Abstract

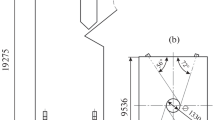

Development of a coal-fired boiler for a power plant unit of 800 MW with advanced ultra-supercritical steam parameters of 35 MPa and 700/720°C is presented. The main technical solutions providing the reliability, profitability, and low emissions of harmful substances in the atmosphere are given. The fuel is the black coal of (Taldinskoye field, Kuznetsk basin). The gross efficiency of the boiler is 94%. The U-shaped configuration of a boiler is chosen, which allows the reduction of the capital expenditure for steam turbine piping made of expensive nickel alloys. The horizontal connection flue of the boiler, where the primary and reheat steam screens are located, is equipped with two cold funnels. The upper section of the convection shaft is separated with a vertical screen wall into two parallel “split tail” flues, which allows one to control the reheat steam temperature by redistributing the flue gas between the gas flues. The URS screens are two-stage with a lifting motion of the medium and a partial bypassing of the first stage. The lower radiant section is two-stage. To reduce the temperature of screen walls at the fire chamber outlet, the lowering motion of the working medium and combustion gases is used. The hydrodynamics of the screens with the lowering motion of the medium for preventing the aperiodic instability in the start regimes is analyzed. Besides the stepwise combustion of coal dust providing the improved environmental parameters, the boiler plant is equipped with a selective catalytic reduction (SCR) system, an ash collector (an electric filter combined with a filter bag), and a desulphurization device.

Similar content being viewed by others

References

D. Hourfar, “Clean coal technologies–A brief survey 700°C technology. IGCC, Carbon Capture,” in Proc. Int. Conf. on Efficient and Clean Coal Technologies, Moscow, 2009.

E. V. Somova, A. L. Shvarts, and E. Kh. Verbovetsky, “Project a coal-fired power Advanced ultra-super critical on steam parameters within the framework of the European project AD-700,” Energetik, No. 2, 39–42 (2015).

G. Tumanovskii, A. L. Shvarts, G. D. Avrutsky, B. E. Shkolnikova, V. I. Gladshtein, A. A. Chugreev, and M. V. Lazarev, “The results of generalization of mastering the first national unit at supercritical steam parameters for use in the development of the coal power industry of Russia,” Elektr. Stantsii, No. 6, 4–12 (2012).

Author information

Authors and Affiliations

Corresponding author

Additional information

Original Russian Text © A.L. Shvarts, E.Kh. Verbovetsky, E.V. Somova, A.V. Smolin, 2015, published in Teploenergetika.

Rights and permissions

About this article

Cite this article

Shvarts, A.L., Verbovetsky, E.K., Somova, E.V. et al. Development of technical solutions on a coal-fired boiler for a power plant unit of 800 MW with steam parameters of 35 MPa and 700/720°C. Therm. Eng. 62, 892–896 (2015). https://doi.org/10.1134/S0040601515120083

Published:

Issue Date:

DOI: https://doi.org/10.1134/S0040601515120083