Abstract

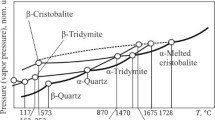

The structure of high-purity natural quartz (superquartzite) is investigated by the methods of X-ray diffraction and electron backscatter diffraction. The change in the crystallinity index obtained by the method of Murata and Norman and the impurity chemical composition of superquartzite at various technological stages of separation (thermal crushing, sieving, chemical etching, high-temperature calcination) is established. Quartz purification by etching with a mixture of hydrochloric and hydrofluoric acids is found to increase the crystallinity index at all stages, except for preliminary thermal crushing and high-temperature calcination (at 1300 or 1400°C). The maximum value of the quartz crystallinity index is reached at the first stage of chemical etching. The greatest purification from impurities also occurred at the first stage of chemical etching. Electron backscatter diffraction reveals areas of increased local misorientation of crystallites, which are concentrated at the grain boundaries, “low-angle” boundaries (with a misorientation angle of less than 7°) and areas with an increased content of fluid inclusions, which can be observed in an optical microscope. An “orientation map” and map of local crystallite misorientation regions are constructed and analyzed using the MTEX software toolkit for MATLAB. It is determined that macrodefects of a dislocation nature cause a change in the crystallinity index.

Similar content being viewed by others

REFERENCES

P. Aparicio and E. Galan, Clays Clay Miner. 47, 12 (1999). https://doi.org/10.1346/CCMN.1999.0470102

S. Guggenheim, D. C. Bain, F. Bergaya, et al., Clays Clay Miner. 50, 406 (2002). https://doi.org/10.1346/000986002760833783

S. Park, J. O. Baker, M. E. Himmel, P. A. Parilla, and D. K. Johnson, Biotechnol. Biofuels 3, 1 (2010). https://doi.org/10.1186/1754-6834-3-10

K. J. Murata and M. B. Norman, Am. J. Sci. 276, 1120 (1976). https://doi.org/10.2475/ajs.276.9.1120

R. V. Sadovnichii, A. A. Mikhailina, N. N. Rozhkova, and I. S. Inina, Tr. Karel’sk. Nauchn. Tsentra Ross. Akad. Nauk, No. 2, 73 (2016). https://doi.org/10.17076/geo126

N. Marinoni and M. A. Broekmans, Cem. Concr. Res. 54, 215 (2013). https://doi.org/10.1016/j.cemconres.2013.08.007

A. S. A. A. Abu Sharib and M. R. Abukhadra, Silicon 13, 653 (2021). https://doi.org/10.1007/s12633-020-00458-6

A. V. Peskov, E. V. Alekina, and E. Yu. Tarasova, Usp. Sovrem. Estestvozn., No. 11, 95 (2020). https://doi.org/10.17513/use.37521

H. Takagi, K. Takahashi, K. Shimada, K. Tsutsui, R. Miura, N. Kato, and S. Takizawa, J. Struct. Geol. 35, 64 (2012). https://doi.org/10.1016/j.jsg.2011.11.008

A. P. Zhaboedov, M. D. Zimin, A. I. Nepomnyashchikh, and A. N. Sapozhnikov, Obogashch. Rud, No. 1, 36 (2020). https://doi.org/10.17580/or.2020.01.07

K. Nagashima, R. Tada, A. Tani, S. Toyoda, Y. Sun, and Y. Isozaki, Geochem. Geophys. Geosyst. 8 (2) (2007). https://doi.org/10.1029/2006GC001364

N. Meftah and M. S. Mahboub, Silicon 12, 147 (2020). https://doi.org/10.1007/s12633-019-00109-5

A. M. Fedorov, V. A. Makrygina, A. I. Nepomnyashchikh, and I. A. Eliseev, Geogr. Prir. Resur., No. 6, 55 (2016). https://doi.org/10.21782/GIPR0206-1619-2016-6(55-59)

R. Haus, S. Prinz, and C. Priess, in Quartz: Deposits, Mineralogy and Analytics (Springer, Berlin, 2012), p. 29. https://doi.org/10.1007/978-3-642-22161-3_2

A. I. Nepomnyashchikh, M. G. Volkova, A. P. Zhaboedov, et al., Glass Phys. Chem. 44, 130 (2018). https://doi.org/10.1134/S1087659618020128

F. Bachmann, R. Hielscher, and H. Schaeben, Solid State Phenom. 160, 63 (2010). https://doi.org/10.4028/www.scientific.net/SSP.160.63

L. Pagliari, M. Dapiaggi, A. Pavese, and F. Francescon, J. Eur. Ceram. Soc. 33, 3403 (2013). https://doi.org/10.1016/j.jeurceramsoc.2013.06.014

A. M. Fedorov, V. A. Makrygina, A. E. Budyak, and A. I. Nepomnyashchikh, Dokl. Earth Sci. 442, 120 (2012). https://doi.org/10.1134/S1028334X12010126

M. Domanski and J. A. Webb, J. Archaeolog. Sci. 19, 601 (1992). https://doi.org/10.1016/0305-4403(92)90031-W

M. G. Volkova, A. I. Nepomnyashchikh, A. M. Fedorov, A. M. Makhlyanova, and N. V. Bryanskii, Geol. Geofiz. 58, 1324 (2017). https://doi.org/10.15372/GiG20170905

C. Rößler, B. Möser, C. Giebson, and H. M. Ludwig, Cem. Concr. Res. 95, 47 (2017). https://doi.org/10.1016/j.cemconres.2017.02.015

Funding

This work was carried out within the framework of state task (project no. 0284-2021-0004 “Materials and technologies for the development of radiation detectors, phosphors, and optical glasses”).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

We declare that we have no conflicts of interest.

Additional information

Translated by Yu. Ryzhkov

Rights and permissions

About this article

Cite this article

Zimin, M.D., Zhaboedov, A.P., Kolesnikov, S.S. et al. Measurement of the Crystallinity Index of High-Purity Quartz at Various Stages of Separation and Study of Its Structure by X-Ray Diffraction and Electron Backscatter Diffraction. J. Surf. Investig. 16, 484–489 (2022). https://doi.org/10.1134/S102745102204019X

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S102745102204019X