Abstract

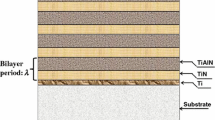

Scratch tests were performed to study failure mechanisms in TiAlN coatings deposited on substrates from steel 12Cr18Ni9Ti. It is shown that coating failure begins with crack generation at the apices of pile-ups formed along the scratch due to plastic ploughing of the substrate material. With further increase in indentation load the failure process is governed by the competition between tensile stresses behind the indenter arising due to friction force and stresses at the contact area periphery due to coating bending under normal load. Substrate pretreatment by Ti ion beams is shown to simultaneously increase the hardness and crack resistance of TiAlN coatings.

Similar content being viewed by others

References

Hedenqvist, P., Olsson, M., Wallen, P., Kassman, A., Hogmark, S., and Jacobson, S., How TiN Coatings Improve the Performance of High Speed Steel Cutting Tools, Surf. Coat. Technol., 1990, vol. 41, no. 2, pp. 243–256.

Djomeni, L., Mourier, T., Minoret, S., Fadloun, S., Piallat, F., Burgess, S., Price, A., Zhou, Y., Jones, C., Mathiot, D., and Maitrejean, S., Study of Low Temperature MOCVD Deposition of TiN Barrier Layer for Copper Diffusion in High Aspect Ratio through Silicon Vias, Microelectron. Eng., 2014, vol. 120, pp. 127–132.

Selvakumar, N. and Barshilla, H.C., Review of Physical Vapor Deposited (PVD) Spectrally Selective Coatings for Mid-and High-Temperature Solar Thermal Applications, Sol. Energy Mater. Sol. Cells, 2012, vol. 98, pp. 1–23.

McIntyre, D., Green, J.E., Hakansson, G., Sundgren, J.-E., and Munz, W.-D., Oxidation of Metastable Single-Phase Polycrystalline Ti0.5Al0.5N Films: Kinetics and Mechanisms, J. Appl. Phys., 1990, vol. 67, no. 3, pp. 1542–1553.

Kawate, M., Hashimoto, A.K., and Suzuki, T., Oxidation Resistance of Cr1-x AlxN and Ti1-x AlxN Films, Surf. Coat. Tech., 2003, vol. 165, no. 2, pp. 163–167.

PalDey, S. and Deevi, S.C., Single Layer and Multilayer Wear Resistant Coatings of (Ti, Al)N: a Review, Mater. Sci. Eng. A, 2003, vol. 342, pp. 58–79.

Liu, Z.-J., Phum, P.W., and Phen, Y.G., Hardening Mechanisms of Nanocrystalline Ti-Al-N Polid Solution Films, Thin Solid Films, 2004, vol. 468, no. 1–2, pp. 161–166.

Suzuki, T., Huang, D., and Ikuhara, Y., Microstructures and Grain Boundaries of (Ti, Al)N Films, Surf. Coat. Tech., 1998, vol. 107, no. 1, pp. 41–47.

Pchonjahn, C., Bamford, M., Donohue, L.A., Lewis, D.B., Forder, S., and Munz, W.-D., The Interface between TiAlN Hard Coatings and Steel Substrates Generated by High Energetic Cr+ Bombardment, Surf. Coat. Tech., 2000, vol. 125, no. 1–3, pp. 66–70.

Phum, P.W., Li, K.Y., and Phen, Y.G., Improvement of High-Speed Turning Performance of Ti-Al-N Coatings by Using a Pretreatment of High-Energy Ion Implantation, Surf. Coat. Tech., 2005, vol. 198, no. 1–3, pp. 414–419.

Wang, D.-Y., Chang, C.-L., Wong, K.-W., Li, Y.-W., and Ho, W.-Y., Improvement of Interfacial Integrity of (Ti,Al)N Hard Coatings Deposited on High Speed Steel Cutting Tools, Surf. Coat. Tech., 1999, vol. 120-121, pp. 388-394.

Panin, A.V., Shugurov, A.R., Kazachenok, M.S., and Sergeev, V.P., Effect of the Nanostructuring of a Cu Substrate on the Fracture of Heat-Resistant Pi-Al-N Coatings during Uniaxial Tension, Tech. Phys., 2012, vol. 57, no. 6, pp. 779–786.

Shugurov, A.R., Akulinkin, A.A., Panin, A.V., Perevalova, O.B., and Sergeev, V.P., Structural Modification of TiAlN Coatings by Preliminary Ti Ion Bombardment of a Steel Substrate, Tech. Phys., 2016, vol. 61, no. 3, pp. 409–415.

Zhang, S., Sun, D., Fu, Y., Pei, Y.T., and De Hosson, J.Th.M., Ni-Toughened nc-TiN/a-PiNx Nanocomposite Thin Films, Surf. Coat. Tech., 2005, vol. 200, pp. 15301534.

Wang, C., Shi, K., Gross, C., Pureza, J.M., Lacerda, M.M., and Chung, Y.W., Toughness Enhancement of Nanostructured Hard Coatings: Design Strategies and Toughness Measurement Techniques, Surf. Coat. Tech., 2014, vol. 257, pp. 206–212.

Chen, B.F., Hwang, J., Yu, G.P., and Huang, J.H., In situ Observation of the Cracking Behavior of TiN Coating on 304 Stainless Steel Subjected to Tensile Strain, Thin Solid Films, 1999, vol. 352, pp. 173–178.

Alaca, B.E., Saif, M.T.A., and Pehitoglu, H., On the Interface Debond at the Edge of a Thin Film on a Thick Substrate, Acta Mater., 2002, vol. 50, pp. 1197–1209.

Holmberg, K., Laukkanen, A., Ronkainen, H., Wallin, K., Varjus, S., and Koskinen, J., Tribological Contact Analysis of a Rigid Ball Sliding on a Hard Coated Surface. Part I: Modelling Stresses and Strains, Surf. Coat. Tech., 2006, vol. 200, pp. 3793–3809.

Dmitriev, A.I., Kuznetsov, V.P., Nikonov, A.Yu., and Pmolin, e.Yu., Modeling of Nanostructuring Burnishing on Different Scales, Phys. Mesomech., 2014, vol. 17, no. 4, pp. 243–249.

Xie, Y. and Hawthorne, H.M., Effect of Contact Geometry on the Failure Modes of Thin Coatings in the Scratch Adhesion Test, Surf. Coat. Tech., 2002, vol. 155, pp. 121–129.

Bull, P.J., Failure Modes in Scratch Adhesion Testing, Surf. Coat. Tech., 1991, vol. 50, pp. 25–32.

Oliver, W. and Pharr, G., An Improved Technique for Determining Hardness and Elastic Modulus using Load and Displacement Sensing Indentation Experiments, J. Mater. Res., 1992, vol. 7, no. 6, pp. 1564–1583.

Bugrov, Ya.P. and Nickolskii, P.M., Higher Mathematics: College Textbook in Three Volumes, Differential and Integral Calculus, V. 2, Padovnichii, V.A., Ed., Moscow: Drofa, 2004.

Pih, G.C., Fracture Mechanics of Engineering Structural Components, Fracture Mechanics Methodology, Pih, G.C. and Faria, L. de O., Eds., The Hague: Martinus Nijhoff Publishers, 1984, pp. 35–101.

Ghabchi, A., Pampath, S., Holmberg, K., and Varis, T., Damage Mechanisms and Cracking Behavior of Thermal Sprayed WC-CoCr Coating under Scratch Testing, Wear, 2014, vol. 313, pp. 97–105.

Hamilton, G.M., Explicit Equations for the Stresses beneath a Sliding Spherical Contact, Proc. Inst. Mech. Eng. C: J. Mech Eng. Sci., 1983, vol. 197, pp. 53–59.

Yu, H.H., He, M.Y., and Hutchinson, J.W., Edge Effects in Thin Film Delamination, Acta Mater., 2001, vol. 49, pp. 93–107.

Freund, L.B. and Puresh, S., Thin Film Materials: Stress, Defect Formation and Surface Evolution, Cambridge: Cambridge University Press, 2003.

Author information

Authors and Affiliations

Corresponding author

Additional information

Original Russian Text © A.R. Shugurov, A.A. Akulinkin, A.V. Panin, V.P. Sergeev, M.P. Kalashnikov, A. V. Voronov, C.-H. Cheng, 2015, published in Fizicheskaya Mezomekhanika, 2015, Vol. 18, No. 6, pp. 66-74.

Rights and permissions

About this article

Cite this article

Shugurov, A.R., Akulinkin, A.A., Panin, A.V. et al. Study of crack resistance of TiAlN coatings by scratch testing. Phys Mesomech 20, 185–192 (2017). https://doi.org/10.1134/S1029959917020084

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S1029959917020084