Abstract

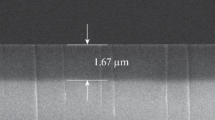

It is proposed to use “liquid glasses” of various compositions as substrates for space-based X-ray optical elements. One of the main requirements for such materials is the smallest weight and the possibility of surface treatment. Special requirements are imposed on the surface roughness, which should be less than 1 nm, and the shape accuracy should be at the level of a few nanometers. It is proposed to use a class of compounds based on alkali-metal silicates or strong organic bases as a material that makes it possible to form the required shape and surface roughness, as well as to provide subsequent processing. The effect of smoothing the surface roughness of liquid glass of three different compositions deposited onto chromium and nickel films is studied. The roughness of all surfaces before and after the deposition of structures is measured using an atomic force microscope. The roughness was calculated using the power spectral density function (PSD function). The structures deposited onto the surface were irradiated with accelerated argon ions with an energy of 800 eV. The etching depth and effective roughness were measured. One of the studied compositions shows a satisfactory reduction in the roughness and stability of this effect during ion etching.

Similar content being viewed by others

REFERENCES

M. Born and E. Wolf, Principles of Optics (Cambridge University Press, Cambridge, 1999).

N. I. Chkhalo, M. S. Mikhaylenko, A. V. Mil’kov, A. E. Pestov, V. N. Polkovnikov, N. N. Salashchenko, I. L. Strulya, M. V. Zorina, and S. Yu. Zuev, Proc. SPIE 10235, 102350 (2017). https://doi.org/10.1117/12.2269312

M. S. Mikhailenko, N. I. Chkhalo, A. E. Pestov, V. N. Polkovnikov, M. V. Zorina, S. Yu. Zuev, D. S. Kazakov, A. V. Milkov, I. L. Strulya, V. A. Filichkina, and A. S. Kozlov, Appl. Opt. 58, 3652 (2019).

M. S. Mikhailenko, M. V. Zorina, D. E. Pariev, A. E. Pestov, N. N. Salashchenko, I. L. Strulya, S. A. Churin, and N. I. Chkhalo, J. Surf. Invest.: X-ray, Synchrotron Neutron Tech. 11, 485 (2017). https://doi.org/10.1134/S102745101703017X

O. L. Figovskii and P. G. Kudryavtsev, Inzh. Vestn. Dona, No. 2 (29), 117 (2014).

V. I. Korneev and V. V. Danilov, Liquid and Soluble Glass (Stroiizdat, St. Petersburg, 1996) [in Russian].

N. I. Chkhalo, I. A. Kaskov, I. V. Malyshev, M. S. Mikhay-lenko, A. E. Pestov, V. N. Polkovnikov, N. N. Salashchenko, M. N. Toropov, and I. G. Zabrodin, Precis. Eng. 48, 338 (2017). https://doi.org/10.1016/j.precisioneng.2017.01.004

N. I. Chkhalo, N. N. Salashchenko, and M. V. Zorina, Rev. Sci. Instrum. 86, 016102 (2015). https://doi.org/10.1063/1.4905336

A. E. Shupenev, N. S. Pankova, I. S. Korshunov, and A. G. Grigor’yants, Izv. Vyssh. Uchebn. Zaved., Mashinostr. 4, 18 (2019). https://doi.org/10.18698/0536-1044-2019-4-18-27

Yu. M. Nikolaenko, A. S. Korneevets, N. B. Efros, V. V. Burkhovetskii, and I. Yu. Reshidova, Tech. Phys. Lett. 45, 679 (2019). https://doi.org/10.1134/S1063785019070083

A. P. Firstov, Liteishchik Ross., No. 7, 15 (2015).

A. P. Firstov, Evraz. Soyuz Uch., No. 10(67), 61 (2019). https://doi.org/10.31618/ESU.2413-9335.2019.6.67.417

N. E. Nikolaev and V. Yu. Miretskii, USSR Inventor’s Certificate No. 1377262, Byull. Izobret., No. 8 (1988).

V. B. Obukhova and G. N. Pesternikov, RF Patent No. 2683320, Byull. Izobret., No. 10 (2019).

A. N. Levichev, N. G. Pavlyukovich, M. M. Kaziev, and P. M. Valetskii, RF Patent No. 22999229, Byull. Izobret., No. 14 (2007).

H. H. W. Weldes, US Patent No. 3239549 (1966).

H. H. W. Weldes, US Patent No. 3383386 (1968).

P. C. Yates, US Patent No. 3630954 (1971).

H. H. W. Weldes, US Patent No. 3769309 (1973).

P. G. Kudryavtsev and O. L. Figovskii, Nanotekhnol. Stroit. 6 (6), 27 (2014). https://doi.org/10.15828/2075-8545-2014-6-6-27-45

Funding

The study was carried out as a part of state assignment no. 0030-2021-0022 with the use of equipment of the Center for Collective Use “Physics and Technologies of Microstructures and Nanostructures” at the Institute of Physics of Microstructures, Russian Academy of Sciences.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

The authors declare that they have no conflicts of interest.

Additional information

Translated by S. Rostovtseva

Rights and permissions

About this article

Cite this article

Mikhailenko, M.S., Zorina, M.V., Petrova, D.V. et al. Prospects for the Application of Liquid Glass for Smoothing the Surface of Optical Elements. J. Surf. Investig. 17, 1332–1337 (2023). https://doi.org/10.1134/S1027451023060368

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S1027451023060368