Abstract

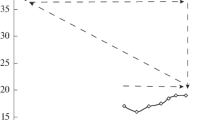

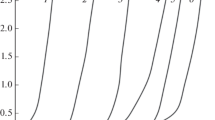

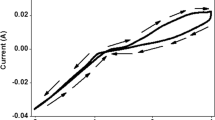

Heating of chloride electrolyte up to 70°С ensures the normal codeposition of components of the Co–Ni–Fe alloy as a result of the discharge of iron, cobalt, and nickel ions at the high cathodic current density. The chloride electrolyte with filtration and pH correction by hydrochloric acid at the concentration CСо : CNi : CFe = 1 : 1 : 1 provides the electrochemical deposition of Co–Ni–Fe films. The mechanism of anomalous deposition of Co, Fe, and Ni takes place due to the incomplete ionization of atoms and the different mobility of ions. The Co–Ni–Fe films lacking mechanical stresses with the uniform structure and the high magnetic properties are synthesized without using high annealing temperatures. The electrochemical deposition allows reproducible Co–Ni–Fe films to be obtained.

Similar content being viewed by others

REFRENCES

Tikhonov, R., Congruent Electrochemical Deposition of Ni–Fe Alloy, Lambert Acad., 2019.

Tikhonov, R.D., Electrochemical deposition of NiFe alloy at a temperature of 70°C, Russ. J. Electrochem., 2020, vol. 56, p. 611]

Fedot’ev, N.P., Alabyshev, A.F., Rotinyan, A.L., Vyacheslavov, P.M., Zhivotinskii, P.B., and Gal’nbek, Prikladnaya Elektrokhimiya, (Applied Electrochemistry), Goskhimizdat, 1962.

Gamburg, Yu.D. and Zangari, G., Theory and Practice of Metal Electrodeposition, New York: Springer, 2011.

Tikhonov, R.D., Cheremisinov, A.A., Gorelov, D.V., and Kazakov, Yu. V., Magnetic properties of Co–Ni–Fe films synthesized by electrochemical deposition by the Tikhonov method, Nano- Mikrosist. Tekh., 2020, vol. 22, p. 123.

Tikhonov, R.D., Features of electrochemical deposition of films of the triple system of the Co-Ni-Fe, EJERS, 2021, vol. 6, p. 19.

Tikhonov, R.D., Cheremisinov, A.A., and Tikhonov, M.R., Ion discharge in electrochemical deposition of Co–Ni–Fe films, Russ. J. Electrochem., 2021, vol. 57, p. 1151.

Tikhonov, R.D., Polomoshnov, S.A., Amelichev, V.V., Cheremisinov, A.A., and Kovalev, A.M., Formation of films in the ternary system Co–Ni–Fe by electrodeposition, Izv. Vyssh. Uchebn. Zaved., Elektron., 2021, vol. 26, p. 246.

Damaskin., B.B., Petrii, O.A., and Tsirlina, O.A., Elektrokhimiya (Electrochemistry), St. Petersburg: Lan’, 2015.

Nakano, H., Matsuno, M., Oue, S., Yano, M., Kobayashi, Sh., and Fukushima, H., Mechanism of anomalous type electrodeposition of Fe-Ni alloys from sulfate solutions, Trans. Jpn. Inst. Met., 2004, vol. 45, p. 3130.

Hanafi, I., Daud, A.R., and Radiman, Sh., Potentiostatic electrodeposition of Co–Ni–Fe thin films from sulfate medium, J. Chem. Technol. Metall., 2016, vol. 51, p. 547.

Park, D.Y., Yoo, B.Y., Kelcher, S., and Myung, N.V., Electrodeposition of low-stress high magnetic moment Fe-rich Fe–Co–Ni thin films, Electrochim. Acta, 2006, vol. 51, p. 2523.

Kim, Jin-Soo, Kwak, Jun-Ho, Na, Seong-Hun, Lim, Seung-Kyu, and Suh, Su-Jeong, The deposit stress behavior and magnetic properties of electrodeposited Ni‒Co–Fe ternary alloy films, J. Korean Phys. Soc., 2012, vol. 61, p. 21.

Chason, E., Measurement of stress evolution in thin films using real-time in situ wafer curvature(k-SpaceMOS), https//www.k-space.com›wp-content/uploads/MOSforThinFilms.

Korovin, N.V., Obshchaya Khimiya (General Chemistry), Moscow: Vysshaya Shkola, 1998.

Beloglazov, S.M., Elektrokhimicheskii vodorod i metally (Electrochemical Hydrogen and Metals), Kaliningrad: KGU, 2004.

Osaka, T., Sawaguchi, T., Mizutani, F., Yokoshima, T., Takai, M., and Okinaka, Y., Effects of saccharin and thiourea on sulfur inclusion and coercivity of electroplated soft magnetic Co-Ni-Fe film, J. Electrochem. Soc., 1999, vol. 146, p. 3295.

Zech, N., Podlaha, E.J., and Landolt, D., Anomalous codeposition of iron group metals I. Experimental results, J. Electrochem. Soc., 1999, vol. 146, p. 2886.

Tabakovic, I., Riemer, S., Inturi, V., Jallen, P., and Thayer, A., Organic additives in the electrochemical preparation of soft magnetic Co-Ni-Fe films, J. Electrochem. Soc., 2000, vol. 147, p. 219.

Tobakovic, I., Inturi, V., and Riemer, S., Composition, structure, stress, and coercivity of electrodeposited soft magnetic Co–Ni–Fe films, J. Electrochem. Soc., 2002, vol. 149, p. 18.

Perez, L., Attenborough, K., De Boeck, J., Celis, J.P., Aroca, C., Sánchez, P., López, E., and Sánchez, M.C., Magnetic properties of Co–Ni–Fe alloys electrodeposited under potential and current control conditions, J. Magn. Magn. Mater., 2002, vols. 242–245, p. 163.

Kim, D., Park, D.Y., Yoo, B.Y., Sumodjo, P.T.A., and Myung, N.V., Magnetic properties of nanocrystalline iron group thin film alloys electrodeposited from sulfate and chloride baths, Electrochim. Acta, 2003, vol. 48, p. 819.

Huang, Q. and Podlaha, E.J., Simulation of pulsed electrodeposition for giant magnetoresistance Fe–Co–Ni–Cu/Cu multilayers, J. Electrochem. Soc., 2004, vol. 151, p. 119.

Khomenko, E.V., Shalygina, E.E., Polyakov, S.N., and Checherin, N.G., Electrochemical deposition and properties of ferromagnetic films Co–Fe–Ni with the thickness up to 500 nm, Perspekt. Mater., 2006, vol. 2, p. 66.

Khomenko, E.V., Shalyguina, E.E., and Chechenin, N.G., Magnetic properties of thin Co–Fe–Ni films, J. Magn. Magn. Mater., 2007, vol. 316, p. 451.

Yun, T. and Jiang, W., Effects of additives on magnetic properties of electroplated Co-Ni-Fe films, Master’s Theses, San Jose State University, 2008.

Rohan, J.F., Ahern, B.M., Reynolds, K., Crowley, S., Healy, D.A., Rhen, F.M.F., and Roy, S., Electroless thin film Co–Ni–Fe–B alloys for integrated magnetics on Si, Electrochim. Acta, 2009, vol. 54, p. 1851.

Péter, L., Csik, A., Vad, K., Toth-Kadar, E., Pekker, A., and Molnár, G., On the composition depth profile of electrodeposited Fe–Co–Ni alloys, Electrochim. Acta, 2010, vol. 55, p. 4734.

Sundaram, K., Dhanasekaran, V., and Mahalingam, T., Structural and magnetic properties of high magnetic moment electroplated Co–Ni–Fe thin films, Ionics, 2011, vol. 17, p. 835.

Phua, L.X., Phuoc, N.N., and Ong, C.K., Effect of Ni concentration on microstructure, magnetic and microwave properties of electrodeposited Ni–Co–Fe films, J. Alloys Compd., 2012, vol. 543, p. 1.

Gong, J., Riemer, S., Morrone, A., Venkatasamy, V., Kautzky, M., and Tabakovic, I., Composition gradients and magnetic properties of 5–100 nm thin Co–Ni–Fe films obtained by electrodeposition, J. Electrochem. Soc., 2012, vol. 159, p. 447.

Li, J.-M., et al., Effect of boron/ phosphorus containing additives on electrodeposited Co–Ni–Fe soft magnetic thin films, Trans. Nonferrous Met. Soc. China, 2013, vol. 23, p. 674.

Kockar, H., Demirbas, O., Kuru, H., and Alper, M., Differences observed in properties of ternary Ni–Co–Fe films electrodeposited at low and high pH, J. Mater. Sci.: Mater. Electron., 2013, vol. 24, p. 1961.

Azizi, A., Yourdkhani, A., Cutting, D., and Pesika, N., Tuning the crystal structure and magnetic properties of Co–Ni–Fe–B thin films, Chem. Mater., 2013, vol. 25, p. 2510.

Valko, N.G. and Gurtovoy, W.G., Structure and properties of coatings Co−Ni−Fe, electrolytically besieged by X-ray radiation, Fiz. Tverd. Tela, 2013, vol. 55, p. 2086.

Kayani, Z.N., Riaz, S., and Naseem, Sh., Structural and magnetic properties of Fe–Co–Ni thin films, Indian J. Phys., 2014, vol. 88, p. 17.

Kuru, C.H., Kockar, H., Demirbas, O., and Alper, M., Characterizations of electrodeposited Ni–Co–Fe ternary alloys: Influence of deposition potential, J. Sci. Mater., 2015, vol. 26, p. 4046.

Watanabe, Yo., Otsubo, M., Takahashi, A., and Fukunaga H., Temperature characteristics of a fluxgate current sensor with Fe–Ni–Co ring core</b, IEEE Trans. Magn., 2015, vol. 51, p. 1.

Kourov, N.I., Pushin, V.G., Korolev, A.V., Knyazev, Yu.V., and Ivchenko, M.V., Peculiar features of physical properties of the rapid quenched Al–Cr–Fe–Co–Ni–Cu high-entropy alloy, J. Alloys Compd., 2015, vol. 636, p. 304.

Romankov, S., Park, Y.C., and Shchetinin, I.V., Mechanical intermixing of elements and self-organization of (Fe–Ni) and (Co–Fe–Ni) nanostructured composite layers on a Ti sheet under ball collisions, J. Alloys Compd., 2015, vol. 653, p. 175.

Yanai, T., and all, Electroplated Fe–Co–Ni films prepared from deep-eutectic-solvent-based plating baths, AIP Adv., 2016, vol. 6, p. 917.

Eguchi, K., Azuma, K., Akiyoshi, T., and Fukunaga, H., DC/pulse plating of Fe-Ni-Co films, 2016, Int. Conf. Asian Union Magn. Soc. (ICAUMS).

Yanai, T., Koda, K., Eguchi, K., and Takashima, K., Effect of ammonium chloride in plating baths on soft magnetic properties of electroplated Fe–Ni films, IEEE Trans. Magn., 2017, vol. 99, p. 1.

Li, D. and Podlaha, E., Template-assisted electrodeposition of Fe–Ni–Co nanowires: Effects of electrolyte pH and sodium lauryl sulfate, J. Electrochem. Soc., 2017, vol. 164, p. D843.

Yanai, T., and all, Electroplated Fe–Co–Ni films prepared in ammonium-chloride-based plating baths, AIP Adv., 2018, vol. 8(056127), p. 1.

Romankov, S., Park, Y.C., and Shchetinin, I.V., Structural transformations in (Co–Fe–Ni)/Ti nanocomposite systems during prolonged heating, J. Alloys Compd., 2018, vol. 745, p. 44.

Tabakovic, I. and Venkatasamy, V., Preparation of metastable Co–Fe–Ni alloys with ultra-high magnetic saturation (B s = 2.4–2.59 T) by reverse pulse electrodeposition, J. Magn. Magn. Mater., 2018, vol. 452, p. 306.

Zaharov, Yu.A., Pugachev, V.M., Ovcharenko, V.I., Datiy, K.A., Popova, A.N., and Bogomyakov, A.S., Phase composition and magnetic properties of nanostructured Fe–Co–Ni powders, Phys. Status Solidi B, 2018, vol. 255:170175, p. 1.

Cesiulis, H., Tsyntsaru, N., Podlaha, E.J., Li, D., and Sort, J., Electrodeposition of iron-group alloys into nanostructured oxide membranes: Synthetic challenges and properties, Curr. Nanosci., 2019, vol. 15, p. 84.

Budi, S., Muhab, S., Purwanto, A., Kurniawan, B., and Manaf, A., Effect of the electrodeposition potential on the magnetic properties of FeCoNi films, Mater. Sci.-Pol., 2019, vol. 37, p. 389.

Milyaev, M.A., Bannikova, N.S., Naumova, L.I., Proglyado, V.V., Patrakov, E.I., Kamenskii, I.Yu. and Ustinov, V.V., Magnetoresistance of Co–Ni–Fe/Cu superlattices with different composition of the ferromagnetic alloy, Fiz. Met. Metalloved., 2019, vol. 120, p. 905.

Saraç, U., Kaya, M., and Baykul, M.C., A comparative study on microstructures, magnetic features and morphologies of ternary Fe–Co–Ni alloy thin films electrochemically fabricated at different deposition potentials, J. Supercond. Novel Magn., 2019, vol. 32, p. 917.

Shekhanov, R.F., Electrodeposition of alloys containing iron-group metals from polyligand electrolytes, Doctoral Dissertation, Ivanovo, 2020.

Ledwig, P., Kac, M., Kopia, A., Falkus, J., and Dubiel, B., Microstructure and properties of electrodeposited nanocrystalline Ni–Co–Fe coatings, Mater. Sci., 2021, https://www.researchgate.net/publication/353213741.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

The authors declare that they have no conflict of interest.

Additional information

Translated by T. Safonova

Rights and permissions

About this article

Cite this article

Tikhonov, R.D., Cheremisinov, A.A. & Tikhonov, M.R. Congruent Electrochemical Deposition of Co–Ni–Fe Films. Russ J Electrochem 58, 1094–1102 (2022). https://doi.org/10.1134/S1023193522120072

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S1023193522120072