reversed nonlinear Lamb waves, Chin. Phys. B., 2020, vol. 29, no. 5, https://doi.org/10.1088/1674-1056/ab81f7

Xu, C., Yang, Z., Qiao, B., and Chen, X., A parameter estimation based sparse representation approach for mode separation and dispersion compensation of Lamb waves in isotropic plate, Smart Mater. Struct., 2020, vol. 29, no. 3, p. 035020. https://doi.org/10.1088/1361-665x/ab6ce7

Chen, X. and Ni, L., Mode separation for multimode Lamb waves overlapped in time and frequency domains by using fractional differential. Shengxue Xuebao, Acta Acustica, 2020, vol. 45, no. 2, pp. 205–214. https://doi.org/10.7498/aps.67.20180561

He, C., Ren, Z., Lyu, Y., Gao, J., Wang, S., and Song, G., Reflection/transmission characteristics based on Legendre orthogonal polynomial method, Beijing Hangkong Hangtian Daxue Xuebao, 2020, vol. 46, no. 7, pp. 1258–1266. https://doi.org/10.13700/j.bh.1001-5965.2019.0434

Attar, L., Leduc, D., Ech Cherif El Kettani, M., Predoi, M. V., Galy, J., and Pareige, P., Detection of the degraded interface in dissymmetrical glued structures using Lamb waves, NDT & E Int., 2020, vol. 111. p. 102213. https://doi.org/10.1016/j.ndteint/2019/102213

Ismail, N., Hafizi, Z.M., Nizwan, C.K.E., and Ali, S., Interactions of Lamb waves with defects in a thin metallic plate using the finite element method, in Advances in Mechatronics, Manufacturing, and Mechanical Engineering. Lecture Notes in Mechanical Engineering, Zakaria, M., Abdul Majeed, A., and Hassan, M., Eds., Singapore: Springer, 2021. https://doi.org/10.1007/978-981-15-7309-5_19

Tie, Y., Zhang, Q., Hou, Y., and Li, C., Impact damage assessment in orthotropic CFRP laminates using nonlinear Lamb wave: Experimental and numerical investigations, Compos. Struct., 2020. https://doi.org/10.1016/j.compstruct.2020.111869

Chen, H., Zhang, G., Fan, D., Fang, L., and Huang, L., Nonlinear Lamb wave analysis for microdefect identification in mechanical structural health assessment. Measurement, J. Int. Measur. Confed., 2020, vol. 164, p. 108026. https://doi.org/10.1016/j.measurement.2020.108026

Zhou, K., Xu, X., and Wu, Z., Damage detection with single mode lamb wave based on piezoelectric transducers, Yadian Yu Shengguang, 2020, vol. 42, no. 1, pp. 38–41. https://doi.org/10.11977/j.issn.1004-2474.2020.01.010

Haider, M. F., Joseph, R., Giurgiutiu, V., and Poddar, B., An efficient analytical global–local (AGL) analysis of the Lamb wave scattering problem for detecting a horizontal crack in a stiffened plate, Acta Mechanica, 2020, vol. 231, no. 2, pp. 577–596. https://doi.org/10.1007/s00707-019-02555-z

Liu, H., and Zhang, Y., Deep learning based crack damage detection technique for thin plate structures using guided lamb wave signals, Smart Mater. Struct., 2020, vol. 29, no. 1, p. 015032. https://doi.org/10.1088/1361-665X/ab58d6

Borate, P., Wang, G., and Wang, Y., Data-driven structural health monitoring approach using guided Lamb wave responses, J. Aerosp. Eng., 2020, vol. 33, no. 4, https://doi.org/10.1061/(ASCE)AS.1943-5525.0001145

Jia, H., Liu, H., Zhang, Z., Dai, F., Liu, Y., and Leng, J., A baseline-free approach of locating defect based on mode conversion and the reciprocity principle of Lamb waves, Ultrasonics, 2020, vol. 102. https://doi.org/10.1016/j.ultras.2020.106063

Tai, S., Kotobuki, F., Wang, L., and Mal, A., Modeling Ultrasonic Elastic Waves in Fiber-Metal Laminate Structures in Presence of Sources and Defects, J. Nondestr. Eval. Diagn. Progn. Eng. Syst., 2020, vol. 3, no. 4. https://doi.org/10.1115/1.4046946

Bahador, M. M., Zaimbashi, A., and Rahgozar, R., Three-stage Lamb-wave-based damage localization algorithm in plate-like structures for structural health monitoring applications, Sign. Process., 2020, vol. 168. https://doi.org/10.1016/j.sigpro.2019.107360

Wang, X., Xiang, Y., Zhu, W. J., Ding, T. T., and Li, H. Y., Damage assessment in Q690 high strength structural steel using nonlinear Lamb waves, Constr. Build. Mat., 2020, vol. 234. https://doi.org/10.1016/j.conbuildmat.2019.117384

Purcel,l F.A., Eaton, M., Pearson, M.R., and Pullin, R., Non-destructive evaluation of isotropic plate structures by means of mode filtering in the frequency-wavenumber domain, Mech. Syst. Sign. Process., 2020, vol. 142, p. 106801. https://doi.org/10.1016/J.YMSSP.2020.106801

Li, J., Lu, Y., and Lee, Y. F., Debonding detection in CFRP-reinforced steel structures using anti-symmetrical guided waves, Compos. Struct., 2020, vol. 253, p. 112813. https://doi.org/10.1016/j.compstruct.2020.112813

Lee, Y.F., Lu, Y., and Guan, R., Nonlinear guided waves for fatigue crack evaluation in steel joints with digital image correlation validation, Smart Mater. Struct., 2020, vol. 29, no. 3, p. 035031. https://doi.org/10.1088/1361-665X/ab6fe7

Alnuaimi, H., Amjad, U., Russo, P., Lopresto, V., and Kundu, T., Monitoring damage in composite plates from crack initiation to macro-crack propagation combining linear and nonlinear ultrasonic techniques, Struct. Health Monit., 2020. https://doi.org/10.1177/1475921720922922

Weiland, J., Hesser, D. F., Xiong, W., Schiebahn, A., Markert, B., and Reisgen, U., Structural health monitoring of an adhesively bonded CFRP aircraft fuselage by ultrasonic Lamb Waves. Proceedings of the Institution of Mechanical Engineers, Part G, J. Aerosp. Eng., 2020. https://doi.org/10.1177/0954410020950511

Lamb-Wave Based Structural Health Monitoring in Polymer Composites, Research Topics in Aerospace, Lammering, R. et al., Eds., Berlin: Springer, 2018. https://doi.org/10.1007/978-3-319-49715-0

Mogil’ner, L.Yu., The use of a cylindrical reflector for adjusting the sensitivity during ultrasonic testing, Defectoskopiya, 2018, no. 7, pp. 27–36.

Mogil’ner, L.Yu., Smorodinskii, Ya.G., Ultrasonic flaw detection: Adjustment and calibration of equipment using samples with cylindrical drilling, Russ. J. Nondestr. Test., 2018, vol. 54, no. 9, pp. 630–637.

GOST 3722-2014. Rolling bearings. Steel balls. Technical conditions, Moscow: Standartinform, 2015.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Iskhuzhin, R.R., Borisov, V.N., Atavin, V.G. et al. Ultrasonic Testing of Welds in Thin-Walled Titanium Shells Using an Incomplete Penetration Indicator. Russ J Nondestruct Test 57, 105–113 (2021). https://doi.org/10.1134/S1061830921020054

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S1061830921020054