Abstract

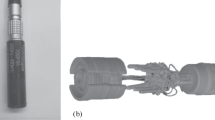

The possibilities of increasing the reliability of eddy-current quality control of soldering in current-carrying copper joints of the stator windings of electrical machines and expanding the nomenclature of inspected joints by using an improved eddy current transducer with a U-shaped core are investigated. To achieve this goal, rectangular cutouts were made in the poles of the U-shaped core, made of transformer steel plates, to allow the transducer to be mounted on a tested solder joint in two mutually perpendicular directions. Using such a transducer for testing allows one to induce closedloop eddy currents in the solder joint along these two directions, thus significantly improving the reliability of testing by virtue of all soldered surfaces in the joint contributing to the eddy-current transducer signal. The use of such a transducer also significantly expands the range of tested joints due to the possibility of exciting closed-loop eddy currents perpendicular to the direction of such joints (testing the side walls of the joints). It is shown that despite local changes in the distribution of electromagnetic field in the interpole space as compared to the case of no cuts, the presence of rectangular cuts in the poles of the U-shaped core of the eddy current transducer practically does not affect the accuracy of determining the degree of soldering of tested joints along and perpendicular to their direction.

Similar content being viewed by others

References

Rozenfel’d, E.V., Nichipuruk, A.P., Kogan, L.Kh., and Khudyakov, B.A., Eddy-current quality control of soldering of current-carrying joints in electrical machines. I. General principles, Russ. J. Nondestr. Test., 2010, vol. 46, no. 4, pp. 281–291.

Kogan, L.K., Nichipuruk, A.P., Rozenfel’d, E.V., and Khudyakov, B.A., Eddy-current quality control of soldering of current-carrying joints in electrical machines. II. Experiment, Russ. J. Nondestr. Test., 2010, vol. 46, no. 4, pp. 292–301.

Kogan, L., Nichipuruk, A., Savary, F., Principe, R., Datskov, V., Rozenfel’d, E., and Khudjakov, B., Eddy current quality of soldered current-carrying bas-bar splices of superconducting magnets, Insight, 2015, vol. 57, no. 12, p. 697 (6 pp.).

Fedosenko, Yu.K., Shkatov, P.N., and Efimov, A.G., Vikhretokovyi kontrol’/Uchebnoe posobie (Eddy Current Testing. A Study Guide), Klyuev, V.V., Ed., Moscow: Spektr, 2011, p. 224.

Syas’ko, V.A., Roitgarts, M.B., Koroteev, M.Yu., and Solomenchuk, P.V., Quality control of soldered joints of stator windings of turbogenerators at the Electrosila plant, V Mire Nerazrushayushchego Kontrolya, 2010, no. 2 (48), pp. 1–9.

Reutov, Yu.Ya., Depth of penetration of the field of a surface eddy current transducer into the product, Elektrichestvo, 2018, no. 4, pp. 50–57.

Author information

Authors and Affiliations

Corresponding author

Additional information

Original Russian Text © L.Kh. Kogan, A.N. Stashkov, A.P. Nichipuruk, 2018, published in Defektoskopiya, 2018, No. 11, pp. 43–48.

Rights and permissions

About this article

Cite this article

Kogan, L.K., Stashkov, A.N. & Nichipuruk, A.P. Improving the Reliability of Eddy-Current Quality Control of Soldering in Current-Carrying Copper Joints and Expanding the Nomenclature of Inspected Joints in Energy Equipment. Russ J Nondestruct Test 54, 784–791 (2018). https://doi.org/10.1134/S1061830918110049

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S1061830918110049