Abstract

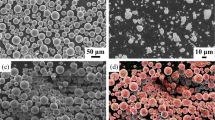

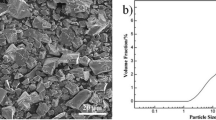

Electron beam additive manufacturing with simultaneous feeding of two dissimilar metal wires was used to obtain Ti-6Al-4V specimens successively alloyed with 0.6, 1.6, 6.0 and 9.7 wt % Cu. The specimens were characterized for microstructure, phases, and mechanical properties. Increasing the copper content in the alloy from 0.6 to 9.7 wt % resulted in the refinement of primary β-Ti grains and the columnar-to-equiaxed grain transformation owing to the effect of constitutional undercooling on grain nucleation and growth. The grain growth restriction factor was calculated to substantiate the microstructural evolution from columnar to equiaxed grains. Admixing with up to 6.0 wt % Cu resulted in the formation of ultrathin α-Ti platelets, while increasing the copper content to 9.7 wt % Cu led not only to further thinning of α-Ti platelets but also to the formation of refined α′-Ti and α″-Ti phases. Intermetallic Ti2Cu particles were precipitated due to the β → Ti2Cu + α eutectoid decomposition of primary β-Ti grains and then plausibly induced heterogeneous nucleation of α-Ti platelets. A combined effect of solid solution hardening, precipitation hardening, and grain boundary hardening was achieved and allowed increasing the microhardness, ultimate tensile stress, tensile yield stress, and compression yield stress of Ti-6Al-4V/Сu specimens.

Similar content being viewed by others

REFERENCES

Froes, F.H.S., Gungor, M.N., and Ashraf Imam, M., Cost-Affordable Titanium: The Component Fabrication Perspective, J. Min. Met. Mat. S., 2007, vol. 59, pp. 28–31. https://doi.org/10.1007/s11837-007-0074-8

Attar, H., Ehtemam-Haghighi, S., Soro, N., Kent, D., and Dargusch, M.S., Additive Manufacturing of Low-Cost Porous Titanium-Based Composites for Biomedical Applications: Advantages, Challenges and Opinion for Future Development, J. Alloys Compnd., 2020, vol. 827, p. 154263. https://doi.org/10.1016/j.jallcom.2020.154263

Brandl, E., Schoberth, A., and Leyens, C., Morphology, Microstructure, and Hardness of Titanium (Ti-6Al-4V) Blocks Deposited by Wire-Feed Additive Layer Manufacturing (ALM), Mater. Sci. Eng. A, 2012, vol. 532, pp. 295–307. https://doi.org/10.1016/j.msea.2011.10.095

Wu, X., Liang, J., Mei, J., Mitchell, C., Goodwin, P.S., and Voice, W., Microstructures of Laser-Deposited Ti–6Al–4V, Mater. Design, 2004, vol. 25(2), pp. 137–144. https://doi.org/10.1016/j.matdes.2003.09.009

Wu, X., Sharman, R., Mei, J., and Voice, W., Direct Laser Fabrication and Microstructure of a Burn-Resistant Ti Alloy, Mater. Design, 2002, vol. 23(3), pp. 239–247. https://doi.org/10.1016/S0261-3069(01)00086-3

Blackwell, P.L. and Wisbey, A., Laser-Aided Manufacturing Technologies; Their Application to the Near-Net Shape Forming of a High-Strength Titanium Alloy, J. Mater. Process. Technol., 2005, vol. 170(1–2), pp. 268–276. https://doi.org/10.1016/j.jmatprotec.2005.05.014

Kobryn, P.A., Moore, E.H., and Semiatin, S.L., The Effect of Laser Power and Traverse Speed on Microstructure, Porosity, and Build Height in Laser-Deposited Ti-6Al-4V, Scripta Mater., 2000, vol. 43(4), pp. 299–305. https://doi.org/10.1016/S1359-6462(00)00408-5

Razorenov, S.V., Garkushin, G.V., Savinykh, A.S., Klimova-Korsmik, O.G., Shalnova, S.A., and Gushchina, M.O., Dynamic Strength of VT6 Titanium Alloy Manufactured by Laser Metal Deposition, Phys. Mesomech., 2022, vol. 25, no. 1, pp. 26–32. https://doi.org/10.1134/S1029959922010040

Kalashnikov, K.N., Chumaevskii, A.V., Kalashnikova, T.A., Osipovich, K.S., and Kolubaev, E.A., Defect Formation in Titanium Alloy during Non-Stationary Process of Local Metallurgy, Russ. Phys. J., 2020, vol. 63, pp. 962–967. https://doi.org/10.1007/s11182-020-02124-1

Antonysamy, A.A., Meyer, J., and Prangnell, P.B., Effect of Build Geometry on the β-Grain Structure and Texture in Additive Manufacture of Ti6Al4V by Selective Electron Beam Melting, Mater. Character., 2013, vol. 84, pp. 153–168. https://doi.org/10.1016/j.matchar.2013.07.012

Al-Bermani, S.S., Blackmore, M.L., Zhang, W., and Todd, I., The Origin of Microstructural Diversity, Texture, and Mechanical Properties in Electron Beam Melted Ti-6Al-4V, Metall. Mater. Trans. A, 2010, vol. 41, pp. 3422–3434. https://doi.org/10.1007/s11661-010-0397-x

Kolubaev, E.A., Rubtsov, V.E., Chumaevsky, A.V., and Astafurova, E.G., Micro-, Meso- and Macrostructural Design of Bulk Metallic and Polymetallic Materials by Wire-Feed Electron-Beam Additive Manufacturing, Phys. Mesomech., 2022, vol. 25, no. 6, pp. 479–491. https://doi.org/10.1134/S1029959922060017

Martina, F., Mehnen, J., Williams, S.W., Colegrove, P., and Wang, F., Investigation of the Benefits of Plasma Deposition for the Additive Layer Manufacture of Ti-6Al-4V, J. Mater. Process. Technol., 2012, vol. 212(6), pp. 1377–1386. https://doi.org/10.1016/j.jmatprotec.2012.02.002

Wang, F., Williams, S., and Rush, M., Morphology Investigation on Direct Current Pulsed Gas Tungsten Arc Welded Additive Layer Manufactured Ti6Al4V Alloy, Int. J. Adv. Manuf. Technol., 2011, vol. 57, pp. 597–603. https://doi.org/10.1007/s00170-011-3299-1

Bermingham, M.J., StJohn, D.H., Krynen, J., Tedman-Jones, S., and Dargusch, M.S., Promoting the Columnar to Equiaxed Transition and Grain Refinement of Titanium Alloys during Additive Manufacturing, Acta Mater., 2019, vol. 168, pp. 261–274. https://doi.org/10.1016/j.actamat.2019.02.020

Mereddy, S., Bermingham, M.J., StJohn, D.H., and Dargusch, M.S., Grain Refinement of Wire Arc Additively Manufactured Titanium by the Addition of Silicon, J. Alloys Compnd., 2017, vol. 695, pp. 2097–2103. https://doi.org/10.1016/j.jallcom.2016.11.049

Mahbooba, Z., West, H., Harrysson, O., Wojcieszynski, A., Dehoff, R., Nandwana, P., and Horn, T., Effect of Hypoeutectic Boron Additions on the Grain Size and Mechanical Properties of Ti-6Al-4V Manufactured with Powder Bed Electron Beam Additive Manufacturing, JOM, 2017, vol. 69, pp. 472–478. https://doi.org/10.1007/s11837-016-2210-9

Tao, X., Yao, Z., Zhang, S., Yao, M., Sun, S., and Moliar, O., Effect of Beam Power on the Distribution Statues of Aligned TiBw and Tensile Behavior of Trace Boron-Modified Ti6Al4V Alloy Produced by Electron Beam Freeform Fabrication, Vacuum, 2020, vol. 172, p. 109070. https://doi.org/10.1016/j.vacuum.2019.109070

Gou, J., Wang, Z., Hu, S., Shen, J., Tian, Y., Zhao, G., and Chen, Y., Effects of Trace Nb Addition on Microstructure and Properties of Ti-6Al-4V Thin-Wall Structure Prepared Via Cold Metal Transfer Additive Manufacturing, J. Alloys Compnd., 2020, vol. 829, p. 0925-8388. https://doi.org/10.1016/j.jallcom.2020.154481

Xiong, Z., Pang, X., Liu, S., Li, Z., and Misra, R.D.K., Hierarchical Refinement of Nickel-Microalloyed Titanium during Additive Manufacturing, Scripta Mater., 2021, vol. 195, p. 113727. https://doi.org/10.1016/j.scriptamat.2021.113727

Wang, X., Zhang, L.J., Ning, J., Li, S., Zhang, L.L., Long, J., and Ma, W., Fe Element Promotes the Transformation from Columnar to Equiaxed Grains and the Formation of Ultrafine Microstructure of Ti-6Al-4V Alloy by Laser Wire Deposition, Addit. Manuf., 2021, vol. 48, part B, p. 102442. https://doi.org/10.1016/j.addma.2021.102442

Zhang, D., Qiu, D., Gibson, M.A., Zheng, Y., Fraser, H.L., StJohn, D.H., and Easton, M.A., Additive Manufacturing of Ultrafine-Grained High-Strength Titanium Alloys, Nature, 2019, vol. 576, pp. 91–95. https://doi.org/10.1038/s41586-019-1783-1

Vilardell, A.M., Yadroitsev, I., Yadroitsava, I., Albu, M., Takata, N., Kobashi, M., Krakhmalev, P., Kouprianoff, D., Kothleitner, G., and du Plessis, A., Manufacturing and Characterization of In-Situ Alloyed Ti6Al4V(ELI)-3 at % Cu by Laser Powder Bed Fusion, Addit. Manuf., 2020, vol. 36, p. 101436. https://doi.org/10.1016/j.addma.2020.101436

Li, X., Yao, Z., Tao, X., Yao, M., and Zhang, S., Developing Cu Modified Ti6Al4V Alloys with a Combination of High Strength and Ductility by Electron Beam Freeform Fabrication, Vacuum, 2021, vol. 194, p. 110638. https://doi.org/10.1016/j.vacuum.2021.110638

Schmid-Fetzer, R. and Kozlov, A., Thermodynamic Aspects of Grain Growth Restriction in Multicomponent Alloy Solidification, Acta Mater., 2011, vol. 59(15), pp. 6133–6144. https://doi.org/10.1016/j.actamat.2011.06.026

Easton, M.A. and StJohn, D.H., A Model of Grain Refinement Incorporating Alloy Constitution and Potency of Heterogeneous Nucleant Particles, Acta Mater., 2001, vol. 49(10), pp. 1867–1878. https://doi.org/10.1016/S1359-6454(00)00368-2

Yang, Y.F., Luo, S.D., and Qian, M., The Effect of Lanthanum Boride on the Sintering, Sintered Microstructure and Mechanical Properties of Titanium and Titanium Alloys, Mater. Sci. Eng. A, 2014, vol. 618, pp. 447–455. https://doi.org/10.1016/j.msea.2014.08.080

Kartavykh, A.V., Asnis, E.A., Piskun, N.V., Statkevich, I.I., Gorshenkov, M.V., and Tcherdyntsev, V.V., Lanthanum Hexaboride as Advanced Structural Refiner/Getter in TiAl-Based Refractory Intermetallics, J. Alloys Compnd., 2014, vol. 588, pp. 122–126. https://doi.org/10.1016/j.jallcom.2013.11.017

Wang, B., Liu, Y., Liu, Y.B., Tang, H.P., Qiu, J.W., and Wang, Y.L., Effects of LaH2 and LaB6 Addition on Microstructure and Mechanical Property of Powder Metallurgy Ti Alloy, Mater. Sci. Eng. Powder Metallurgy, 2011, vol. 16, pp. 136–142.

Kennedy, J.R., Davis, A.E., Caballero, A.E., Williams, S., Pickering, E.J., and Prangnell, P.B., The Potential for Grain Refinement of Wire-Arc Additive Manufactured (WAAM) Ti-6Al-4V by ZrN and TiN Inoculation, Addit. Manuf., 2021, vol. 40, p. 101928. https://doi.org/10.1016/j.addma.2021.101928

Kalashnikov, K.N. and Sokolov, P.S., The Effect of Electron Beam Additive Manufacturing Parameters on the Grain Size and Tensile Properties of the Ti-4Al-3V Alloy, AIP Conf. Proc., 2020, vol. 2310, pp. 5–9. https://doi.org/10.1063/5.0034119

Dobromyslov, A.V. and Kazantseva, N.V., Phase Transformations in the Ti–Cu System, Phys. Met. Metallograph., 2000, vol. 89, pp. 467–473.

Obasi, G.C., Birosca, S., da Fonseca, J.Q., and Preuss, M., Effect of β Grain Growth on Variant Selection and Texture Memory Effect during α → β → α Phase Transformation in Ti-6Al-4V, Acta Mater., 2012, vol. 60(3), pp. 1048–1058. https://doi.org/10.1016/j.actamat.2011.10.038

Mei, W., Sun, J., and Wen, Y., Martensitic Transformation from β to α′ and α″ Phases in Ti–V Alloys: A First-Principles Study, J. Mater. Res., 2017, vol. 32, pp. 3183–3190. https://doi.org/10.1557/jmr.2017.276

Hunt, J.D., Steady State Columnar and Equiaxed Growth of Dendrites and Eutectic, Mater. Sci. Eng., 1984, vol. 65(1), pp. 75–83. https://doi.org/10.1016/0025-5416(84)90201-5

Bermingham, M.J., Kent, D., Zhan, H., StJohn, D.H., and Dargusch, M.S., Controlling the Microstructure and Properties of Wire Arc Additive Manufactured Ti-6Al-4V with Trace Boron Additions, Acta Mater., 2015, vol. 91, pp. 289–303. https://doi.org/10.1016/j.actamat.2015.03.035

Bermingham, M.J., McDonald, S.D., StJohn, D.H., and Dargusch, M.S., Beryllium as a Grain Refiner in Titanium Alloys, J. Alloys Compnd., 2009, vol. 481(1–2), pp. L20–L23. https://doi.org/10.1016/j.jallcom.2009.03.016

Funding

The work was carried out within the Government Statement of Work for ISPMS SB RAS, research line FWRW-2021-0012. The EBSD maps were studied within the RF President grant for state support of leading scientific schools NSh-1174.2022.4. The studies were carried out using the equipment of the Nanotech CUC (ISPMS SB RAS, Tomsk).

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated from Fizicheskaya Mezomekhanika, 2022, Vol. 25, No. 6, pp. 5–25.

Rights and permissions

About this article

Cite this article

Zykova, A.P., Nikolaeva, A.V., Vorontsov, A.V. et al. Effect of Copper Content on Grain Structure Evolution in Additively Manufactured Ti-6Al-4V Alloy. Phys Mesomech 26, 107–125 (2023). https://doi.org/10.1134/S1029959923020017

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S1029959923020017