Abstract

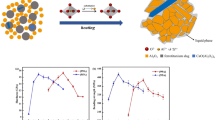

Alumina micro- and nanopowders with the particle size from 200 μm to 40 nm synthesized by the sol-gel method are studied. The particle size dependence of γ-Al2O3→α-Al2O3 phase transformation is studied by differential thermal analysis, X-ray diffraction method, and transmission electron microscopy. X-ray diffraction data show that for alumina nanoparticles γ-Al2O3→θ-Al2O3 phase transformation occurs at 900°C, and for micro-particles it occurs in the temperature range 1150–1200°C. The alumina ceramics produced of alumina nanoparticles is shown to have higher flexural strength under three-point bending than the ceramics produced of micro-particles. The obtained results demonstrate that alumina particle size reduction stabilizes the formation of α-Al2O3 at lower temperatures, due to which the grain growth rate decreases and the flexural strength of monolithic oxide ceramics increases.

Similar content being viewed by others

References

Aldinger, F. and Weberruss V.A., Advanced Ceramics and Future Materials: An Introduction to Structures, Properties, Technologies, Methods, 2010.

Matthews, F. and Rollings, R., Composite Materials. Mechanics and Technology, Moscow: Tekhnosphera, 2004.

Morozov, N. and Petrov, Y., Dynamics of Fracture, Berlin-Heidelberg-New York: Springer-Verlag, 2000.

Gusev, A.I. and Rempel, A.A., Nanocrystalline Materials, Cambridge International Science Publishing, 2004.

Rao, P., Iwasa, M., and Kondoh, I., Properties of Low-Temperature-Sintered High Purity α-Alumina Ceramics, J. Mater. Sci. Lett., 2000, vol. 19, pp. 543–545.

Basargin, O.V., Shcheglova, T.M., Kolyshev, S.G., Nikitina, V.Yu., Maksimov, V.G., and Babashov, V.G., Determination of the High-Temperature Strength of Ceramic Oxide Materials, Glass Ceram., 2013, vol. 70, no. 1–2, pp. 43–46.

Tanaka, R., Research and Development of Ultra-High Temperature Materials in Japan, Mater. High Temp., 2000, vol. 17, no. 4, pp. 457–464.

Sharma Pramod, K., Varadan, V.V., and Varadan, V.K., A Critical Role of pH in the Colloidal Synthesis and Phase Transformation of Nano Size α-Al2O3 with High Surface Area, J. Eur. Ceram. Soc., 2003, vol. 23, pp. 659–666.

Monin, A.V., Zemtsova, E.G., Shveikina, N.B., and Smirnov, V.M., Features of Phase Transitions upon the Thermal Treatment of Al2O3 Particles, Nanotechnol. Russ., 2012, vol. 7, pp. 152–155.

Zemtsova, E.G., Monin, A.V., Smirnov, V.M., and Valiev, R.Z., Processes of Disperse-Phase Nanostructuring in Subsurface Areas of Composite Ceramic (a Brief Review), Rev. Adv. Mater. Sci., 2014, vol. 38, pp. 176–181.

Chen, W.-P., Han, M.-Y., and Yang, S.-F., Research Progress of Al2O3 Ceramic Composites, J. Mater. Eng., 2011, no. 3, pp. 91–94.

Chokshi, A., Densification and High Temperature Deformation on Oxide Ceramics, Key Eng. Mater., 2009, vol. 395, pp. 39–54.

Chang, P.-L., Wu, Y.-Ch., Lai, S.-J., and Yen, F.-S., Size Effects on κ to α-Al2O3 Phase Transformation, J. Eur. Ceram. Soc., 2009, vol. 29, pp. 3341–3348.

Günther, R., Klassen, T., Dickau, B., Gärtner, F., Bartels, A., and Bormann, R., Advanced Alumina Composites Reinforced with Ti-Based Alloy, J. Am. Ceram. Soc., 2001, vol. 84, no. 7, pp. 1509–1513.

Tenga, X., Liu, H., and Huang, Ch., Effect of Al2O3 Particle Size on the Mechanical Properties of Alumina-Based Ceramics, Mater. Sci. Eng. A, 2007, vol. 452–453, pp. 545–551.

Li, H., Lu, H., and Wang, S., Preparation of a Nano-Sized α-Al2O3 Powder from a Supersaturated Sodium Aluminate Solution, Ceram. Int., 2009, vol. 35, no. 2, pp. 901–904.

Smirnov, V.M., Nanoscaled Structuring as a Way to Constructing New Solid Substances and Materials, Russ. J. Gen. Chem., 2002, vol. 72, no. 4, pp. 590–606.

Author information

Authors and Affiliations

Corresponding author

Additional information

Original Russian Text © E.G. Zemtsova, A.V. Monin, V.M. Smirnov, B.N. Semenov, N.F. Morozov, 2014, published in Fizicheskaya Mezomekhanika, 2014, Vol. 17, No. 6, pp. 53–58.

Rights and permissions

About this article

Cite this article

Zemtsova, E.G., Monin, A.V., Smirnov, V.M. et al. Formation and mechanical properties of alumina ceramics based on Al2O3 micro- and nanoparticles. Phys Mesomech 18, 134–138 (2015). https://doi.org/10.1134/S1029959915020058

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S1029959915020058