Abstract

The work reviewed here attempts to summarize the growing literature on zeolite stability in hot liquid water. This required to first establish the nature, structure and interactions of the active sites in Brønsted and Lewis acidic microporous materials in the presence of liquid water. This understanding was then transferred to zeolite stability and catalyst deactivation. While early results correctly established Si–O–Si hydrolysis as the dominant pathway compared to the Si–O–Al hydrolysis observed in steaming, it also focused extensively on the positive role of framework and extra-framework Al in stabilizing zeolites. However, stability was instead found to more directly correlate with the number of internal structural defects and intraporous water concentration. Stabilization protocols for Brønsted acidic zeolites are described in detail. In the case of Lewis acidic zeolites, their inherent hydrophobic behavior (Si/M >100) makes them more resistant towards water, however, issues such as reversible carbonaceous species formation as well as irreversible metal leaching and fouling remain. Finally, we summarize the most important factors in designing robust and efficient zeolite catalysts made to withstand hot liquid water.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Zeolites can be classified as porous aluminosilicates where a tetrahedrons (TO4, T = Si or Al), linked with each other via the oxygen atoms in their vertices form an expansive network. This results in a myriad of different possible orientations creating a low-density, three-dimensional network. At the same time, this also creates well-defined and uniform pores with diameters <2 nm, thus being a microporous material with an exceedingly large internal surface area. Due to the molecular dimensions of these pores, the crystalline materials have found widespread use in a number of industrial processes related to the preferential sieving of molecules. Isomorphous substitution of Si in the framework with aliovalent heteroatoms such as Al, B, Fe introduces an imbalance in the framework charge which needs to be compensated by metal cations or protons. The latter results in the zeolite acting as a strong Brønsted solid acid [1]. In combination with their ability to screen molecules based on their porous constraints, this makes zeolites ideal candidates for the shape-selective catalysis necessary in the production of many fine and commodity chemical products [1–3]. Another valuable characteristic of zeolites is their high thermal and hydrothermal stability which allows them to be used at temperatures above 600°C, especially at higher Si/Al ratios [4]. Structural collapse occurs eventually as the zeolite is completely dehydrated [5]. Upon heating, the loss of water leads to a contraction of the unit cell, breaking of T–O–T bonds and transformation to denser phases such as cristobalite or quartz. It should be noted here, that a zeolite is a metastable species, being only 0–7 kJ/mol more stable than its starting material of amorphous SiO2 while the dense phases are thermodynamically favored by 7–14 kJ/mol [6, 7]. Thus, the preparation of zeolites underlies kinetic control implying that given a sufficiently long time frame they will transform to thermodynamically more favored phases [8]. High temperatures promote this transformation and the incorporation of heteroatoms (e.g. Al) results in a more hydrophilic material containing more adsorbed water as well as generating, compared to Si–O bonds (bond dissociation energy: 800 kJ/mol) [9], weaker Al−O bonds (bond dissociation energy: 511 kJ/mol) [9]. Especially in the presence of steam, the adsorption of water facilitates the hydrolysis of Si–O(H)–Al bonds generating extra-framework species and under more extensive steaming conditions mesopores which could lead to the eventual collapse of the structure [10–13]. The hydrothermal stability of zeolites can be improved at higher Si/Al ratios but also by incorporating extra-framework metal cations that displace the protons and thus minimize framework hydrolysis [4, 14]. This has been shown in the case of the FCC catalyst, part of which is a highly dealuminated FAU type material (USY—ultra-stable Y zeolite) doped with extra-framework rare-earth metals (e.g La, Ce, Sm, etc.) [15, 16]. The introduction of metal cations to stave off dealumination has also been successfully applied in exhaust gas treatment, where alkali as well as divalent Cu ions block the Al sites from being exposed to steam thus minimizing the extent of dealumination [17–19].

The material properties influencing the shape-selective catalytic properties as well as hydrothermal stability of zeolites in gas phase reactions have been studied extensively over the last 50–60 years, owing to their application in the upgrading of crude oil. However, an increased focus on cleaner and more sustainable energy and chemical production has led to research interest shifting to zeolite catalysts employed in low-temperature catalysis. One of the interesting and challenging new areas being explored is the transformation of biomass into fuels [20] and value added chemicals [21] for which zeolites have been identified as a promising candidate [20, 22, 23]. However, commercialization of these processes is limited on the need to perform them in a decentralized process with the conversion of the feed on site [24]. As such, a major constituent of the feed is water and this poses a challenge to zeolite catalysts as the solvent effects of water on low-temperature catalysis, or rather, aqueous phase catalysis as well as the stability of the materials under these conditions had not been studied extensively in the past.

Biomass is a broad term encompassing resource streams of lignocellulose, lipids, vegetables, algae and turpentine. Lignocellulose promises to be a very valuable and versatile resource containing a wide variety of chemical compounds, such as lignin (mainly phenolic compounds), cellulose (sugars) and hemicellulose (sugars). These biopolymers first must be processed into smaller platform molecules (e.g. phenols, glucose, xylose, hydroxymethylfurfural) which have the potential to be transformed into many value-added chemicals [21, 25]. Most of these biomass upgrading reactions are catalyzed by Lewis or Brønsted acidic catalysts in addition to selective reduction reactions [22]. The latter is owed to the significantly lower C/O ratio in biomass compared to conventional oil feeds [26]. These deoxygenation processes can be typically catalyzed by metal functions in materials as part of a bifunctional catalyst or in separate reactions and will not be the focus of this review [23]. In addition to the high oxygen content biomass also contains 15–30 wt % H2O and in order for biorefineries to compete with conventional oil refineries, a near full utilization of the feedstock has to be achieved in order to minimize any waste [24, 27]. There are several expansive scientific reviews that capture the whole range of biomass upgrading reactions catalyzed by zeolite and other heterogenous acids and the reader is referred to those for obtaining an overview of all potential reactions [21, 22].

However, the more fundamental understanding of the effect hot liquid water has on the catalytic and structural properties of zeolites has not been captured extensively in a review. Therefore, the purpose of this review aims to be twofold. Firstly, we will discuss recent fundamental insights into the use of zeolites in aqueous phase catalysis and then this will be followed by an extensive and detailed look at our understanding of zeolite stability in aqueous phase reactions.

Zeolite Catalysis in the Presence of Hot Liquid Water—Brønsted Acid Catalysis

As has been discussed, zeolite catalysts are advantageous over other heterogeneous catalysts due to their pores approaching molecular dimensions enabling shape selective catalysis. In the case of biomass, the typical size of substrate molecules prevents the use of small pore zeolites and instead large pore zeolites, such as FAU, BEA and to a lesser extent the medium pore zeolite MFI are typically used. As a result, most research has focused on studying the conversion of biomass-derived, relevant probe molecules such as cyclohexanol, glucose or phenol in the presence of water. Due to the high oxygen content of biomass resulting in low vapor pressure, these processes are typically investigated in liquid phase conditions, resulting in water being heated above its boiling point and being described as hot liquid water (HLW).

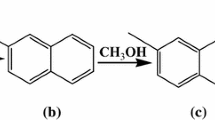

For example, Lercher et al. have extensively investigated the transformation of lignin-derived, hexane-extracted, crude bio-oil into hydrocarbons as a multi-step process performed in the presence of hot liquid water [23]. 20 wt % Ni clusters supported on H-ZSM-5 (Si/Al 45) was an effective bi-functional catalyst. Part of the Ni was located within the zeolite pores, where the proximity to the acid sites facilitates the tandem reaction with up to 85% yield towards the hydrocarbons. It could even be extended towards phenolic ethers with the cleavage yielding nearly 100% C6 or C7 hydrocarbons (starting from C13 and C14, respectively). This hydrodeoxygenation (HDO) sequence can be broken into an initial hydrogenation of the phenol, subsequent dehydration of the cyclohexanol molecule and finally a second hydrogenation step to yield cyclohexane. In addition, they also investigated the hydroalkylation reaction of phenol using a bifunctional catalyst consisting of Pd supported on H-BEA zeolite [28, 29]. The solvent in all cases was hot liquid water. The rate determining step in both the HDO and hydroalkylation sequences was the acid-catalyzed dehydration or alkylation of cyclohexanol [30]. They established that the inherent acid properties of the zeolite catalyze the dehydration and alkylation step. It was noted that the zeolite exhibited, compared to a homogeneous phosphoric acid catalyst, a superior intrinsic activity in the dehydration step by up to 2 orders of magnitude (1600 mol \({\text{mol}}_{{{{{\text{H}}}^{ + }}}}^{{ - 1}}\,\,{{{\text{h}}}^{{ - 1}}}\) vs 15 mol \({\text{mol}}_{{{{{\text{H}}}^{ + }}}}^{{ - 1}}\,\,{{{\text{h}}}^{{ - 1}}}\)). Early in their work they associated this with a preferential adsorption of the substrate molecules within the zeolite pores as well as the pore constraints preventing the formation of alcohol dimers within the pores, thus promoting the dehydration of the monomer [23]. This enhancement effect attributed to the porous network was explored further for the dehydration of aqueous cyclohexanol catalyzed by H-BEA, a large pore 12-membered ring (MR) zeolite. To investigate the mechanism more closely and elicit the origin of the enhancement they used in situ 13C MAS NMR studies and found the mechanism to be of the E1 type [31]. This implies that the formation of the carbocation is crucial and H/D exchange allowed for the assessment of the kinetic isotope effect being significant (ca. 3) which indicates the C-H(D) bond cleavage to be the rate determining step [32]. While it was generally accepted that the active site for these dehydration reactions is a proton balancing the negative framework charge it was through the use of infrared spectroscopy, 27Al MAS NMR and Al-extended X-ray absorption fine structure (EXAFS), that the active site is more complex [33]. In fact, zeolites, when immersed in water, form hydronium ion complexes, H3O+(H2O)n. These hydronium ion complexes can also be representative for homogeneous acids such as H3PO4, where Liu et al. established that in non-constrained environments the association of hydronium ions with the substrate molecule (e.g. cyclohexanol) was significantly smaller than in the case of the pores of zeolite BEA [32]. Furthermore, the intrinsic rate constant was several times larger in the case of constrained hydronium ions in zeolite pores. The measured enthalpy of activation was comparable in both cases (\(\Delta {\text{H}}{{^\circ }^{{_{ + }^{ + }}}}\) = 157 kJ mol–1 and \(\Delta {\text{H}}{{^\circ }^{{_{ + }^{ + }}}}\) = 159 kJ mol–1), however, the constrained environment leads to a higher gain in entropy of activation (\(\Delta {\text{S}}{{^\circ }^{{_{ + }^{ + }}}}\) = 73 J mol–1 K–1 and \(\Delta {\text{S}}{{^\circ }^{{_{ + }^{ + }}}}\) = 87 J mol–1 K–1, respectively). This was attributed to less mobile hydronium ions in the pores enhancing their association with the reactant similar to the key-lock principle in enzyme catalysis yielding ideal reactant-enzyme adducts that allow them to perform under very mild conditions and high selectivity [32]. Tailoring the size of the pores it is then possible to influence the reactivity of these hydronium ions. Increasing pore dimensions led to a decrease in the turnover frequency for cyclohexanol dehydration in the order MFI > BEA > FAU > H3PO4 (Scheme 1) [34]. While retaining largely the same degree of association between hydronium ions and cyclohexanol, the increase in pore size led to a more poorly solvated transition state as indicated by more positive changes in entropy and enthalpy of adsorption for cyclohexanol. The acidic strength of these hydronium ion complexes was found to be independent of the Si/Al [35], which is in contrast to the classical way of assessing Brønsted acid strength in zeolite where the number of next nearest neighbors determines the acid strength with it continuously becoming stronger as the Si/Al increases [1]. However, the modification of hydronium ion complexes does allow for positive or negative effects on intrinsic rates of dehydration. This has recently been suggested by Mei and Lercher through ab-initio AIMD calculations showing that a large hydronium ion complex (i.e. 26 H2O molecules in the pore) changes the protonation of the alcohol from a pre-equilibrated step to becoming an activated process [36]. At the same time, Eckstein et al. showed how an increasing concentration of (H2O)nH3O+ positively affects the activity coefficient of adsorbed substrates suggesting a destabilization of the substrate and subsequent weakening of the adsorption [37]. This could lead to improved rates of dehydration, and modification of activity coefficients (e.g. with the help of salts) promises to be an interesting next step. These studies clearly highlight how the successful application of zeolites in a new and challenging environment such as bio-oil upgrading eventually led to a new understanding of Brønsted acid sites within the confines of a zeolite in the presence of hot liquid water.

Scheme 1. The effect of confined water on active sites in aqueous phase catalysis represented for cyclohexanol dehydration over Brønsted acidic zeolites (left) [34] and 1-octene epoxidation over Lewis acidic zeolites (right) [38]. In both cases, confined water plays important role in being an entropically driving part of the activated process. Reprinted with permission from J. Am. Chem. Soc. 2019, 141, 18, 7302−7319. Copyright (2019) American Chemical Society.

Zeolite Catalysis in the Presence of Hot Liquid Water—Lewis Acid Catalysis

While Lercher et al. have extensively studied the role of hot liquid water on the catalytic activity of aluminosilicate zeolites another important class of biomass transformation is catalyzed by Lewis acid sites. Most zeolites contain Lewis acidic sites in the form of extra-framework Al generated inadvertently during high temperature calcination; however, another class of zeolite material is specifically designed to contain only Lewis acidic sites by including heteroatoms in the synthesis. This was first pioneered by ENI research in 1983 when they presented the successful synthesis of TS-1, a titanosilicate of the MFI framework type [39]. The scope of Lewis acidic zeolites was later widened by Corma and Valencia who introduced us to Sn and Ti incorporated BEA zeolites [40]. The field has proliferated since these early days with the successful synthesis of Lewis acidic zeolites containing Zr [41], Hf [42, 43], Nb [44] or Ta [44] heteroatoms. The resulting zeolites have found widespread use in oxidation (e.g. ethylene epoxidation) [45] isomerization reactions (e.g. Glucose to Fructose), transfer hydrogenation (e.g. Meerwein-Ponndorf-Verley reduction of carbonyl compounds) [46, 47], Diels-Alder reactions (e.g bio-derived furan and acrylic acid to form benzoic acid) [42], and many more possible routes. The reader is referred to focused reviews on the various possible reactions and preparation methods for metallo-zeolites by Moliner (reactions) [48], Roman-Leshkov (nature of active sites) [49] and Perez-Ramirez (design principles) [50].

In contrast to studies on aluminosilicates (e.g. MFI and BEA) reported previously, the metallosilicates are overall defined by their high degree of hydrophobicity. The origins of this remarkable hydrophobicity lie in the Si/M typically being in the range of 100, implying that the majority of the framework consists of SiO4 tetrahedra. In addition, most synthesis procedures require the use of hydrofluoric acid, which can reduce the concentration of internal silanol (SiOH) groups to a large extent. Thus, the internal confines are extremely hydrophobic enabling the use of these zeolites even in the presence of bulk water. Without any water molecules entering the pores (pressures as high as 100 MPa are required to push water in pure-silica Silicalite-1) [51], the nature of the Lewis acid sites (as electron accepting sites) is retained, facilitating the transformation of a large range of molecules. If more hydrophilic materials are used instead (e.g. by performing the synthesis in presence of hydroxide anions instead of fluoride anions, or the use of for example TiO2–SiO2), the coordination of water or other polar solvent molecules to the Lewis acid sites leads to a negative effect on the reaction rate [52, 53]. This coordination of solvent molecules as well as substrate molecules to the active site is facilitated by the transition metals having larger radii than Si. It allows them to exist in two distinct coordination states, either as a fully tetrahedrally coordinated T atom (i.e. a closed site) or as an open site where one of the Si–O–M bonds is hydrolyzed [54]. It has been shown that the latter open site is associated with high catalytic activity as the hydroxyl species are able to stabilize the transition state in reactions. The ambiguity of the active site is part of the reason why ongoing investigations still focus extensively on understanding the nature of the active site. For example, it has recently been found that in the case of 1-octene epoxidation over Ti-BEA, material prepared with higher concentrations of SiOH exhibited higher turnover rates for the epoxidation reaction [38]. This is in direct contrast to the understanding that TiO2–SiO2 is inactive for the epoxidation of 1-octene in the presence of aqueous H2O2 due to the active site not being confined in hydrophobic zeolite pores. The authors concluded that the enhancement comes from SiOH nests stabilizing small water clusters, which are then able to interact with the epoxidation transition state. The size of the transition state requires the water clusters to restructure which induces entropic gain and thus compensates the enthalpic loss compared to defect-free Ti-BEA (Scheme 1). This reduces the overall free energy of activation of the reaction leading to a 100 times faster turnover rate for the most hydrophilic Ti-BEA compared to the most hydrophobic Ti-BEA. Interestingly, this insight is comparable to that achieved for hydronium ion catalysis in confined spaces reported by Lercher et al [32].

Al-Zeolite Stability in the Presence of Hot Liquid Water On the Impact of Framework and Extra-framework Al on Zeolite Stability

While many studies have focused on investigating the catalytic properties of both Brønsted and Lewis acidic zeolites in the presence of hot liquid water, an important question that needed to be answered was the material’s respective stability under these conditions. Biomass feedstocks are rich in water (15–30 wt %) as well as oxygenated compounds and other feed impurities. In a certain light, one could compare typical process conditions to those found during hydrothermal synthesis (albeit significantly less alkaline conditions are typically encountered). These conditions would then promote the transformation of the metastable zeolite to different structures.

It was discovered by Sievers et al. that the use of water at temperatures between 150–200°C has a negative effect on zeolite framework integrity when the water is in its condensed state [55]. The authors investigated a range of zeolite Y (FAU) structures obtained from Zeolyst, provided with the Si/Al ratio of 5, 14, and 41 and exposed them to hot liquid water under constant agitation at 150–200°C in an autoclave. The H2O (ml) : zeolite (g) ratio was 20 : 1. The system was pressurized by the autogenous pressure of water at these temperatures (5 and 17 bar, respectively). Concomitant to a loss of crystallinity as assessed by X-ray diffraction they also observed an increase in mesoporosity at the expense of micropores as well as a restructuring of the tetrahedral Al as it is ejected from the framework and is captured as a tetrahedral extra-framework species with a peak at 52 ppm instead of 60 ppm. Whereas steaming in controlled environments (at temperatures >250°C) led to an increase in hydrothermal stability (e.g. formation of USY by steaming zeolite Y, removing Al) and enhanced catalytic activity [56], the effect of hot liquid water was reversed. Instead of stabilizing the system, it led to an amorphization of the crystalline FAU framework exposed to hot liquid water as observed by X-ray diffraction. This was even more pronounced at higher Si/Al ratios indicating that the presence of Al is beneficial under the chosen conditions. In the case of steaming, the extent of dealumination is more severe at higher Al content. Consequently, they proposed that under the chosen conditions a hydroxide catalyzed hydrolysis of the Si–O–Si bonds rather than a proton catalyzed Si–O–Al dealumination takes place (Scheme 2).

Scheme 2 . Proposed method of framework hydrolysis under (1) steaming (or acidic) conditions leading primarily to dealumination and (2) alternatively in hot liquid water where Si−O−Si bonds are hydrolyzed by hydroxide anions. Reprinted with permission from J. Phys. Chem. C 2010, 114, 46, 19582−19595. Copyright (2019) American Chemical Society.

Larger concentrations of Al induce more negative framework charges, repelling the hydroxide anions and thus minimizing framework hydrolysis. The hydrolysis can seemingly be slowed by exchanging the protons with extra-framework species such as La or Al obtained in-situ by dealumination. Another important factor established by Sievers et al. was that ZSM-5 in contrast to zeolite Y showed no appreciable change in structural properties over the whole range of conditions investigated. This was attributed to a lower amount of structural defects and a higher energy of formation as well as higher density of T atoms [7]. This was based on conclusions drawn by Lutz et al. who also investigated high silica zeolite Y obtained by dealumination with SiCl4 and found the same correlation between Si/Al and relative crystallinity loss, associating it with the lower framework density in the case of FAU compared to MFI or MOR framework structures [57].

However, it should be mentioned that dealumination of FAU is not an ideal way to generate a high-silica variant. Depending on the mode of dealumination, through steaming, acid treatment, chelating, or SiCl4, variations in structural properties can be achieved. One of the important changes induced by the dealumination technique is the concentration of defects. While the preparation method for the FAU catalysts obtained from Zeolyst was not reported, it is entirely possible that the higher Si/Al samples had a higher concentration of defects. Similarly, the SiCl4 vapor dealumination method does remove Al by replacing it with Si, but this technique likely suffers from situations where an incomplete incorporation can also take place, similar to other silylation methods [58]. Nonetheless, Sels and co-workers also observed the stabilizing effect of Al on zeolite Y (USY Si/Al 2.6-30) in hot liquid water containing about 1 mM HCl (H2O (mL): zeolite (g) = 100 : 1) [59]. They were able to measure significant amount of Si leached from the zeolite after exposure to hot liquid water and the extent of amorphization increased with Si/Al, in line with previous results. Interestingly, they prepared their USY via steaming and acid washing, which is expected to introduce a significant defect concentration. However, they rationalized the increased resistance towards amorphization of low Si/Al samples by their increased amount of Al repelling the hydroxide. It should be noted, that both the use of La as an extra-framework species, or even the self-stabilizing behavior of USY described by Sels et al. is suboptimal as it reduces the amount of accessible active sites. Additionally, having a layer of poorly soluble extra-framework Al on the surface is beneficial but can also block access. Instead a novel concept was proposed by Resasco and co-workers [60]. This involved stabilizing the fragile FAU framework by selectively titrating the external crystallite surface with long-chain alkyl groups that act as hydrophobic barriers [60]. They used octadecyltrichlorosilcane (C18 hydrophobic tail) and successfully showed that the material’s crystallinity and microporosity was retained. Hot liquid water still generated some mesoporosity but to a lesser degree compared to the non-functionalized zeolite Y (CBV760 Zeolyst Si/Al 30). Interestingly, they were able to establish that it is the presence of liquid water that induces the structural damage, irrespective of the chemical potential [61]. As water vapor approaches its saturation pressure the chemical potential of water increases and thus in the case of steaming, conditions with more water vapor result in more severe dealumination. In the case of hot liquid water, however, structural damage was much more severe at conditions with more condensed water and seemed to be therefore independent of the chemical potential. The hydrophobization of the surface then prevents the condensation of water on and in the zeolite and thus staves off the degradation of the framework. However, they noted that at locations within the zeolite where small pockets of hydrophilic nature exist, such as those found in silanol defects and nests, water could condense at partial pressures below its saturation pressure and thus initiate the framework hydrolysis irrespective of the surface hydrophobization [61].

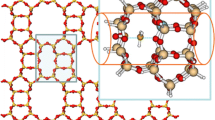

Extending the scope of these studies to other framework types besides FAU and MFI, Vjunov et al. were able to establish that in the BEA framework the stabilizing role of Al can also be observed [62]. They set out to investigate the origin of the stabilizing role of Al by probing commercially available H-BEA (Si/Al 12.5 and 150 obtained from Clariant) before and after exposure to hot liquid water (H2O (mL): zeolite (g) = 80 : 1). Following the atomistic changes of the Al in the framework using Al-EXAFS and 27Al MAS NMR they noted that the zeolite degrades via a selective hydrolysis of specific T-sites. This is owed in part due to the unique structural properties of the BEA zeolite, which crystallizes typically as a mixture of polymorph A (BEA) and polymorph B (BEB) (Fig. 1). A third polymorph also exists, polymorph C (BEC), which can be prepared selectively by using germanium instead of silicon as germanium promotes the formation of double-4-membered rings (D4R) which are an integral building unit of polymorph C [63]. However, the intergrowth of the BEA and BEB structure results in an area of enriched disorder, where a larger concentration of silanol groups can be expected [64]. Additionally, in BEA there are 9 distinct T-sites. Both properties are important in understanding the behavior of BEA in hot liquid water.

Representation of the three polymorphs of zeolite BEA. Most commercial samples are a mixture of polymorph A (a) and polymorph B (b) with the transition between the polymorphs being characterized by an intergrowth area enriched with silanol groups. Reprinted with permission from Chem. Mater. 2008, 20, 9, 3218–3223. Copyright (2019) American Chemical Society.

Using a combination of techniques (27Al MAS NMR, 29Si MAS NMR and Al-EXAFS) they could establish that the hydrolysis of the framework is initiated at Si–O–Si bridges located in the 4-membered rings [62]. At the same time, the Al tetrahedra act as stabilizing islands and do not undergo preferential hydrolysis. Nonetheless, given a sufficient degree of siloxane hydrolysis, the loss of Al will still take place. Due to the high solubility of Si at elevated temperatures the cleaved species will be dissolved in the entrained water and then deposit on the exterior of the crystallites as amorphous material, giving the impression of an overall amorphization [65, 66]. The authors also observed that HBEA150 (Si/Al 75) had withstood the hot liquid water treatment better than the sample with more Al (HBEA25), based on XRD assessment. This was attributed to a higher concentration of structural defects (e.g. SiOH) in HBEA25 determined from lower intensities in XRD patterns, which compensates any stabilizing effect Al could have on the integrity of the zeolite framework as was observed for zeolite Y.

Formation and Characterization of Internal Structural Defects

The work by Vjunov et al. [62] as well as Zapata et al. [61] had suggested that a crucial aspect for zeolite stability in hot liquid water was the presence and concentration of structural defect sites in the form of SiOH. We therefore devote an extended part of this review to their origins and characterization before investigating how defect sites and other factors are believed to impact zeolite stability in hot liquid water. These structural imperfections can be introduced in a variety of ways, ranging from post-synthetic treatments [56, 67, 68] as part of dealumination techniques such as steaming and acid leaching, as well as a consequence of the synthesis method [69, 70]. The latter is especially important for the synthesis of high-silica zeolites which have only small amounts of Al in the framework. In order to succeed with the synthesis of high-silica zeolites, organic structure directing agents (OSDA) such as tetraethylammonium hydroxide (TEA-OH) have to be used [71, 72]. To balance the positive charge of the ammonium, the negative framework charge originating from Al can be used. However, in the absence of this (at high Si/Al), the framework growing around the OSDA compensates the positive charge by breaking Si-O-Si bonds and generating a Si–O– bond. Upon removal of the OSDA at high temperatures (e.g. 550°C in N2/O2) the SiO– is converted to a hydroxyl group. In addition, the calcination of the OSDA can lead to the ejection of some framework Al, leaving behind more SiOH. As mentioned above, in the case of BEA, the intergrowth leads to additional defect formation [64]. If the T atom is completely removed, a group of four SiOH is left behind, which is called a silanol nest. It is possible for a SiOH nest to partially or completely condense during high temperature treatment [73]. In summary, we can describe several different types of SiOH groups, mainly isolated SiOH generated from point defects (e.g. balancing OSDA), SiOH nests (from T-atom removal during high temperature exposure) and additionally SiOH found on the external surfaces of zeolite crystallites. The concentration of the latter is affected by the particle size. To understand their influence on zeolite stability it is important to be able to differentiate between them as well as other nominal hydroxyl groups, such as bridging hydroxyls (i.e. Brønsted acid sites) and hydroxyl groups bonded to extra-framework Al species. Infrared spectroscopy is a powerful tool that allows us to observe the bands associated with the respective hydroxyl groups (Fig. 2). Bridging hydroxyl groups appear at 3610 cm–1, vibrations associated with EFAl species are seen at 3780 cm–1, [74] whereas SiOH groups can be seen either at 3750–3730 cm–1 in the case of isolated SiOH or around 3500 cm–1 for the SiOH nests [75, 76]. The reason for the shift towards lower wavenumbers in the case of SiOH nests lies in their ability to form H-bonds which affects the vibrational force constant [77]. The isolated SiOH could be further differentiated by external SiOH being at the upper end of the wavenumber spectrum, however, the peaks are usually not well resolved to make this distinction. Infrared spectroscopy follows the Lambert-Beer Law which dictates that the absorption (or transmission) is directly proportional to the path length (or the thickness of the wafer), the concentration of the respective species as well as its unique molecular absorption coefficient. In order to determine the concentration of the respective silanol groups it would then be required to first measure these absorption coefficients. In Fig. 2, the comparison between different samples of the same framework structure (BEA) is achieved by normalizing the spectra to the vibrational modes of the Si–O–Si bonds and it can be seen that the overall intensity in the SiOH region increases for samples with higher Si/Al. This is in line with what we described earlier, higher Si/Al having less Al available to balance the charge of the OSDA and thus creating more defect sites. Furthermore, the BEA75 sample with Si/Al 75 was a commercial zeolite sample, which could have been prepared by dealumination from a more Al-rich material.

Infrared spectrum of zeolite BEA showing the region significant to SiOH groups (3800–3200 cm–1) obtained in transmission mode. The spectra are normalized to the overtones of the lattice vibrational modes (2090–1740 cm–1, not shown). Right) 29Si MAS NMR spectra measured with cross-polarization enhancement, showing the Si environments close to hydrogen species (i.e. SiOH). Normalization to fully incorporated Si (Q4) allows semi-quantitave assessment of defect concentrations (i.e. Q3). Reprinted with permission from Chem. Mater. 2017, 29, 17, 7255–7262. Copyright (2019) American Chemical Society.

If the researcher is interested in quantifying SiOH in the zeolite sample, a different technique is available, namely 29Si MAS NMR. Here it is possible to differentiate between different Si environments such as Si surrounded by 4 O–Si groups (i.e. a fully tetrahedrally coordinated framework Si, Q4) and Si surrounded by only 3 O–Si groups and 1 O–Al or O–H group known as Q3. If only two O–Si groups surround a Si atom then the peak is denoted as Q2. This would be an example of either Al in very close proximity (next nearest neighbor) or a geminal SiOH [78, 79]. Different chemical environments in NMR are typically reflected by a shift in the peak position, which is also the case to differentiate these two species with 29Si MAS NMR. Q2 and Q3 signals appears at –90 and 103 ppm, respectively, while Q4 signals appear around –112 ppm. For certain BEA materials of very high crystallinity, the Q4 signal is split into several smaller peaks, indicative of the 9 distinct T-sites in BEA [80]. Another characteristic of 29Si MAS NMR is the relatively long relaxation time of 29Si which requires typically very long experiments (e.g. hours to days) to achieve a sufficient signal/noise ratio. However, it is possible to exploit the presence and quick relaxation times of protons which enhances the signal of nearby Si [81].81 This is known as cross-polarization technique and a typical spectrum for zeolite BEA of varying Si/Al is shown in Fig. 2. By normalizing the signal to the fully incorporated Q4 peak, it is possible to semi quantitatively assess the concentration of both isolated SiOH (Q3) and geminal SiOH (Q2).

In order to quantitatively assess the concentration of SiOH in a zeolitic material, a combination of 29Si MAS NMR and 27Al MAS NMR has to be used. The latter allows the differentiation between framework and extra-framework Al species in the zeolite material. It should be noted that the Q3 species in 29Si MAS NMR can constitute either a SiOH or an SiOAl species and the differentiation in most material is complicated due to the close chemical shift of the two species (–103 and –106 ppm, respectively) requiring careful deconvolution of the spectra [62]. Instead, knowing how much Al is present in the framework of the zeolite (i.e. Q3—SiOAl) would then only require a simple subtraction from the total Q3 peak area to determine the exact concentration of SiOH. Since the experimentally determined concentration does not differentiate between isolated SiOH, H-bonded SiOH nests and SiOH on the external surface, deconvolution of the IR spectra would allow to determine a relative contribution of each group (assuming that the individual molar extinction coefficients are the same for all types of SiOH) which was shown by Bregante et al. [38].

Impact of Structural Defects on Zeolite Stability

Next, the question remaining to be answered was what the impact of structural defects had on the stability of zeolites. Thus, Prodinger et al. studied the role of defects in a defect rich model system consisting of a boron substituted BEA zeolite (Si/B 12–16) [58]. B is similar to Al in many ways, creating a negative framework charge and subsequently acting as a Brønsted acid. However, compared to Al the acid strength is significantly weaker and another differentiation can be made on the hydrothermal stability of B [82]. While the element is incorporated as tetrahedral B during the synthesis (using sodium tetraborate as B-source) [83] the coordination sphere can be affected by the choice of the counter anion. Na+ and \({\text{NH}}_{4}^{ + }\) both have a stabilizing effect, however, in the presence of H+, the coordination changes to trigonal and this allows for a nucleophilic attack by water to remove the B from the framework completely. The role of the cations is important, as the procedure preparing a defective model system involved several high-temperature treatments (calcination of OSDA at 550°C, transformation of NH4 form into H-form at 450°C) and the stability of silanol nests under these conditions is questionable [73]. Instead, boron is removed and SiOH nests are created at mild temperatures of 50°C in water, as verified by the complete absence of signal in the 11B MAS NMR. The authors then exposed this highly defective material to hot liquid water (H2O (mL): zeolite (g) = 200 : 1) at 160°C for 48 hours. These conditions were quite severe and as has been proposed by Zapata et al. the amount of water in contact with the zeolite affects the severity of degradation. Thus, it can be safely assumed that under the investigated conditions, zeolite degradation had not reached a thermodynamic equilibrium given by the solubility of silica in hot liquid water. The aged material had lost a significant portion of its framework integrity evidenced by a loss of relative crystallinity and micropore volume. The treatment also introduced mesoporosity, with the shape of the hysteresis indicating open non-constrained pores. Most strikingly, the morphology of the particles also changed significantly after exposure to hot liquid water. Whereas the parent material crystallized as large (ca 1 µm) particles, the aged material was decorated with small fragments that retained crystallinity (Fig. 3). Among these crystalline fragments mesovoids were clearly visible in line with the hysteresis shape from N2 adsorption/desorption isotherms. Clearly, the hydrolysis of the framework led to the much more severe fragmentation than observed on Al-BEA previously [62].

Transmission electron micrographs of water treated defect rich BEA (left) and of BEA stabilized by post-synthetic silylation (right). The circles indicate the presence of mesovoids, the arrows the presence of elongated mesopores. The orange lines are meant to guide the eye to help visualize lattice diffractions. It is evident that the extent of stabilization was sufficient to retain the material’s morphological characteristics. Reprinted with permission from J. Am. Chem. Soc. 2016, 138, 13, 4408−4415. Copyright (2019) American Chemical Society.

When the authors then investigated the stability of Al-BEA samples (i.e. catalytically relevant material containing Brønsted acid sites) of varying Si/Al (12-75) they were able to establish a correlation that clearly established a connection between the defect concentration and the stability in hot liquid water [84]. BEA with higher Si/Al had a larger concentration of defects, as already shown in Fig. 2. Interestingly, based on the loss of relative crystallinity the defect rich B-BEA (after removal of B) experienced a less severe of framework degradation than the Al-BEA with Si/Al 75 (20% loss vs 33%, respectively). While the defect concentration for the B-BEA was significantly higher, the particle size of the Al-BEA (Si/Al 75, 200 nm) was only a fraction of that of B‑BEA (1 µm) thus suggesting that in addition to defect concentration particle size also plays a role. In fact, this is a parameter affecting zeolite stability in both steaming and hot liquid water conditions [19]. It is worth noting, that the Al-BEA with Si/Al 12 reported in the study by Prodinger et al. was obtained from a different supplier (Zeolyst) compared to the Al-BEA of the same chemical composition reported on by Vjunov et al. (Clariant) [62]. The latter completely lost its crystalline integrity after exposure to hot liquid water, whereas the Zeolyst sample only exhibited a 20% loss. While the Zeolyst sample had the lowest defect concentration of the Al-BEA series investigated by Prodinger et al. [84], the Clariant sample was clearly enriched in defect sites, as evidenced from X-ray diffraction pattern intensities [62]. These discrepancies should illustrate the importance of zeolite synthesis and how relying on zeolite materials provided by different suppliers can lead to erroneous conclusions. Instead, one is encouraged to synthesize their own nanoporous materials by following a synthesis procedure and adjusting the necessary parameters.

Stabilization Protocols to Counteract the Negative Effect of Defects

The conclusion that defect sites are the most crucial aspect affecting zeolite stability in hot liquid water was also drawn around the same time by Resasco et al. for the FAU framework [85]. In order to remediate the negative effect of defects several strategies are available. Resasco et al. have shown that the use of organosilane molecules can be very effective at increasing the hydrophobicity of the material [60, 61]. Along the same lines, Prodinger et al. treated their model defect system (deboronated BEA) with a small organosilane (trimethylchlorosilane—TMS-Cl) molecule that is able to selectively titrate silanol nests according to Scheme 3 [58]. The removal of defect sites could be verified with IR spectroscopy and 29Si MAS NMR. The post-synthetically modified material then underwent the same hydrothermal aging process as the defect-rich parent material and exhibited a superior stability.

Scheme 3 . Selective insertion of Si into SiOH nests achieved by titrating the SiOH with trimethylchlorosilane. The healing process can be followed with 29Si MAS NMR. Reprinted with permission from J. Am. Chem. Soc. 2016, 138, 13, 4408–4415. Copyright (2019) American Chemical Society.

The loss of relative crystallinity was negligible and while the water did cause some minor loss of microporosity, the morphology of the particles was retained, as evidenced by TEM (Fig. 3). Interestingly, elongated mesopores were observed with TEM, which was also supported by N2 physisorption hysteresis suggesting ink-bottle mesopores. This could point towards residual defect sites remaining in the material where water can still initiate siloxane hydrolysis slowly degrading the framework. The presence of silylation side products (i.e. incomplete condensation, or multiple titrations of the same SiOH nest) suggests that the treatment was not fully successful at reinserting a Si into the labile areas of the zeolite framework. Nonetheless, the method promised to provide sufficient stabilization for the material to withstand hot liquid water for extended periods of time. In the case of Al-BEA materials, the silylation was also successful at retarding the framework hydrolysis, however, it did so to a lesser degree for high-silica BEA (Si/Al 40 and 75) [84]. This was attributed to the protective effect of Al in the framework, which is inactive towards hydrolysis in hot liquid water. Additionally, it could also be rationalized that the origin of defects in high-silica BEA are due to the need to balance the OSDA which generates preferentially isolated SiOH or possibly vicinal SiOH. The titration with TMS-Cl would cap this SiOH, as well as possibly creating a new ≡SiFr–O–SiTMS–O–SiFr≡ bridge, however, in both cases it could be conceived that this strained environment would not create the original stability. In fact, some early, unpublished experiments in our group have shown that the healing of defects by heating the material to elevated temperatures (e.g. 650°C) did increase the relative crystallinity. It resulted in the condensation of SiOH groups, as well as the migration of Si [86]. However, the stability in hot liquid water did not improve which was hypothesized to be due to the lattice strain.

Instead, synthetic methods could be applied to reduce the extent of defect formation. This can be achieved by introducing fluoride anions to the synthesis gel, replacing the alkaline conditions generated by sodium hydroxide. Resasco et al. illustrated that the direct comparison of stability of Silicalite-1 in hot liquid water depended strongly on the synthesis approach [85]. In the presence of hydroxide anions, Silicalite-1 was prone to defect formation and completely lost its crystallinity in hot liquid water. In the case of the fluoride-mediated synthesis, the zeolite was able to retain 95% of its relative crystallinity after 6 h at 200°C, a remarkable result showing the influence of defect concentrations on stability.

Following Catalyst Deactivation in Aqueous Phase Reactions

From the above results, it is clear that the removal of defect sites is paramount to stabilizing zeolites for aqueous phase reactions. Vjunov et al. showed that the aged materials retained their site specific activity (turnover frequency), however, the deposition of amorphous silica dislodged during the framework hydrolysis blocks access to the sites and thus yields a lower concentration of Brønsted acid sites when probed with pyridine base [35]. It should also be noted that the individual turnover frequency was independent of the Si/Al ratio [35], implying that all sites are equally strong, which is in line with the results of Liu et al. who showed the active species within constrained zeolite pores in aqueous phase reactions to be hydrated hydronium ions (H2O)nH3O+ [32]. However, while the results indicated that the performance of zeolites is hampered by aging in hot liquid water, the conclusions do not accurately reflect on the behavior of the zeolite during catalysis. The observed lower initial rates (based on mass) were attributed to blocked sites; however, the blocking of the pores occurs primarily due to the cooling process after the aging in hot liquid water when amorphous material is deposited on the remaining crystallites. Instead, it would be necessary to probe the zeolite stability over the course of the catalyzed reaction. This necessitates performing the reaction over an extended period, allowing it to approach the equilibrium and then reducing the catalyst amount accordingly for the catalyst to completely deactivate before achieving equilibrium [87]. Establishing that the equilibrium conditions have not been reached would then allow one to deduce the zeolite lifetime based on the continuous change in the turnover frequency over time. Prodinger et al. used this methodology to investigate a series of Al containing BEA zeolites (Si/Al 12–75, see Fig. 2) on their performance in aqueous cyclohexanol dehydration [84]. Importantly, the amount of catalyst was only 30 mg which resulted in a H2O (mL) : zeolite (g) = 2600 : 1 representing the most severe conditions tested so far. As can be seen from Fig. 4, the use of 50 mg is enough to reach the equilibrium conversion (60%), 30 mg however, only yield 15% with the conversion leveling off within 5 hours. Evidently, this is related to the deactivation of the zeolite. However, when comparing the conversion-time curves for different Si/Al an interesting trend developed, namely, the higher the Si/Al the more molecules the zeolite was able to convert on a per site basis before deactivation (i.e. turnover number, TON). From this turnover number it was possible to calculate the lifetime and plotting it against the number of active sites showed the opposite trend to that observed in pure hot liquid water. Whereas pure hot liquid water affected samples with higher Si/Al more severely, owed to the higher defect concentration, when it came to converting cyclohexanol to cyclohexane, the lifetime of high silica BEA exceeded that of BEA with Si/Al 12 or 15, by hours, despite the lower concentration of defects in the latter [84]. Furthermore, removing part of the defects via silylation treatment was an effective means to stabilize zeolite degradation in pure hot liquid water. Through the lens of catalytic lifetime, however, it was less effective, in part due to partially titrating, blocking or removing the bridging hydroxyls.

(left) A conversion time plot showing the dehydration of aqueous cyclohexanol (0.33 M) at 170°C for BEA (Si/Al 12). Deactivation occurs within hours limiting the overall conversion to 15% (30 mg black line), far from the equilibrium (50 mg red line). Right) correlation between lifetime and Brønsted acid site concentration determined with Py-IR. The more acidic the zeolite, the shorter the catalytic lifetime. Reprinted with permission from S. Prodinger et al. Appl. Catal. B: 237 (2018) 996–1002 Copyright (2019) Elsevier.

The authors attributed the deactivation to a loss in the constrained environment, since non-constrained phosphoric acid showed a 20x lower activity than a corresponding zeolite with constrained hydronium ions.32 This was confirmed by scaling up the reaction and characterizing the remaining spent catalyst, which largely dissolved and shrunk in particle size. A clay impurity was detected with XRD. It became clear that the role of defects on zeolite stability was important but that the acidity of the zeolite was the more crucial in determining the catalytic lifetime. Thus, a set of nearly defect free zeolite BEA was synthesized in fluoride media with increasing Si/Al (15-230) and probed for their efficacy of converting aqueous cyclohexanol. Their lifetimes are shown in Fig. 4. The defect concentration, quantified via 29Si MAS NMR and 27Al MAS NMR, was lower for the Al-rich samples synthesized in fluoride media than the corresponding zeolite obtained in the hydroxide media; however, the catalytic lifetime was not improved. Only at high Si/Al was a noticeable positive effect observed between low-defect BEA (fluoride synthesis) and more defective BEA (hydroxide media). The lifetime enhancement was associated with a lower concentration of defects that minimize the presence of intraporous water at comparable Si/Al. This was probed via the selective liquid phase adsorption of cyclohexanol from an aqueous solution. Thus, the liquid water uptake could be determined. Remarkably, the uptake of liquid water was less strongly influenced by defect sites and was instead dominated by the concentration of Brønsted acid sites, or hydronium ions (Fig. 5). Considering the favored formation of hydrated hydronium ion complexes in zeolite pores [32, 37], the hydrophilic effect inferred from the acidity of the zeolite far outweighs any hydrophilicity associated with defect sites. This poses a challenge as an effective catalyst would have a high number of active sites to ensure an acceptable space-time yield. Performing these reactions with high Si/Al is not ideal and instead stabilization techniques for the Al-rich variants have to be probed. From the results, the concentration of water inside the pores needs to be minimized. Prodinger et al. successfully achieved this by selectively titrating the external crystallite surface with octadecyltrichlorosilane which had the effect that the material became super hydrophobic (contact angles >150°) [60, 77]. Thus, the hydrophobic barrier successfully extended the lifetime of the zeolite. However, more interestingly, it also appeared to affect the intrinsic activity of the hydronium ions, namely, increasing the TOF and thus the turnover number (i.e. total molecules converted per site until the catalyst deactivated). This was attributed to the hydrophobic barrier blocking part of the hydronium ions from diffusing into the non-constrained bulk water (and bulk water from entering the pores vice versa), and thus achieving a higher intrinsic activity than the hydrophilic counterpart. Surface hydrophobization did not change the defect concentration, yet the lifetime was increased showing the importance of minimizing contact of liquid water with extended zeolite surfaces.

(left) The measured intraporous water concentration as a function of Brønsted acidity and synthesis method. Hydroxide media invites the formation of defect which can bind additional water. Minimizing the defect concentration via fluoride media synthesis highlights the strong influence of Bronsted acidity on liquid water uptake. Right) Comparing the lifetime and turnover numbers for a surface hydrophobized BEA zeolite prepared in fluoride media (BEA 16-sil). The hydrophobization of the external surface affects the intrinsic activity of the pores, thus changing the lifetime and turnover number to different extent. Reprinted with permission from S. Prodinger et al. Appl. Catal. B: 237 (2018) 996–1002 Copyright (2019) Elsevier.

(left) Conversion time plots for the cyclohexanol dehydration reaction containing only small amounts of water (17.5 wt %) at 170°C. Core-shell structures of BEA (Si/Al 25) synthesized in fluoride media are tested. The legend denotes the amount of siliceous shell material (purely siliceous BEA) added in wt %. (right) Normalizing the initial rates to the reduced number of active sites shows an increase in TOF initially, before it drops at higher shell content.

We then attempted to expand on this concept of preferential diffusion limitations by imitating cell membranes. To ensure that nutrients are able to access the cells, selective ion channels exist in their membranes that allow the selective diffusion of some but not other atoms. Similarly, we envisioned that a core-shell structure consisting of a hydrophobic shell surrounding a hydrophilic core would allow us to extend the zeolite lifetime while simultaneously using a highly active Al-rich BEA zeolite. This was achieved by first preparing a solid gel of Al-BEA in fluoride medium (H2O/SiO2 7) which then underwent partial hydrothermal synthesis. As soon as sampling of the gel showed the successful formation of BEA phase (as indicated by XRD), a second gel of the same composition but without Al was prepared and added to the same reactor containing the partially formed Al-BEA (<10 wt % gel added). The synthesis was continued for a specific time resulting in the growth of Si-BEA on top of the already formed Al-BEA. After calcination removed the template, the catalytically active material was tested for cyclohexanol dehydration. Albeit the conversion appeared to be lower, when normalizing to the reduced number of active sites a slight increase in turnover frequency was observed. However, this was only successful for small amounts of Si-BEA added, as increasing Si-BEA wt % led to a drop in the TOF. We attributed this to an ineffective synthesis procedure that resulted in the preferential growth of siliceous BEA next to crystals of Al-BEA and thus forming an aggregated mixture of Si-BEA and Al-BEA without the successful creation of a core-shell system. This is evident from He ion micrographs, where large Al-BEA bipyramids are seen next to smaller crystallites associated with Si-BEA. More studies need to be performed on optimizing the synthesis as well as establishing beyond doubt the effectiveness of the hydrophobic barrier on activity and lifetime of the zeolite. Recently, successful core-shell structures have also been reported for the MFI structure consisting of silicalite-1 shells and an ZSM-5 core [88–90]. This was achieved by using a dry-gel of ZSM-5 and then performing an incipient wetness impregnation with TPAOH and TEOS before performing a dry-gel synthesis. A very thin (<20 nm) layer was created, which was confirmed to be Al-free using an XPS technique. These materials were mainly investigated for the methanol-to-hydrocarbon process in the gas phase [89]; however, it was also reported to exhibit superior lifetime when exposed to hot liquid water, when compared to a conventional ZSM-5 [88].

Metallo-Zeolite Stability in the Presence of Hot Liquid Water

To date there exist only a few of studies investigating the stability of Lewis acidic zeolites. Often these are performed at 100% conversion or thermodynamic equilibrium and the recyclability of the catalyst is tested in a batch reactor. Unfortunately, this does not allow any insight into the deactivation behavior as the chosen catalyst loading might be too high and since the deactivation process is a kinetic step, it should be investigated in a kinetic regime as well [87].

Generally, Lewis-acidic zeolites are considered more stable compared to their aluminosilicate counterparts, mainly due to the high degree of hydrophobicity preventing the direct exposure of the large internal surface area to water. In the case of the Lewis-acidic zeolites stability is typically differentiated between reversible and permanent catalyst deactivation. Formation of carbonaceous species and the binding of solvent molecules and/or undesired side products to the active site can be reversed by exposing the zeolite to elevated temperatures.

Metal leaching or the transformation of the framework structure, on the other hand, cannot be reversed and are considered more detrimental to zeolite performance. It can be generally accepted that the hydrophobic nature of the metallo-zeolites and formation of large crystallites and particles due to the low degree of nucleation in fluoride media is beneficial for zeolite stability in the context of phase transformations. However, it has not been studied extensively whether metal leaching is a severe problem which can become crucial as many of the potential oxygenated reactants have chelating capabilities and could extract the metal from the zeolite. And even if metal leaching has been shown to not occur by probing catalyst recyclability, the continuous exposure to reactant and solvent molecules can lead to the restructuring of the metal sites over time. This was shown in the case of glucose isomerization over Sn-BEA where a hydrophobic form of the zeolite was transformed into an inactive hydrophilic version over time [91]. This transformation was induced by the exposure to hot liquid water over extended periods, hydrolyzing part of the Si–O–Si framework and thus generating SiOH. While this initially led to an increase in turnover rates, due to an enthalpic stabilization of the transition state due to the presence of molecular water, an increasing concentration of SiOH had a negative effect on the glucose isomerization rate [91]. This was due to the SiOH concentration reaching a critical value where the stabilization of extended hydrogen bonded networks was facilitated [92].

To reduce the extent of zeolite deactivation in these metallosilicates the use of co-solvents such as ethanol in addition to water has been found to be beneficial to suppress the formation of humins (i.e. carbonaceous deposits) [93]. The introduction of mesopores, generating a hierarchical framework can also alleviate the formation of carbonaceous species in the micropores containing the active sites [94]. Additionally, limiting the diffusion of water into the zeolite pores will also prevent the formation of silanols as well as hydrolysis of metal sites. This can be achieved by depositing hydrophobic modification on the external crystallite surface.

CONCLUSION

Let us now summarize some of the important factors affecting zeolite stability in hot liquid water and aqueous phase reactions.

Defect sites, in the form of isolated SiOH, SiOH nests, external SiOH need to be minimized as they provide an access point for the siloxane hydrolysis that will lead to framework disintegration [58, 85]. Minimization can be achieved through post-synthetic titration [58], fluoride-mediated synthesis [77] or in-situ generation of extra-framework Al species [22] that can block the SiOH groups. Undesirable effect of external SiOH can be minimized by synthesizing large particle sizes. In a perfect system absent any SiOH no Si–O–Si cleavage should occur. In respect to Lewis acid zeolites, Bregante et al. as well as Bukowski et al. have recently shown how SiOH can stabilize extended water structure networks [38, 92]. While these aided in the catalysis in confined spaces, the impact of these on the stability of the Ti-BEA and Sn-BEA remain to be studied. A precise control of the nature and number of defect sites is likely needed in order to prevent the loss of the active site over time.

Intraporous water concentration needs to be minimized as the amount of water directly influences the extent of framework hydrolysis and leaching of metal sites in Lewis acidic zeolites. This can be achieved synthetically by increasing the Si/Al or post-synthetically by introducing hydrophobic barriers on the external surface area. In the case of Lewis acidic zeolites this can also be minimized by the curing of internal defects [52], however, in the case of Brønsted acid zeolites the hydrophilicity associated with the acid sites is more significant than the hydrophilicity associated with defect sites and thus, minimizing defect concentrations has only a marginal effect on intraporous water. It is also noteworthy to mention the effect an organic co-solvent can have as shown for the case of cyclohexanol dehydration which occupied significantly more space in zeolite BEA thus minimizing the intraporous void left for water to fill [84].

The framework type also appears to be significant, with FAU < BEA < MFI in terms of zeolite stability in hot liquid water. It would suggest that the density of the framework plays a role or the size of the pore environment, and although we cannot fully exclude this, it is also likely that the main factor is associated with defect concentrations. For example, FAU can be formed at low Si/Al (e.g. 2.5) and withstand hot liquid water yet dealumination will lead to the framework becoming unstable. At the same time, dealumination with SiCl4, if done correctly, can lead to a virtually stable system with very high Si/Al [85]. Previous literature suggested FAU to become labile at high Si/Al, and these discrepancies are clearly a result of the dealumination technique [55]. Similarly, for BEA the challenge remains to create a pure form of either polymorph A, B, or C as this would prevent the formation of intergrowth areas where the stacking faults lead to an increased concentration of defect sites [64]. However, it should be noted that polymorph C is formed in the presence of Ge and contains double-4-membered (D4R) units (Fig. 1) which are energetically unfavorable [63, 95]. Therefore, the hydrothermal stability of polymorph C is predicted to be poor. This leaves MFI as a potential stable candidate; and indeed, it exhibits no adverse effect from being exposed to hot liquid water. While there are so far no studies on its catalytic lifetime, the higher intrinsic activity achieved by the enthalpic gains of the smaller pore environment make it a suitable candidate for the conversion of cyclohexanol.34 For larger molecules such as sugar molecules, however, it is unsuitable.

Yet, there have been reports that depending on the reaction conditions MFI also becomes labile. NaCl solutions are able to induce dealumination (i.e. Si–O–Al hydrolysis) which most interestingly removes fragments of alumina species that can catalyze the dehydration of glucose [96]. On the other hand the concentration of NaCl had no impact on FAU zeolite if the pH was adjusted to 3, which can likely be attributed a lower concentration of OH- anions compared to pH 7 [97]. The authors also observed an amorphous layer during the zeolite transformation which they proposed closes the interior of the zeolite towards further attack. Similarly, reports have shown that higher temperatures (>200°C), while more severe on the rate of hydrolysis, can lead to self-stabilization due to dealumination taking place [98, 99]. While most biomass valorization processes will likely take place in the liquid phase at temperatures <200°C, the role of self-stabilization through dealumination observed at high temperatures can likely be neglected.

Lastly, an interesting approach has recently been published by Liu and co-workers establishing that H-MCM49 (MCM-22 framework type) exposed to hot liquid water for nearly 2500 h experiences a dissolution equilibrium when the dissolution of H‑MCM49 is halted and instead transformed into kaolinite [100]. As the hydrolysis of Si-O-Si bridges releases Si into the aqueous solution, the solubility of Si limits the extent to which the framework can be hydrolyzed. By introducing amorphous Si into the feed and pre-saturating the solution with Si, the equilibrium would be shifted away from siloxane hydrolysis. Liu et al. even suggested that growth of MCM-49 could take place provided enough Si is present [100].

Liu et al. touched on an important point that has been observed by several other research groups as well. The stability in hot liquid water is essentially nothing more than conditions reminiscent of hydrothermal synthesis [22, 61]. The behavior of Si–O–Si hydrolysis resembles the alkaline depolymerization processes of Si sources during the initial synthesis step. However, this close link also implies and reminds us of the metastable nature of zeolites and how the ultimate stabilization technique would require us to change the thermodynamic state of zeolites. Thus, developing in situ and operando analytical tools that allow us to follow the formation [101, 102] of zeolites as well as their deactivation and degradation will help us gain additional insight into the continuously changing environment of zeolite catalysts during aqueous phase reactions.

Change history

22 September 2021

An Erratum to this paper has been published: https://doi.org/10.1134/S0965544121090176

REFERENCES

A. Corma, Chem. Rev. 95, 559 (1995).

A. Primo, H. Garcia, Chem. Soc. Rev. 43, 7548 (2014).

B. Yilmaz, U. Müller, Top. Catal. 52, 888 (2009).

S. J. DeCanio, J. R. Sohn, P. O. Fritz, J. H. Lunsford, J. Catal. 101, 132 (1986).

G. J. Cruciani, Phys. Chem. Solids 67, 1973 (2006).

P. M. Piccione, C. Laberty, S. Yang, M. A. Camblor, A. Navrotsky, M. E. Davis, J. Phys. Chem. B 104, 10001 (2002).

I. Petrovic, A. Navrotsky, M. E. Davis, S.I. Zones, Chem. Mater. 5, 1805 (1993).

A. Corma, M. E. Davis, ChemPhysChem 5, 304 (2004).

D. R. Lide, G. Baysinger, CRC Handbook of Chemistry and Physics: A Ready-Reference Book of Chemical and Physical Data. Choice Rev. Online 41, 41 (2004).

Y. Tao, H. Kanoh, L. Abrams, K. Kaneko, Chem. Rev. 106, 896 (2006).

T. Fjermestad, S. Svelle, O. Swang, J. Phys. Chem. C 117, 13442 (2013).

E. Bourgeat-Lami, P. Massiani, F. Di Renzo, P. Espiau, F. Fajula, T. Des Courières, Appl. Catal. 72, 139 (1991).

M. C. Silaghi, C. Chizallet, E. Petracovschi, T. Kerber, J. Sauer, P. Raybaud, ACS Catal. 5, 11 (2015).

R. A. Beyerlein, G. B. McVicker, L. N. Yacullo, J. J. Ziemiak, J. Phys. Chem. 92, 1967 (1988).

F. Schüßler, E. A. Pidko, R. Kolvenbach, C. Sievers, E. J. M. Hensen, R.A. Van Santen, J.A. Lercher, J. Phys. Chem. C 115, 21763 (2011).

F. E. Trigueiro, D. F. J. Monteiro, F. M. Z. Zotin, E.Falabella Sousa-Aguiar, J. Alloys Compd. 344, 337 (2002).

Y. Cui, Y. Wang, D. Mei, E. D. Walter, N. M. Washton, J. D. Holladay, Y. Wang, J. Szanyi, C. H. F. Peden, F. Gao, J. Catal. 378, 363 (2019).

F. Gao, Y. Wang, N. M. Washton, M. Kollár, J. Szanyi, C. H. F. Peden, ACS Catal. 5, 6780 (2015).

S. Prodinger, M.A. Derewinski, Y. Wang, N. M. Washton, E. D. Walter, J. Szanyi, F. Gao, Y. Wang, C. H. F. Peden, Appl. Catal. B Environ. 201, 461 (2017).

G. W. Huber, S. Iborra, A. Corma, Chem. Rev. 106, 4044 (2006).

A. Corma, S. Iborra, A. Velty, Chem. Rev. 107, 2411 (2007).

T. Ennaert, J. Van Aelst, J. Dijkmans, R. De Clercq, W. Schutyser, M. Dusselier, D. Verboekend, B. F. Sels, Chem. Soc. Rev. 45, 584 (2016).

C. Zhao and J. A. Lercher, Angew. Chemie−Int. Ed. 51, 5935 (2012).

D. E. Resasco, B. Wang, D. Sabatini, Nat. Catal. 1, 731 (2018).

J. C. Serrano-Ruiz, R. Luque, A. Sepúlveda-Escribano, Chem. Soc. Rev. 40, 5266 (2011).

S. Czernik, A. V. Bridgwater, Energy and Fuels 18, 590 (2004).

T. Keijer, V. Bakker, J. C. Slootweg, Nat. Chem. 11, 190 (2019).

C. Zhao, D. M. Camaioni, J. A. Lercher, J. Catal. 288, 92 (2012).

C. Zhao, W. Song, J. A. Lercher, ACS Catal. 2, 2714 (2012).

C. Zhao, Y. Kou, A. A. Lemonidou, X. Li, J. A. Lercher, Chem. Commun. 46, 412 (2010).

A. Vjunov, M. Y. Hu, J. Feng, D. M. Camaioni, D. Mei, J. Z. Hu, C. Zhao, J. A. Lercher, Angew. Chemie - Int. Ed. 53, 479 (2014).

Y. Liu, A. Vjunov, H. Shi, S. Eckstein, D. M. Camaioni, D. Mei, E. Baráth, J. A. Lercher, Nat. Commun. 8, 2 (2017).

A. Vjunov, J. L. Fulton, T. Huthwelker, S. Pin, D. Mei, G. K. Schenter, N. Govind, D. M. Camaioni, J. Z. Hu, J. A. Lercher, J. Am. Chem. Soc. 136, 8296 (2014).

H. Shi, S. Eckstein, A. Vjunov, D.M. Camaioni, J. A. Lercher, Nat. Commun. 8, 1 (2017).

A. Vjunov, M. A. Derewinski, J. L. Fulton, D. M. Camaioni, J. A. Lercher, J. Am. Chem. Soc. 137, 10374 (2015).

D. Mei, J.A. Lercher, J. Phys. Chem. C 123, 25255 (2019).

S. Eckstein, P. H. Hintermeier, R. Zhao, E. Baráth, H. Shi, Y. Liu, J. Lercher, Angew. Chemie. (2019).

D. T. Bregante, A. M. Johnson, A. Y. Patel, E. Z. Ayla, M. J. Cordon, B. C. Bukowski, J. Greeley, R. Gounder, D. W. J. Flaherty, Am. Chem. Soc. 141, 7302 (2019).

M. Taramasso, G. Perego, B. Notari, US Patent No. 7081237 (1983).

A. Corma, S. Valencia, US Patent No. 5968463 (1999).

Y. Zhu, K.L. Fow, G.K. Chuah, S. Jaenicke, Chem.-A Eur. J. 13, 541 (2007).

E. Mahmoud, J. Yu, R. J. Gorte, R. F. Lobo, ACS Catal. 5, 6946 (2015).

J. D. Lewis, S. Van de Vyver, A. J. Crisci, W. R. Gunther, V. K. Michaelis, R. G. Griffin, Y. Román-Leshkov, ChemSusChem 7, 2255 (2014).

A. Corma, F. X. Llabrés I Xamena, C. Prestipino, M. Renz, S. Valencia, J. Phys. Chem. C 113, 11306 (2009).

C. Perego, A. Carati, P. Ingallina, M. A. Mantegazza, G. Bellussi, Appl. Catal. A Gen. 221, 63 (2001).

A. Corma, L. T. Nemeth, M. Renz, S. Valencia, Nature 412, 423 (2001).

A. Corma, M. E. Domine, L. Nemeth, S. Valencia, J. Am. Chem. Soc. 124, 3194 (2002).

M. Moliner, Dalt. Trans. 43, 4197 (2014).

H. Y. Luo, J. D. Lewis, Y. Román-Leshkov, Annu. Rev. Chem. Biomol. Eng. 7, 663 (2016).

P. Y. Dapsens, C. Mondelli, J. Pérez-Ramírez, Chem. Soc. Rev. 44, 7025 (2015).

V. Eroshenko, R. C. Regis, M. Soulard, J. Patarin, C. R. Physique 3, 111 (2002).

R. Gounder, M. E. Davis, AIChE J. 59, 3349 (2013).

Y. Román-Leshkov and M. E. Davis, ACS Catal. 1, 1566 (2011).

M. Boronat, A. Corma, M. Renz, J. Phys. Chem. B 110, 21168 (2006).

R. M. Ravenelle, F. Schüssler, A. Damico, N. Danilina, J. A. Van Bokhoven, J. A. Lercher, C. W. Jones, C. Sievers, J. Phys. Chem. C 114, 19582 (2010).

R. A. Beyerlein, C. Choi-Feng, J. B. Hall, B. J. Huggins, G. Ray, J. Top. Catal. 4, 27 (1997).

W. Lutz, H. Toufar, R. Kurzhals, M. Suckow, Adsorption 11, 405 (2005).

S. Prodinger, M. A. Derewinski, A. Vjunov, S. D. Burton, I. Arslan, J. A. Lercher, J. Am. Chem. Soc. 138, 4408 (2016).

T. Ennaert, J. Geboers, E. Gobechiya, C. M. Courtin, M. Kurttepeli, K. Houthoofd, C. E. A. Kirschhock, P. C. M. M. Magusin, S. Bals, P. A. Jacobs, et al. ACS Catal. 5, 754 (2015).

P. A. Zapata, J. Faria, M. P. Ruiz, R. E. Jentoft, D. E. Resasco, J. Am. Chem. Soc. 134, 8570 (2012).

P. A. Zapata, Y. Huang, M. A. Gonzalez-Borja, D. E. Resasco, J. Catal. 308, 82 (2013).

A. Vjunov, J. L. Fulton, D. M. Camaioni, J. Z. Hu, S. D. Burton, I. Arslan, J. A. Lercher, Chem. Mater. 27, 3533 (2015).

A. Corma, M. T. Navarro, F. Rey, J. Rius, S. Valencia, Angew. Chemie - Int. Ed. 40, 2277 (2001).

P. A. Wright, W. Z. Zhou, J. Perez-Pariente, M. J. Arranz, Am. Chem. Soc. 127, 494 (2005).

G. B. Alexander, W. M. Heston, R.K. Iler, J. Phys. Chem. 58, 453 (1954). 30

P. M. Dove, N. Han, A. F. Wallace, J. J. De Yoreo, Proc. Natl. Acad. Sci. 105, 9903 (2008).

A. Gola, B. Rebours, E. Milazzo, J. Lynch, E. Benazzi, S. Lacombe, L. Delevoye, C. Fernandez, Microporous Mesoporous Mater. 40, 73 (2000).

S. M. Maier, A. Jentys, J. A. Lercher, J. Phys. Chem. C 115, 8005 (2011).

M. A. Camblor, L. A. Villaescusa, M. Díaz-Cabañas, J. Top. Catal. 9, 59 (1999).

M. A. Camblor, A. Corma, S. Valencia, Microporous Mesoporous Mater. 25, 59 (1998).

N. D. Hould, A. Foster, R. F. Lobo, Microporous Mesoporous Mater. 142, 104 (2011).

R .F. Lobo, S. I. Zones, M. E. Davis, J. Inclusion Phenom. Mol. Recognit. Chem. 21, 47 (1995).

E. Senderov, I. Halasz, D. H. Olson, Microporous Mesoporous Mater. 186, 94 (2014).

I. Kiricsi, C. Flego, G. Pazzuconi, W. O. Parker, R. Millini, C. Perego, G. Bellussi, J. Phys. Chem. 98, 4627 (1994).

G. L. Woolery, L .B. Alemany, R. M. Dessau, A. W. Chester, Zeolites 6, 14 (1986).

R. M. Dessau, K. D. Schmitt, G. T. Kerr, G. L. Woolery, L. B. Alemany, J. Catal. 104, 484 (1987).

S. Prodinger, H. Shi, H. Wang, M. A. Derewinski, J. A. Lercher, Appl. Catal. B Environ. 237, 996 (2018).

T. Takei, K. Kato, A. Meguro M. Chikazawa, Eng. Asp. 150, 77 (1999).

Z. Wang, Y. Jiang, Y. Zhang, J. Shi, C. Stampfl, M. Hunger, J. Huang, Ind. Eng. Chem. Res. 57, 5550 (2018).

M. A. Camblor, A. Corma, S. Valencia, J. Mater. Chem. 8, 2137 (1998).

D. W. Sindorf, G. E. Maciel, J. Phys. Chem. 86, 5208 (1982).

H. Koller, C. Fild, R. F. Lobo, Mesoporous Mater. 79, 215 (2005).

M. Derewinski, F. Di Renzo, P. Espiau, F. Fajula, M. A. Nicolle, Stud. Surf. Sci. Catal. 69, 127 (1991).

S. Prodinger, H. Shi, S. Eckstein, J. Z. Hu, M. V. Olarte, D. M. Camaioni, M. A. Derewinski, J. A. Lercher, Chem. Mater. 29, 7255 (2017).

L. Zhang, K. Chen, B. Chen, J. L. White, D.E. Resasco, J. Am. Chem. Soc. 137, 11810 (2015).

G. Engelhardt, U. Lohse, A. Samoson, M. Mägi, M. Tarmak, and E. Lippmaa, Zeolites 2, 59 (1982).

S. L. Scott, ACS Catal. 8, 8597 (2018).

M. Li, Y. Hu, Y. Fang, T. Tan, Catal. Today 339, 312 (2020).

F. Goodarzi, I. P. Herrero, G. N. Kalantzopoulos, S. Svelle, A. Lazzarini, P. Beato, U. Olsbye, S. Kegnæs, Microporous Mesoporous Mater. 292, 109730 (2020).

A. Eschenbacher, F. Goodarzi, A. Saraeian, S. Kegnæs, B. H. Shanks, A.D. Jensen, J. Anal. Appl. Pyrolysis 104712 (2019).

M. J. Cordon, J. N. Hall, J. W. Harris, J. S. Bates, S. J. Hwang, R. Gounder, Catal. Sci. Technol. 9, 1654 (2019).

B.C. Bukowski, J.S. Bates, R. Gounder, J. Greeley, Angew. Chemie - Int. Ed. 58, 16422 (2019).

W. N. P. van der Graaff, C. H. L. Tempelman, F. C. Hendriks, J. Ruiz-Martinez, S. Bals, B. M. Weckhuysen, E. A. Pidko, E. J. M. Hensen, Appl. Catal. A Gen. 564, 113 (2018).

B. Tang, W. Dai, X. Sun, G. Wu, N. Guan, M. Hunger, L. Li, Green Chem. 17, 1744 (2015).

P. Eliášová, M. Opanasenko, P. S. Wheatley, M. Shamzhy, M. Mazur, P. Nachtigall, W. J. Roth,; R. E. Morris, J. Čejka, Chem. Soc. Rev. 44, 7177 (2015).

D. W. Gardner, J. Huo, T.C. Hoff, R. L. Johnson, B. H. Shanks, J. P. Tessonnier, ACS Catal. 5, 4418 (2015).

C. Buttersack, A. König, R. Gläser, Microporous Mesoporous Mater. 281, 148 (2019).

A. R. Maag, G. A. Tompsett, J. Tam, C. A. Ang, G. Azimi, A. D. Carl, X. Huang, L. J. Smith, R.L. Grimm, J. Q. Bond, et al. Phys. Chem. Chem. Phys. 21, 17880 (2019).

A. K. Jamil, O. Muraza, R. Osuga, E. N. Shafei, K. H. Choi, Z. H. Yamani, A. Somali, T. Yokoi, J. Phys. Chem. C 120, 22918 (2016).

X. Sun, Y. Wang, Y. He, Y. Yang, S. Xu, S. Zhu, M. Yang, Z. Liu, Ind. Eng. Chem. Res. 58, 9339 (2019).

I. I. Ivanova, Y. G. Kolyagin, I. A. Kasyanov, A. V. Yakimov, T. O. Bok, D. N. Zarubin, Angew. Chemie-Int. Ed. 56, 15344 (2017).

S. Prodinger, A. Vjunov, J. Z. Hu, J. L. Fulton, D. M. Camaioni, M. A. Derewinski, J. A. Lercher, Chem. Mater. 30, 888 (2018).

ACKNOWLEDGMENTS

The authors would like to thank J.A. Lercher for his continued support and discussion on the topic of zeolite stability, the various co-workers who have contributed to these efforts over the years including but not limited to Drs. A. Vjunov, H. Shi, S. Eckstein, J. Hu, J. Fulton and D.M. Camaioni. S.P. acknowledges support by Catalysis Center for Energy Innovation, an Energy Frontier Research Center funded by the U.S. Department of Energy, Office of Science, Office of Basic Energy Sciences (under Award no. DE-SC0001004) as well as by the RAPID manufacturing institute, supported by the Department of Energy (DOE) Advanced manufacturing Office (AMO), award number DE-EE000788-7.6. M.A.D. acknowledges support by Pacific Northwest National Laboratory and Jerzy Haber Institute of Catalysis and Surface Chemistry, PAS under Joint Appointment Program.

Author information

Authors and Affiliations

Corresponding authors

Additional information

This paper is dedicated to Prof. Boris Romanovsky, an outstanding scientist, excellent teacher and big friend.

The original online version of this article was revised: due to a retrospective Open Access order.

Rights and permissions