Abstract

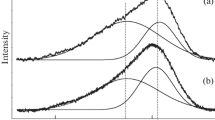

We study composite coatings based on amorphous carbon with encapsulated silver nanoparticles, synthesized by pulsed-plasma sputtering in an argon atmosphere. The deposition is assisted by 100–300 eV argon ions using a KLAN-53M source; samples without ion assistance are also prepared for comparison. Transmission electron microscopy, electron diffraction, and characteristic electron-energy-loss spectroscopy are used to analyze the effect of the ion-assistance parameters on silver nanoparticles and the properties of the carbon matrix. The maximum fraction of sp3-hybridized atoms in the amorphous carbon matrix is achieved at an assistance energy of 100 eV and a current density of 22 μA/cm2, which is due to material densification and the cross-linking of graphite layers by the ion beam at the specified parameters. The effect of ion-induced processes on the size distribution of silver nanoparticles is described. Ion assistance initiates several processes during deposition: defect formation promoting the formation of nucleation centers for particles 3–5 nm in size, surface diffusion enhancing the coalescence of adatoms and nuclei, and the selective sputtering of silver. The combination of these effects leads to the formation of silver particles of two characteristic sizes: 3–5 and 20–30 nm.

Similar content being viewed by others

REFERENCES

E.A. Belenkov and V. A. Greshnyakov, Phys. Solid State 55, 1754 (2013).

Y. Wang, H. Li, L. Ji, F. Zhao, Q. Kong, Y. Wang, X. Liu, W. Quan, H. Zhou, and J. Chen, Surf. Coat. Technol. 205, 3058 (2011). https://doi.org/10.1016/j.surfcoat.2010.11.019

A. Tibrewala, E. Peiner, R. Bandorf, S. Biehl, and H. Luthje, Appl. Surf. Sci. 252, 5387 (2006). https://doi.org/10.1016/j.apsusc.2005.12.046

D. Dasgupta, F. Demichelis, and A. Tagliaferro, Philos. Mag. B 63, 1255 (1991). https://doi.org/10.1080/13642819108205558

A. Gangopadhyay, Tribol. Lett. 5, 25 (1998). https://doi.org/10.1023/A:1019152515982

C. Popov, W. Kulisch, M. Jelinek, A. Bock, and J. Strnad, Thin Solid Films 494, 92 (2006). https://doi.org/10.1016/j.tsf.2005.07.163

P. Yang, J. Y. Chen, Y. X. Leng, H. Sun, N. Huang, and P. K. Chu, Surf. Coat. Technol. 186, 125 (2004). https://doi.org/10.1016/j.surfcoat.2004.04.039

L. A. Goncharov and V. G. Grigor’yan, Prikl. Fiz., No. 5, 67 (2007).

F. Rossi, B. Andre, A. Veen, P. E. Mijnarends, H. Schut, M. P. Delplancke, W. Gissler, J. Haupt, G. Lucazeau, and L. Abello, J. Appl. Phys. 75, 3121 (1998). https://doi.org/10.1063/1.356164

E. A. Buntov and A. F. Zatsepin, J. Phys. Chem. A 124, 9128 (2020). https://doi.org/10.1021/acs.jpca.0c05739

E. A. Buntov, A. F. Zatsepin, A. I. Slesarev, Yu. V. Shchapova, S. Challinger, and I. Baikie, Carbon 152, 388 (2019). https://doi.org/10.1016/j.carbon.2019.06.042

O. A. Streletskiy, I. A. Zavidovskiy, O. Yu. Nischak, and S. V. Dvoryak, Thin Solid Films 701, 137948 (2020). https://doi.org/10.1016/j.tsf.2020.137948

O. A. Streletskiy, I. A. Zavidovskiy, O. Yu. Nischak, and A. A. Haidarov, Vacuum 175, 109286 (2020). https://doi.org/10.1016/j.vacuum.2020.109286

M. Krause, A. Mücklich, T. W. H. Oates, M. Zschornak, S. Wintz, J. L. Endrino, C. Baehtz, A. Shalimov, S. Gemming, and G. Abrasonis, Appl. Phys. Lett. 101, 053112 (2012). https://doi.org/10.1063/1.4739417

I. A. Faĭzrakhmanov, V. V. Bazarov, A. L. Stepanov, and I. B. Khaĭbullin, Semiconductors 40, 414 (2006). https://doi.org/10.1134/S1063782606040087

A. Jurkevičiūtė, G. Klimaitė, T. Tamulevičius, J. Fiutowski, H.-G. Rubahn, and S. Tamulevičius, Adv. Engineering Mater. 22, 1900951 (2020). https://doi.org/10.1002/adem.201900951

S. Domínguez-Meister, T. C. Rojas, J. E. Frías, and J. C. Sánchez-López, Tribol. Int. 140, 105837 (2019). https://doi.org/10.1016/j.triboint.2019.06.030

L. Patnaik, S. R. Maity, and S. Kumar, Ceram. Int. 47, 6736 (2021). https://doi.org/10.1016/j.ceramint.2020.11.016

S. Yu. Krasnoborod’ko, V. M. Roshchin, M. V. Silibin, and, V. I. Shevyakov, Khim. Fiz. Mezoskop. 13, 444 (2011).

A. P. Alekhin, G. M. Boleiko, S. A. Gudkova, A. M. Markeev, A. A. Sigarev, V. F. Toknova, A. G. Kirilenko, R. V. Lapshin, E. N. Kozlov, and D. V. Tetyukhin, Nanotechnol. Russ. 5, 596 (2010).

A. I. Poplavsky, A. Ya. Kolpakov, Yu. Kudriavtsev, R. Asomoza, I. Yu. Goncharov, M. E. Galkina, S. S. Manokhin, and V. A. Kharchenko, Vacuum 152, 193 (2018). https://doi.org/10.1016/j.vacuum.2018.03.028

I. A. Zavidovskii, O. A. Streletskii, O. Yu. Nishchak, N. F. Savchenko, S. V. Dvoryak, and A. V. Pavlikov, Tech. Phys. 65, 468 (2020). https://doi.org/10.21883/JTF.2020.03.48937.232-19

A. Poplavsky, Yu. Kudriavtsev, and A. Kolpakov, Vacuum 184, 109919 (2021). https://doi.org/10.1016/j.vacuum.2020.109919

I. A. Zavidovskiy, O. A. Streletskiy, O. Yu. Nishchak, A. A. Haidarov, and A. V. Pavlikov, Thin Solid Films 738, 138966 (2021). https://doi.org/10.1016/j.tsf.2021.138966

Platar (2000). http://www.platar.ru/P6E.html. Cited 22 August 2021.

Intelligent Scientometric Case Study System (2011). https://istina.msu.ru/equipment/card/29156772. Cited 22 August 2021

N. Oudini, G. J. M. Hagelaar, J.-P. Boeuf, and L. Garrrigues, J. Appl. Phys. 109, 073310 (2011). https://doi.org/10.1063/1.3572053

T. Mori and Y. Namba, J. Appl. Phys. 55, 3276 (1984). https://doi.org/10.1063/1.333385

V. O. Babaev, Ju. V. Bykov, and M. B. Guseva, Thin Solid Films 38, 1 (1976). https://doi.org/10.1016/0040-6090(76)90272-8

A. Ya. Kolpakov, A. I. Poplavsky, S. S. Manokhin, M. E. Galkina, I. Yu. Goncharov, R. A. Liubushkin, J. V. Gerus, P. V. Turbin, and L. V. Malikov, J. Nano- Electron. Phys. 8, 04019 (2016). https://doi.org/10.21272/jnep.8(4(1)).04019

M. Marinov, Thin Solid Films 46, 267 (1977). https://doi.org/10.1016/0040-6090(77)90182-1

N. Laegreid and G. K. Wehner, J. Appl. Phys. 32, 365 (1961). https://doi.org/10.1063/1.1736012

O. Monteiro, Proc. 33rd IUVSTA Workshop and IV Brazilian Meeting on Diamond, Diamond-Like, Nanotubes, Nitrides and Silicon Carbide, Brazil, 2001.

J. Bruley, D. B. Williams, J. J. Cuomo, and D. P. Pappas, J. Microsc. 180, 22 (1995). https://doi.org/10.1111/j.1365-2818.1995.tb03653.x

N. Bernier, F. Bocquet, A. Allouche, W. Saikaly, C. Brosset, J. Thibault, and A. Charai, J. Electron Spectrosc. Relat. Phenom. 164, 34 (2008). https://doi.org/10.1016/j.elspec.2008.04.006

B. André, F. Rossi, A. van Veen, P. E. Mijnarends, H. Schut, and M. P. Delplancke, Thin Solid Films 241, 171 (1994). https://doi.org/10.1016/0040-6090(94)90420-0

R. G. Lacerda, P. Hammer, F. L. Freire, F. Alvarez, and F. C. Marques, Diamond Relat. Mater. 9, 796 (2000). https://doi.org/10.1016/S0925-9635(99)00326-X

ACKNOWLEDGMENTS

We are grateful to S.S. Abramchuk for providing transmission-electron-microscopy data.

Funding

I. A. Zavidovskiy is a fellow of the Foundation for the Development of Theoretical Physics and Mathematics “Basis” (grant no. 20-2-2-7-1). The study was supported by the Russian Foundation for Basic Research within the framework of scientific project no. 20-32-90 077. The study was supported by the Interdisciplinary Scientific and Educational School of Moscow University “Photonic and Quantum Technologies. Digital Medicine.”

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

We declare that we have no conflicts of interest.

Additional information

Translated by O. Zhukova

Rights and permissions

About this article

Cite this article

Zavidovskiy, I.A., Streletskiy, O.A. & Nishchak, O.Y. Effect of Ion Assistance on the Formation of Composite Carbon–Silver Coatings Obtained by Pulsed-Plasma Deposition. J. Surf. Investig. 16, 864–869 (2022). https://doi.org/10.1134/S102745102205041X

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S102745102205041X