Abstract

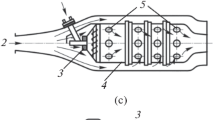

This article is the third in a planned series of articles devoted to the experience gained around the world in constructing low-emission combustion chambers for on-land large-capacity (above 250 MW) gas-turbine units (GTUs). The aim of this study is to generalize and analyze the ways in which different designers apply the fuel flow and combustion arrangement principles and the fuel feed control methods. The considered here GT24 and GT26 (GT24/26) gas-turbine units generating electric power at the 60 and 50 Hz frequencies, respectively, are fitted with burners of identical designs. Designed by ABB, these GTUs were previously manufactured by Alstom, and now they are produced by Ansaldo Energia. The efficiency of these GTUs reaches 41% at the 354 MW power output during operation in the simple cycle and 60.5% at the 505MW power output during operation in the combined cycle. Both GTUs comply with all requirements for harmful emissions. The compression ratio is equal to 35. In this article, a system is considered for two-stage fuel combustion in two sequentially arranged low-emission combustion chambers, one of which is placed upstream of the high-pressure turbine (CC1) and the other upstream of the low-pressure turbine (CC2). The article places the main focus on the CC2, which operates with a decreased content of oxygen in the oxidizer supplied to the burner inlets. The original designs of vortex generators and nozzles placed in the flow of hot combustion products going out from the high-pressure turbine are described in detail. The article also presents an original CC2 front plate cooling system, due to which a significantly smaller amount of air fed for cooling has been reached. The article also presents the pressure damping devices incorporated in the chamber, the use of which made it possible to obtain a significantly wider range of CC loads at which its low-emission operation is ensured. The fuel feed adjustment principles and the combustion control methods implemented in the low-emission combustion chambers of this GTU are of interest from the scientific and practical points of view.

Similar content being viewed by others

References

“Simple cycle GTW design ratings; combined cycle GTW design ratings,” Gas Turbine World 47 (1), GTW SPECS (2017). http://www.gasturbineworld.com

K. M. Düsing, A. Ciani, U. Benz, A. Eroglu, and K. Knapp, “Development of GT24 and GT26 (upgrades 2011) reheat combustors, achieving reduced emissions and increased fuel flexibility,” in Proc. ASME Turbo Expo 2013: Turbine Tech. Conf. and Exposition (GT2013), San Antonio, TX, June 3–7, 2013 (ASME, New York, 2013), paper no. GT2013-95437.

F. Joos, Ph. Brunner, B. Schulte-Werning, and K. Syed, “Development of the sequential combustion system for the ABB GT24/GT26 gas turbine family,” in Proc. ASME 1996 Int. Gas Turbine and Aeroengine Congr. and Exhibition, Birmingham, June 10–13, 1996 (ASME, New York, 1996), paper no. 96-GT-315. http://www.asme.org/about-asme/terms-of-use.

C. O. Paschereit, B. Schuermans, and D. Buchey, “Combustion process optimization using evolutionary algorithm,” in Proc. ASME Turbo Expo 2003, Atlanta, GA, June 16–19, 2003 (ASME, New York, 2003), paper no. GT2003-38393.

M. Hiddeman and P. Marx, “Operating experience with the latest upgrade of Alstom’s sequential combustion GT26 gas turbine,” in Proc. ASME Turbo Expo 2010: Power for Land, Sea and Air (GT2010), Glasgow, June 14–18, 2010, paper no. GT2010-23571.

M. Zajadatz, “Development and design of Alstom’s staged fuel gas injection EV burner for NOx reduction,” in Proc. ASME Turbo Expo 2007, Montreal, Canada, May 14–17, 2007 (ASME, New York, 2007), paper no. GT2007-27730.

K. M. Düsing, A. Ciani, and A. Eroglu, “Effect of mixing quality on NOx emissions in reheat combustion of GT24 & GT26 engines,” in Proc. ASME Turbo Expo 2011 (GT2011), Vancouver, Canada, June 6–10, 2011 (ASME, New York, 2011), paper no. GT2011-45676.

A. Ciani, A. Eroglu, F. Güthe, and B. Paikert, “Fullscale atmospheric tests of sequential combustion,” in Proc. ASME Turbo Expo 2010: Power for Land, Sea and Air (GT2010), Glasgow, June 14–18, 2010, paper no. GT2010-22891.

P. Flohr and A. Eroglu, “Combustor design for low emissions and long lifetime requirements,” in Proc. ASME Turbo Expo 2009: Power for Land, Sea and Air (GT2009), Orlando, FL, June 8–12, 2009 (ASME, New York, 2009), GT2009-59540.

T. Wind, F. Güthe, and K. Syed, “Co-firing of hydrogen and natural gases in lean premixed conventional and reheat burners (Alstom GT26),” in Proc. ASME Turbo Expo 2014: Turbine Tech. Conf. and Exposition (GT2014), Düsseldorf, Germany, June 16–20, 2014 (ASME, New York, 2014), paper no. GT2014-25813.

R. Kulkarni, B. Bunkute, F. Biagioli, M. Duesing, and W. Polifke, “Large eddy simulation of Alstom’s reheat combustor using tabulated chemistry and stochastic combustion model,” in Proc. ASME Turbo Expo 2014: Turbine Tech. Conf. and Exposition (GT2014), Düsseldorf, Germany, June 16–20, 2014 (ASME, New York, 2014), paper no. GT2014-26053.

S. Zahirovic and K. Knapp, “Ansaldo GT26 sequential combustor performance in long-term commercial operation,” in Proc. ASME Turbo Expo 2017: Turbomachinery Tech. Conf. and Exposition (GT2017), Charlotte, June 26–30, 2017 (ASME, New York, 2017), paper no. GT2017-64289.

G. Fruechtel, A. Pesenti, and P. Traverso, “The path forward to more efficient combustion in very large GT,” in Proc. Hele Conf. Ansaldo Combustion, Sept. 27, 2016 (Ansaldo, 2016).

B. Schuermans, M. Bothien, M. Maurer, and B. Bunkute, “Combined acoustic damping-cooling system for operational flexibility of GT26/GT24 reheat combustors,” in Proc. ASME Turbo Expo 2015: Turbine Tech. Conf. and Exposition (GT2015), Montréal, Canada, June 15–19, 2015 (ASME, New York, 2015), paper no. GT2015-42287.

R. Tschuor, G. Fruechtel, J. De Jonge, P. Meng, and Ch. Graber, “Mechanical design manufacturing of improved GT24 SEV burner,” in Proc. ASME Turbo Expo 2015: Turbine Tech. Conf. and Exposition (GT2015), Montréal, Canada, June 15–19, 2015 (ASME, New York, 2015), paper no. GT2015-43260.

G. G. Ol’khovskii, A. V. Ageev, and V. I. Kostenko, “Thermal tests of a 280 MW gas-turbine unit,” Elektr. Stn., No. 4, 288–293 (2014).

Author information

Authors and Affiliations

Corresponding author

Additional information

Original Russian Text © L.A. Bulysova, V.D. Vasil’ev, A.L. Berne, M.M. Gutnik, 2018, published in Teploenergetika.

Rights and permissions

About this article

Cite this article

Bulysova, L.A., Vasil’ev, V.D., Berne, A.L. et al. Experience Gained from Construction of Low-Emission Combustion Chambers for On-Land Large-Capacity Gas-Turbine Units: GT24/26. Therm. Eng. 65, 362–370 (2018). https://doi.org/10.1134/S0040601518060010

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S0040601518060010