Abstract

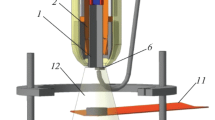

CrAlSiC films deposited under various conditions of carbon-plasma generation (PVD or PACVD) are investigated. A plasma source of cathodic-arc discharge with a Cr–Al–Si cathode and a source of pulsed cathodic-arc discharge with a graphite cathode are used for the deposition of a CrAlSiC(I) film. A plasma source of cathodic-arc discharge with a Cr–Al–Si cathode and a gas-discharge device for generating a non-self-sustaining discharge in an argon-acetylene mixture are applied for the deposition of a CrAlSiC(II) film. The sources work together in both processes. The film structure is investigated using electron microscopy and Raman spectroscopy. The hardness and elasticity modulus are determined by nanoindentation; the friction coefficient is tested with the reciprocating motion of a steel ball without lubrication. It is found that the condition of generating carbon plasma (graphite sputtering or destruction of acetylene) has a significant effect on the structure and properties of CrAlSiC. CrAlSiC(I) consists of an amorphous phase with inclusions of silicon-carbide nanograins 10–30 nm in size. On the surface there are protrusions with a size of 2–4 µm. These features provide a high hardness and low friction coefficient. No crystalline formations are found in the amorphous matrix of CrAlSiC(II). On the surface there are bubble-like formations up to 15 microns in size. This coating is inferior to CrAlSiC(I) in terms of hardness and resistance to friction. Under friction the film is destroyed by chipping fragments. CrAlSiC(I) can be recommended for practical application.

Similar content being viewed by others

REFERENCES

N. Kumar, G. Natarajan, R. Pandian, A. Bahuguna, S. K. Srivastava, T. R. Ravindran, S. Rajagopalan, S. Dash, A. K. Tyagi, R. Dumpala, and M. S. Ramachandra Rao, Surf. Coat. Technol. 258, 557 (2014). https://doi.org/10.1016/j.surfcoat.2014.08.038

A. B. Vladimirov, S. A. Plotnikov, I. Sh. Trakhtenberg, A. P. Rubshtein, and E. G. Volkova, Prot. Met. Phys. Chem. Surf. 51, 230 (2015). https://doi.org/7868/S0044185615020199

I. Sh. Trakhtenberg, N. V. Gavrilov, D. R. Emlin, S. A. Plotnikov, A. B. Vladimirov, E. G. Volkova, and A. P. Rubshtein, Phys. Metals Metallogr. 115, 723 (2014). https://doi.org/10.1134/S0031918X14070102

A. P. Rubshtein, A. B. Vladimirov, Yu. V. Korkh, Y. S. Ponosov, and S. A. Plotnikov, Surf. Coat. Technol. 309, 680 (2017). https://doi.org/10.1016/j.surfcoat.2016.11.020

V. M. Finkel’, Physical Bases of Inhibition of Destruction (Metallurgiya, Moscow, 1977).

H. Gleiter, Acta Mater. 48, 1 (2000). https://doi.org/10.1016/S1359-6454(99)00285-2

A. S. Vereshchaka and A. A. Vereshchaka, Uprochnyayushchie Tekhnol. Pokrytiya, No. 9, 9 (2005).

A. P. Rubshtein, K. Gao, A. B. Vladimirov, S. A. Plotnikov, B. Zhang, and J. Zhang, Surf. Coat. Technol. 377, 124912 (2019). https://doi.org/10.1016/j.surfcoat.2019.124912

T. C. Fu and G. W. Li, Appl. Surf. Sci. 253, 1260 (2006). https://doi.org/10.1016/j.apsusc.2006.01.069

A. P. Rubshtein, A. B. Vladimirov, and S. A. Plotnikov, Solid State Phenom. 279, 160 (2018). https://doi.org/10.4028/www.scietific.net/SSP.279.153

A. P. Rubshtein, A. B. Vladimirov, and S. A. Plotnikov, J. Phys.: Conf. Ser. 1281, 12065 (2019). https://doi.org/10.1088/1742-6596/1281/1/012065

J. L. Jiang, Q. Wang, H. Huang, Y. B. Wang, X. Zhang, and J. Y. Hao, Surf. Coat. Technol. 240, 419 (2014). https://doi.org/10.1016/j.surfcoat.2013.12.067

M. Rybachuk and J. M. Bell, Thin Solid Films 515, 7855 (2007). https://doi.org/10.1016/j.tsf.2007.04.040

P. A. Topolyanskii, S. A. Ermakov, N. A. Sosnin, and A. P. Topolyanskii, Metalloobrabotka, No. 4, 28 (2013).

A. Leyland and A. Matthews, Wear 246, 1 (2000). https://doi.org/10.1016/S0043-1648(00)00488-9

D. V. Shtanskii, S. A. Kulinich, E. A. Levashov, and J. J. Moore, Phys. Solid State. 45, 1177 (2003).

A. P. Rubshtein, V. A. Zavalishin, A. B. Vladimirov, and S. A. Plotnikov, Vacuum Engineering and Technologies 2020: Proceedings of the 27th All-Russian Scientific and Technical Conference with International Participation, Ed. by D. K. Kostrina and S. A. Martsynyukova (LETI, St. Petersburg, 2020), p. 123. https://vtt.etu.ru/assets/files/sbornik_vtt-2020.pdf.

Funding

The work was carried out within the framework of the state assignment of the Ministry of Education and Science of Russia (topic “Function” No. АААА-А19-119012990095-0, topic “Structure” No. АААА-А18-118020190116-6). Electron microscopic studies were performed at the OEM of the Center for Collective Use of the Mikheev Institute of Metal Physics, Ural Branch, Russian Academy of Sciences.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Rubshtein, A.P., Vladimirov, A.B., Plotnikov, S.A. et al. Structure and Properties of CrAlSiC Films Deposited by the Vacuum-Plasma Technique under Various Conditions. J. Surf. Investig. 15, 961–965 (2021). https://doi.org/10.1134/S1027451021050153

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S1027451021050153