Abstract

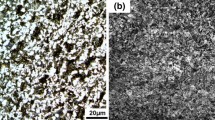

In 2014–2015, the engineers of JSC “NPO “TsNIITMash”, in cooperation with JSC “Energomash (Chekhov)—ChZEM”, developed a technology for manufacturing D u = 250 mm valve bodies from 10Kh9MFB chromium steel by electroslag melting (ESM) and produced their pilot copies within the frame of import substitution program. This article provides results of research into determining the design values of metal characteristics, including short-term mechanical properties at working temperatures and impact and long-term strength. The test specimens have been sampled from the following four zones: bottom, central, branch-pipe, and head. Tensile short-term rupture testing has been performed at temperatures of 350, 450, 500, 550, 600, and 650°С. Testing for long-term strength has been carried out at temperatures of 550, 575, 600, and 625°С and stresses of 156.8, 137.2, 117.6, and 98 MPa. To estimate brittle fracture resistance, impact-strength tests have been run at temperatures of–20 and–10°С; 20 and 50°С. The specimens have been sampled from the middle of the blank section. All short-term mechanical properties and impact strength are in agreement with the requirements imposed on the metal of hot-deformed steam piping made of 10Kh9MFB steel as per TU (Technical Conditions) 14-3R-55-2001. The absence of microliquation of alloying elements and the high homogeneity of chemical composition (as demonstrated with nine specimens) have also been experimentally confirmed. Metallographic analysis has shown that the structure of the tested metal is that of tempered martensite with local areas of tempered bainite. Overall, the microscopic structure of metal is practically the same in all the studied zones. Service-life calculation of pilot valve bodies has proved conformity with the safety-margin regulations. Such properties of electroslag melting blank as long-term strength and allowable stress correspond to the level of deformed metal and to regulations.

Similar content being viewed by others

References

V. N. Skorobogatykh, L. Ya. Levkov, I. A. Shchenkova, K. N. Utkina, P. A. Kozlov, D. A. Prudnikov, A. M. Bazhenov, D. A. Shurygin, D. K. Terekhin, and T. V. Perevezentseva, “Technology and property package of blanks of electroslag melting for TPP and NPP equipment,” Tyazh. Mashinostr., No. 11–12, 32–38 (2014).

V. N. Skorobogatykh, L. Ya. Levkov, Yu. N. Kriger, I. A. Shchenkova, A. M. Bazhenov, D. A. Prudnikov, D. A. Shurygin, N. A. Babanin, and A. A. Karev, “Production process and property package of bodyblanks of steam stop valves DN 250 from 10Kh9MFB steel,” Tyazh. Mashinostr., No. 6, 2–6 (2015).

L. Ya. Levkov, D. A. Shurygin, V. N. Skorobogatykh, I. A. Shchenkova, Yu. N. Kriger, A. M. Bazhenov, K. N. Utkina, and I. A. Ivanov, “Electroslag remelting is a promising direction in production of hollow and shaped products from steel 10X9MФБ-III,” Metallurg, No. 11, 48–53 (2016).

A. G. Glebov and E. I. Moshkevich, Electroslag Remelting (Metallurgiya, Moscow, 1985) [in Russian].

U. Duckworth and D. Hoyle, Electro-slag Refining (Chapman and Hall, London, 1969; Metallurgiya, Moscow, 1973).

M. Kubin, A. Scheriau, M. Knabl, H. Holzgruber, and H. Kawakami, “Operational experience of large sized ESR plants and attainable quality of ESR ingots with a diameter of up to 2600 mm,” in Proc. 2013 Int. Symp. on Liquid Metal Processing and Casting (LMPC), Austin, TX, Sept. 22–25, 2013 (Wiley, Hoboken, NJ, 2013), pp. 57–64.

K. A. Lanskaya, High-Chromium Heat-Resistant Steels (Metallurgiya, Moscow, 1976) [in Russian].

F. Abe, “Precipitate design for creep strengthening of 9% Cr tempered martensitic steel for ultra-supercritical power plants,” Sci. Technol. Adv. Mater. 9, 013002 (2008).

PNAE G-7-002-86. Strength Design Standards for Equipment and Pipelines of Nuclear Power Plants (Energoatomizdat, Moscow, 1989).

V. N. Skorobogatykh, I. A. Danyushevskii, I. A. Shchenkova, and D. A. Prudnikov, TU 14-3R-55-2001. Seamless Steel Pipes for Steam Boilers and Pipelines (TsNIITMASh, Moscow, 2001).

V. N. Skorobogatykh, I. A. Danyushevskiy, I. A. Schenkova, and D. A. Prudnikov, “Long-term strength and allowable stresses of grade 10Kh9MFB and X10CrMoVNb9-1 (T91/P91) chromium heat-resistant steels,” Therm. Eng. 62, 247–254 (2015). doi 10.1134/S0040601515040102

RD 10-249-98. Strength Design Standards for Stationary Boilers and Steam and Hot Water Pipelines (Promyshl. Bezop., Moscow, 2002).

Author information

Authors and Affiliations

Corresponding author

Additional information

Original Russian Text © V.N. Skorobogatykh, I.A. Schenkova, I.A. Danyushevskiy, E.A. Grin’, L.Ya. Levkov, D.A. Prudnikov, D.N. Zhuravlev, A.M. Bazhenov, 2017, published in Teploenergetika.

Rights and permissions

About this article

Cite this article

Skorobogatykh, V.N., Schenkova, I.A., Danyushevskiy, I.A. et al. Application experience of grade 10Kh9MFB chromium steel for steam shutoff and control valve bodies. Therm. Eng. 64, 272–279 (2017). https://doi.org/10.1134/S0040601517040085

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S0040601517040085