Abstract

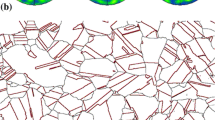

The mechanical properties and fracture of a TiNi alloy (Ti-55.8 wt % Ni) have been investigated under vacuum heat treatment at 700–1200°C. Three-point bending and low cycle fatigue tests were conducted on heat treated wire samples under extreme loading conditions (large strains and alternating bending loads) to determine the effect of the annealing temperature on the superelastic behavior of the alloy. It was found that an increase in the heat treatment temperature leads to grain coarsening in the alloy, but the coarsening effect on its superelastic behavior is insignificant at low bending strains (4.0–4.5%). With heat treatment temperature variation from 700 to 1200°C, the shape of the alloy stress-strain curves remains almost unchanged for all bended samples, but with increasing heat treatment temperature the martensitic shear stress and residual strain slightly increase. In low cycle bending tests, the alloy ductility reduces significantly after heat treatment above 1100°C. Fractographic analysis of the tested alloy samples revealed different fracture surface structures depending on the heat treatment conditions, but the same fracture mechanism. In all cases, fracture occurs by quasi-cleavage, and the microcrack nucleus is associated with Ti2Ni/Ti4Ni2O inclusion particles or surface defects. The general results indicate the possibility of diffusion welding of TiNi alloys at a temperature of 1000–1100°C, without pronounced changes in their mechanical properties and ductility.

Similar content being viewed by others

References

Shape Memory Alloys: Fundamentals, Modeling and Applications, Brailovski, V., Prokoshkin, S., Terriault, P., and Trochu, F., Eds., Montreal: ETS Publ., 2003.

Pushin, V.G., Alloys with a Thermomechanical Memory: Structure, Properties, and Application, Phys. Met. Metallogr., 2000, vol. 90 (suppl. 1), pp. S68–S95.

Jani, J.M., Leary, M., Subic, A., and Gibson, M.A., A Review of Shape Memory Alloy Research, Applications and Opportunities, Mater. Design, 2014, vol. 56, pp. 1078–1113.

Haas, T. and Schuessler, A., Welding and Joining of TiNi Shape Memory Alloys: Engineering Aspects and Medical Applications, in SMST-99: Proc. 1st Int. Euro. Conf. on Shape Memory and Superelastic Technologies, Antwerpen, Belguim, 1999, pp. 103–114.

Shlyapin, S.D., Gusev, D.E., Senkevich, K.S., and Mamaev, V.S., Structure and Properties of Welded Joints of TiNi Alloys, Tekhnol. Legk. Splavov, 2008, no. 3, pp. 65–72.

Oliveira, J.P., Miranda, R.M., and Braz Fernandes, F.M., Welding and Joining of NiTi Shape Memory Alloys: A Review, Progr. Mater. Sci., 2017, vol. 88, pp. 412–466.

Senkevich, K.S. and Shlyapin, S.D., Investigation of the Process of Diffusion Bonding of Alloys Based on Titanium Nickelide, Welding Int., 2012, vol. 26, pp. 736–738.

Senkevich, K.S., A Study of the Microstructure of Diffusion Joints of TiNi-Base Alloys, Met. Sci. Heat Treat., 2014, vol. 55, no. 11–12, pp. 675–679.

Gusev, D.E., Senkevich, K.S., and Knyazev, M.I., Effect of High-Temperature Treatment on the Structure and Properties of TiNi-Base Alloys, Met. Sci. Heat Treat., 2012, vol. 54, no. 3–4, pp. 184–188.

Senkevich, K.S. and Gusev, D.E., Study of Alloy Microstructure Based on TiNi after High-Temperature Treatment, Met. Sci. Heat Treat., 2016, vol. 58, no. 5–6, pp. 273–278.

Otsuka, K. and Ren, X., Physical Metallurgy of Ti-Ni-Based Shape Memory Alloys, Progr. Mater. Sci., 2005, vol. 50, pp. 511–678.

Kollerov, M.Yu., Il’in, AA, Gusev, D.E., and Lamzin, D.A., Effect of Deformation Mechanisms on the Fatigue Properties of Metallic Materials, Russ. Metallurgy, 2008, vol. 2008, no. 5, pp. 419–424.

Wang, X., Xu, B., Yue, Z., and Tong, X., Fracture Behavior of the Compact Tension Specimens in NiTi Shape Memory Alloys, Mater. Sci. Eng. A, 2008, vol. 485(1–2), pp. 14–19.

Gall, K., Yang, N., Sehitoglu, H., and Chumlyakov, Y.I., Fracture of Precipitated NiTi Shape Memory Alloys, Int. J. Fract., 2001, vol. 109(2), pp. 189–207.

Olsen, J.S., Zhang, Z.L., Lu, H., and Van der Eijk, C., Fracture of Notched Round-Bar NiTi-Specimens, Eng. Fract. Mech., 2012, vol. 84, pp. 1–14.

Rahim, M., Frenzel, J., Frotscher, M., Pfetzing-Micklich, J., Steegmuller, R., Wohlschlogel, M., Mughrabi, H., and Eggeler, G., Impurity Levels and Fatigue Lives of Pseudoelastic NiTi Shape Memory Alloys, Acta Mater., 2013, vol. 61, pp. 3667–3686.

Gloanec, A.-L., Cerracchio, P., Reynier, B., Van Herpen, A., and Riberty, P., Fatigue Crack Initiation and Propagation of a TiNi Shape Memory Alloy, Scripta Mater., 2010, vol. 62(10), pp. 786–789.

Joshi, V.A., Titanium Alloys: An Atlas of Structures and Fracture Features, London: Taylor & Francis Group CRC Press, 2006.

Author information

Authors and Affiliations

Corresponding author

Additional information

Russian Text © The Author(s), 2017, published in Fizicheskaya Mezomekhanika, 2017, Vol. 20, No. 6, pp. 105–111.

Rights and permissions

About this article

Cite this article

Senkevich, K.S., Gusev, D.E. Effect of Heat Treatment on the Mechanical Behavior and Fracture of TiNi Alloy. Phys Mesomech 22, 224–229 (2019). https://doi.org/10.1134/S102995991903007X

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S102995991903007X