Abstract

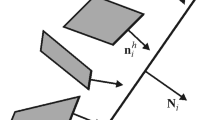

Multilevel modeling of structural evolution in polycrystals, which determines the macroscopic material properties, is currently one of the central research problems. The defect and grain/subgrain structure of polycrystalline materials changes greatly during thermomechanical processing. The grain structure is significantly affected by recrystallization, which leads to the formation of slightly defective recrystallization nuclei and their subsequent growth due to the absorption of more defective neighboring grains. This paper is aimed to develop a mathematical model for describing the behavior of polycrystalline materials during plastic deformation and subsequent heating to recrystallization temperatures. The main task is to describe grain structure evolution in polycrystals during this process. The considered recrystallization mechanism is based on the displacement of original grain boundary segments. As a result of preliminary cold plastic deformation, energy accumulates at defects (primarily dislocations) in neighboring grains. The energy difference between neighboring grains is the main driving force of grain boundary migration. When the recrystallized grain grows, the extent of the new high-angle boundary increases; the amount of energy expended for the boundary formation must be smaller than the decrease in the stored energy due to defect elimination. The subgrains adjacent to the grain boundary are the recrystallization nuclei in the considered deformation mechanism. They start to grow into the more defective grain when the Bailey-Hirsch criterion is satisfied. This study deals with polycrystalline materials with low stacking fault energy for which the effect of heating on the subgrain structure is insignificant. The energy stored in grains and subgrains is calculated using a two-level statistical model that considers individual grains and subgrains. Plastic deformation is assumed to occur through edge dislocation glide. A method is proposed for isolating flat boundary regions (facets) of new (recrystallized) grains, based on minimizing the grain boundary energy in the vicinity of the new boundary. This approach describes some experimentally observed recrystallization effects, such as the elongation of recrystallized grains in the initial recrystallization direction and the appearance of grain boundary facets that allow for boundary mobility.

Similar content being viewed by others

References

Zaafarani, N., Raabe, D., Singh, R.N., Roters, F., and Zaefferer, S., Three-Dimensional Investigation of the Texture and Microstructure below a Nanoindent in a Cu Single Crystal Using 3D EBSD and Crystal Plasticity Finite Element Simulations, Acta Mater., 2006, vol. 54, no. 7, pp. 1863–1876.

Schuren, J.C., Shade, P.A., Bernier, J.V., Shiu, F.L., Blank, B., Lind, J., Kenesei, P., Lienert, U., Suter, R.M., Turner, T.J., Dimiduk, D.M., and Alme, J., New Opportunities for Quantitative Tracking of Polycrystal Responses in Three Dimensions, Current Opinion Solid State Mater. Sci., 2015, vol. 19, no. 4, pp. 235–244.

Thompson, C.V., Structure Evolution during Processing of Polycrystalline Films, Ann. Rev. Mater. Sci., 2000, vol. 30, no. 1, pp. 159–190.

Valiev, R.Z. and Langdon, T.G., Principles of Equal-Channel Angular Pressing as a Processing Tool for Grain Refinement, Prog. Mater. Sci., 2006, vol. 51, no. 7, pp. 881–981.

Zhilyaev, A.P. and Langdon, T.G., Using High-Pressure Torsion for Metal Processing: Fundamentals and Applications, Prog. Mater. Sci., 2008, vol. 53, no. 6, pp. 893–979.

Azushima, A., Kopp, R., Korhonen, A., Yang, D.Y., Micari, F., Lahoti, G.D., Groche, P., Yanagimoto, J., Tsuji, N., Rosochowski, A., and Yanagida, A., Severe Plastic Deformation (SPD) Processes for Metals, CIRP Ann. Manuf. Technol., 2008, vol. 57, no. 2, pp. 716–735.

Storozhev, M.V. and Popov, E.A., Theory of Metal Forming, Moscow: Mashinostroyeniye, 1977.

Kaibyshev, O.A., Superplasticity of Commercial Alloys, Moscow: Metallurgiya, 1984.

Lakhtin, Yu.M., Engineering Physical Metallurgy and Heat-Treatment, Moscow: Mir Publishers, 1979.

Rollett, A., Humphreys, F.J., Rohrer, G.S., and Hatherly, M., Recrystallization and Related Annealing Phenomena, Oxford: Elsevier, 2004.

Gorelik, S.S., Dobatkin, S.V., and Kaputkina, L.M., Recrystallization of Metals and Alloys, Moscow: MISIS, 2005.

Biront, V.S., Theory of Heat Treatment of Metals, Krasnoyarsk: ITsMiZ, 2007.

Lakhtin, Yu.M. and Leontyeva, V.P., Materials Science and Engineering, Moscow: Mashinostroyeniye, 1980.

Trusov, P.V. and Kondratev, N.S., Nucleation Recrystallization Mechanisms in Metals at Thermomechanical Processing, PNRPUMech. Bull., 2016, no. 4, pp. 151–174. doi https://doi.org/10.15593/perm.mech/2016.4.09

Beck, P.A. and Sperry, P.R., Strain Induced Grain Boundary Migration in High Purity Aluminum, J. Appl. Phys., 1950, vol. 21, no. 2, pp. 150–152.

Kronberg, M.L. and Wilson, F.H., Secondary Recrystallization in Copper, Metals Trans., 1949, vol. 185, pp. 501–514.

Aust, K.T. and Rutter, J.W., Grain Boundary Migration in High-Purity Lead and Dilute Lead-Tin Alloys, Trans. Am. Inst. Mining Metallurg. Eng., 1959, vol. 215, no. 1, pp. 119–127.

Gottstein, G. and Shvindlerman, L.S., On the Orientation Dependence of Grain Boundary Migration, Scripta Metallurg. Mater., 1992, vol. 27, no. 11, pp. 1515–1520.

Miodownik, M.A., A Review of Microstructural Computer Models Used to Simulate Grain Growth and Recrystallisation in Aluminium Alloys, J. Light Met., 2002, vol. 2, no. 3, pp. 125–135.

Tan, K., Li, J., Guan, Z., Yang, J., and Shu, J., The Identification of Dynamic Recrystallization and Constitutive Modeling during Hot Deformation of Ti55511 Titanium Alloy, Mater. Design, 2015, vol. 84, pp. 204–211.

Quan, G.Z., Luo, G.C., Liang, J.T., Wu, D.S., Mao, A., and Liu, Q., Modelling for the Dynamic Recrystallization Evolution of Ti-6Al-4V Alloy in Two-Phase Temperature Range and a Wide Strain Rate Range, Comput. Mater. Sci., 2015, vol. 97, pp. 136–147.

Pan, Z., Liang, S.Y., Garmestani, H., and Shih, D.S., Prediction of Machining-Induced Phase Transformation and Grain Growth of Ti-6Al-4 V Alloy, Int. J. Adv. Manuf. Technol., 2016, vol. 87, no. 1–4, pp. 859–866.

Mahin, K.W., Hanson, K., and Morris, J.W., Comparative Analysis of the Cellular and Johnson-Mehl Microstructures through Computer Simulation, Acta Metallurg., 1980, vol. 28, no. 4, pp. 443–453.

Vandermeer, R.A. and Rath, B.B., Modeling Recrystallization Kinetics in a Deformed Iron Single Crystal, Metallurg. Trans. A, 1989, vol. 20, no. 3, pp. 391–401.

Vandermeer, R.A. and Jensen, D.J., Microstructural Path and Temperature Dependence of Recrystallization in Commercial Aluminum, Acta Mater., 2001, vol. 49, no. 11, pp. 2083–2094.

Lin, F., Zhang, Y., Tao, N., Pantleon, W., and Jensen, D.J., Effects of Heterogeneity on Recrystallization Kinetics of Nanocrystalline Copper Prepared by Dynamic Plastic Deformation, Acta Mater., 2014, vol. 72, pp. 252–261.

Summers, P.T., Mouritz, A.P., Case, S.W., and Lattimer, B.Y., Microstructure-Based Modeling of Residual Yield Strength and Strain Hardening after Fire Exposure of Aluminum Alloy 5083-H116, Mater. Sci. Eng. A, 2015, vol. 632, pp. 14–28.

Raabe, D., Cellular Automata in Materials Science with Particular Reference to Recrystallization Simulation, Ann. Rev. Mater. Res., 2002, vol. 32, no. 1, pp. 53–76.

Janssens, K.G.F., Random Grid, Three-Dimensional, Space-Time Coupled Cellular Automata for the Simulation of Recrystallization and Grain Growth, Model. Simul. Mater. Sci. Eng., 2003, vol. 11, no. 2, pp. 157–171.

Kugler, G. and Turk, R., Study of the Influence of Initial Microstructure Topology on the Kinetics of Static Recrystallization Using a Cellular Automata Model, Comput. Mater. Sci., 2006, vol. 37, no. 3, pp. 284–291.

Liu, Z., Olivares, R.O., Lei, Y., Garcia, C.I., and Wang, G., Microstructural Characterization and Recrystallization Kinetics Modeling of Annealing Cold-Rolled Vanadium Microalloyed HSLA Steels, J. Alloy. Compound., 2016, vol. 679, pp. 293–301.

Mellbin, Y., Hallberg, H., and Ristinmaa, M., A Combined Crystal Plasticity and Graph-Based Vertex Model of Dynamic Recrystallization at Large Deformations, Model. Simul. Mater. Sci. Eng., 2015, vol. 23, no. 4, p. 045011. doi https://doi.org/10.1088/0965-0393/23/4/045011

Chen, L.Q., A Novel Computer Simulation Technique for Modeling Grain Growth, Scripta Metallurg. Mater., 1995, vol. 32, no. 1, pp. 115–120.

Chen, L., Chen, J., Lebensohn, R.A., Ji, Y.Z., Heo, T.W., Bhattacharyya, S., Chang, K., Mathaudhu, S., Liu, Z.K., and Chen, L.Q., An Integrated Fast Fourier Transform-Based Phase-Field and Crystal Plasticity Approach to Model Recrystallization of Three Dimensional Polycrystals, Comp. Meth. Appl. Mech. Eng., 2015, vol. 285, pp. 829–848.

Zhao, H.K., Chan, T., Merriman, B., and Osher, S., A Variational Level Set Approach to Multiphase Motion, J. Comput. Phys., 1996, vol. 127, no. 1, pp. 179–195.

Bernacki, M., Chastel, Y., Coupez, T., and Loge, R.E., Level Set Framework for the Numerical Modelling of Primary Recrystallization in Polycrystalline Materials, Scripta Mater., 2008, vol. 58, no. 12, pp. 1129–1132.

Bernacki, M., Resk, H., Coupez, T., and Loge, R.E., Finite Element Model of Primary Recrystallization in Polycrystalline Aggregates Using a Level Set Framework, Model. Simul. Mater. Sci. Eng., 2009, vol. 17, no. 6, p. 064006.

Hallberg, H., A Modified Level Set Approach to 2D Modeling of Dynamic Recrystallization, Model. Simul. Mater. Sci. Eng., 2013, vol. 21, no. 8, pp. 085012.

Scholtes, B., Shakoor, M., Bozzolo, N., Bouchard, P.O., Settefrati, A., and Bernacki, M., Advances in Level-Set Modeling of Recrystallization at the Polycrystal Scale—Development of the Digi-µ Software, Key Eng. Mater. Trans. Tech. Publ., 2015, vol. 651, pp. 617–623.

Rollett, A.D., Overview of Modeling and Simulation of Recrystallization, Prog. Mater. Sci., 1997, vol. 42, no. 1–4, pp. 79–99.

Raabe, D. and Becker, R.C., Coupling of a Crystal Plasticity Finite-Element Model with a Probabilistic Cellular Automaton for Simulating Primary Static Recrystallization in Aluminium, Model. Simul. Mater. Sci. Eng., 2000, vol. 8, no. 4, pp. 445–462.

Andrietti, S., Chenot, J.L., Bernacki, M., Bouchard, P.O., Fourment, L., Hachem, E., and Perchat, E., Recent and Future Developments in Finite Element Metal Forming Simulation, Comp. Meth. Mater. Sci., 2015, vol. 15, no. 2, pp. 265–293.

Asaro, R.J., Crystal Plasticity, J. Appl. Mech. B, 1983, vol. 50, no. 4, pp. 921–934.

Roters, F., Eisenlohr, P., Hantcherli, L., Tjahjanto, D.D., Bieler, T.R., and Raabe, D., Overview of Constitutive Laws, Kinematics, Homogenization and Multiscale Methods in Crystal Plasticity Finite-Element Modeling: Theory, Experiments, Applications, Acta Mater., 2010, vol. 58, no. 4, pp. 1152–1211.

Trusov, P.V., Volegov, P.S., and Kondratyev, N.S., Crystal Plasticity Theories, Perm: Izd-vo PNIPU, 2013.

Trusov, P.V. and Shveykin, A.I., Multilevel Crystal Plasticity Models of Single- and Polycrystals. Statistical Models, Phys. Mesomech., 2013, vol. 16, no. 1, pp. 23–33.

Trusov, P.V., Sharifullina, E.R., and Shveykin, A.I., Three-Level Modeling of FCC Polycrystalline Inelastic Deformation: Grain Boundary Sliding Description, IOP Conf. Mater. Sci. Eng., 2015, vol. 71, p. 012081. doi https://doi.org/10.1088/1757-899X/71/1/012081

Trusov, P.V. and Shveykin, A.I., Multilevel Crystal Plasticity Models of Single- and Polycrystals. Direct Models, Phys. Mesomech., 2013, vol. 16, no. 2, pp. 99–124.

Trusov, P.V. and Shveykin, A.I., On Motion Decomposition and Constitutive Relations in Geometrically Nonlinear Elastoviscoplasticity of Crystallites, Phys. Mesomech., 2017, vol. 20, no. 4, pp. 377–391.

Lee, E.H., Elastic Plastic Deformation at Finite Strain, ASME J. Appl. Mech., 1969, vol. 36, pp. 1–6.

Shveikin, A.I. and Trusov, P.V., Correlation between Geometrically Nonlinear Elastoviscoplastic Constitutive Relations Formulated in Terms of the Actual and Unloaded Configurations for Crystallites, Phys. Mesomech., 2018, vol. 21, no. 3, pp. 193–202.

Trusov, P.V., Shveikin, A.I., and Yanz, A.Yu., Motion Decomposition, Frame-Indifferent Derivatives, and Constitutive Relations at Large Displacement Gradients from the Viewpoint of Multilevel Modeling, Phys. Mesomech., 2017, vol. 20, no. 4, pp. 357–376.

Rosakis, P., Rosakis, A.J., Ravichandran, G., and Hodowany, J., A Thermodynamic Internal Variable Model for the Partition of Plastic Work into Heat and Stored Energy in Metals, J. Mech. Phys. Solids, 2000, vol. 48, no. 3, pp. 581–607.

Sedov, L.I., A Course in Continuum Mechanics, Groningen: Wolters-Noordhoff, 1971.

Honeycombe, R.W.K., The Plastic Deformation of Metals, London-Baltimore: E. Arnold, 1984.

Titchener, A.L. and Bever, M.B., The Stored Energy of Cold Work, Prog. Met. Phys., 1958, vol. 7, pp. 247–338.

Plekhov, O.A., Structural and Kinetic Mechanisms of Deformation and Fracture of Coarse-Grained and Submicrocrystalline Materials, Doct. Degree Thesis (Phys. & Math.), Perm: IMSS UrO RAN, 2009.

Bellier, S.P. and Doherty, R.D., The Structure of Deformed Aluminium and Its Recrystallization—Investigations with Transmission Kossel Diffraction, Acta Metallurg., 1977, vol. 25, no. 5, pp. 521–538.

Williamson, G.K. and Smallman, R.E., III. Dislocation Densities in Some Annealed and Cold-Worked Metals from Measurements on the X-Ray Debye-Scherrer Spectrum, Philos. Mag., 1956, vol. 1, no. 1, pp. 34–46.

Cahn, R.W., A New Theory of Recrystallization Nuclei, Proc. Phys. Soc. Lond., 1950, vol. 63, pp. 323–336.

Bailey, J.E. and Hirsch, P.B., The Recrystallization Process in Some Polycrystalline Metals, Proc. Roy. Soc. Lond. A. Math. Phys. Eng. Sci., 1962, vol. 267, no. 1328, pp. 11–30.

Kondratev, N.S. and Trusov, P.V., Calculation of the Intergranular Energy in Two-Level Physical Models for Describing Thermomechanical Processing of Polycrystals with Account for Discontinuous Dynamic Recrystallization, Nanomech. Sci. Technol. Int. J., 2016, vol. 7, pp. 107–122.

Kozlov, E.V., Trishkina, L.I., Popova, N.A., and Koneva, N.A., Dislocation Physics in the Multilevel Approach to Plastic Deformation, Phys. Mesomech., 2011, vol. 14, no. 5–6, pp. 283–296.

Trusov, P.V. and Kondratev, N.S., Description of Inelastic Deformation of Two-Phase Polycrystalline Materials, Deform. Razrush. Mater., 2013, no. 6, pp. 8–15.

Burke, J.E. and Turnbull, D., Recrystallization and Grain Growth, Prog. Met. Phys., 1952, vol. 3, pp. 220–244.

Kondratev, N.S., Trusov, P.V., and Bazhenov, V.G., Influence of Grains Orientation on the Migration Velocity of High-Angle Boundaries, Nanomech. Sci. Technol. Int. J., 2017, vol. 8, pp. 243–259.

Rae, C.M.F. and Smith, D.A., On the Mechanisms of Grain Boundary Migration, Philos. Mag. A, 1980, vol. 41, no. 4, pp. 477–492.

Kondratev, N.S. and Trusov, P.V., Disorientation Measure of Neighboring Crystallites Slip Systems in a Polycrystalline Aggregate, PNRPU Mech Bull., 2012, no. 2, pp. 112–127.

Kondratev, N.S. and Trusov, P.V., Description of Hardening Slip Systems due to the Boundaries of the Crystallines in a Polycrystalline Aggregate, PNRPU Mech. Bull., 2012, no. 3, pp. 78–97.

Rybin, V.V., High Plastic Strains and Fracture of Metals, Moscow: Metallurgiya, 1986.

Hurley, P.J. and Humphreys, F.J., The Application of EBSD to the Study of Substructural Development in a Cold Rolled Single-Phase Aluminium Alloy, Acta Mater., 2003, vol. 51, no. 4, pp. 1087–1102.

Theyssier, M.C. and Driver, J.H., Recrystallization Nucleation Mechanism along Boundaries in Hot Deformed Al Bicrystals, Mater Sci. Eng. A, 1999, vol. 272, no. 1, pp. 73–82.

Author information

Authors and Affiliations

Corresponding author

Additional information

Russian Text © The Author(s), 2018, published in Fizicheskaya Mezomekhanika, 2018, Vol. 21, No. 2, pp. 21–32.

Funding

The work was carried out with the financial support of RFBR in the framework of research project No. 16-31-60002 mol_a_dk, and the RF Ministry of Education and Science (the basic part of the state task for PNRPU, No. 9.7434.2017/8.9).

Rights and permissions

About this article

Cite this article

Trusov, P.V., Kondratyev, N.S. Two-Level Elastoviscoplastic Model: An Application to the Analysis of Grain Structure Evolution under Static Recrystallization. Phys Mesomech 22, 230–241 (2019). https://doi.org/10.1134/S1029959919030081

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S1029959919030081