Abstract

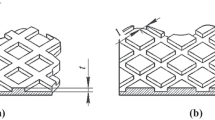

The work studies methods to improve the wettability of polymer packing elements involving the application of various geometric structures onto their surface. The authors of this work review the latest scientific studies that consider the phenomena of wetting on structured surfaces. A laboratory bench is developed for the study the profile and character of the flow of a liquid film over polymer plates with different surface structures. It is noted based on the results of the performed studies that the wettability of the surface strongly depends on its structure. A qualitative and quantitative comparison of the degree of wettability of the studied plates is presented, during which it is found that a network configuration of the surface of the plate is the most efficient. Recommendations on the practical application of the results of this work are indicated based on the obtained data.

Similar content being viewed by others

REFERENCES

Mareshova, L.A., Bogatykh, K.F., Rol’nik, L.Z., and Yagafarova, G.G., Results of the industrial implementation of developments of regular cross-flow packings by scientists of the Ufa State Petroleum Technological University, Neftegazov. Delo, 2007, no. 1, p. 74.

Farakhov, M.I. and Lapteva, E.A., Energy saving in an ethanolamine separation plant, Izv. Vyssh. Uchebn. Zaved., Probl. Energ., 2008, nos. 7–8, p. 133.

Leont’ev, V.S., Innovations in the development of high-intensity mass-transfer equipment for modernization of distillation plants, Neftegazov. Delo, 2012, no. 1, p. 178.

Farakhov, M.I., Laptev, A.G., and Basharov, M.M., Modernization of mass-exchange equipment by new packings in chemical engineering, Theor. Found. Chem. Eng., 2015, vol. 49, no. 3, p. 233.

Kagan, A.M., Yudina, L.A., and Pushnov, A.S., Active surface of the elements of irregular heat and mass transfer packings, Theor. Found. Chem. Eng., 2012, vol. 46, no. 2, p. 165.

Contact Packings of Industrial Heat- and Mass-Transfer Equipment, Laptev, A.G., Ed., Kazan: Otechestvo, 2013.

Ivanov, S.P., Polymer Cooling Tower Fillers, Moscow: Inter, 2009.

Laptev, A.G. and Ved’gaeva, I.A., Design and Calculation of Industrial Cooling Towers, Kazan: Kazan. Gos. Energ. Univ., 2004.

Golovanov, I.Yu., Efficiency of the replacement of ceramic and metallic elements of packings by polymer elements by the example of a regular packing of Raschig rings, in Role of Innovation in Transformation of Modern Science: Proceedings of International Scientific and Practical Conference, Magnitogorsk, 2019, p. 80.

Knyazev, S.D., Promising methods to improve the wettability of the surface of packings made of polymer materials, in Scientific Outlooks 2020: Proceedings of Regional Youth Science and Technology Conference, Dzerzhinsk, 2020, p. 56.

Doroshenko, A.V. and Vasyutinskii, S.Yu., Improvement of heat- and mass-transfer equipment for energy systems, Probl. Reg. Energ., 2008, no. 2, p. 32.

Yoshiyuki, I. and Xi, C., Development of numerical prediction of liquid film flows on packing elements in absorbers, Eng. Rev., 2011, vol. 11, no. 2, p. 1.

Cooke, J.J., Gu, S., Armstrong, L.M., and Luo, K.H., Gas–liquid flow on smooth and textured inclined planes, Int. Scholarly Sci. Res. Innovation, 2012, vol. 6, no. 8, p. 1446.

Pavlenko, A.N., Volodin, O.A., and Serdyukov, V.S., Specific features of the film flow of liquid nitrogen over structured surfaces, Vestn. Novosib. Gos. Univ., Ser.: Fiz., 2015, vol. 10, no. 1, p. 33.

Pushnov, A.S., Gorodilov, A.A., and Berengarten, M.G., Hydrodynamics of liquid jet spreading on the corrugated surface of a regular packing with perforated elements, Khim. Tekhnol., 2014, vol. 15, no. 6, p. 364.

Gorodilov, A.A., Berengarten, M.G., and Pushnov, A.S., Features of fluid film falling on the corrugated surface of structured packings with perforations, Theor. Found. Chem. Eng., 2016, vol. 50, no. 3, p. 325.

Gorodilov, A.A., Pushnov, A.S., and Berengarten, M.G., Spreading of a fluid jet on the corrugated surface of the structured packing of wet scrubbers, Probl. Reg. Energ., 2014, no. 2, p. 57.

Nakae, H., Yoshida, M., and Yokota, M., Effects of roughness pitch of surfaces on their wettability, J. Mater. Sci., 2005, vol. 40, p. 2287.

Junchao, W., Yankun, M., Yijun, C., Guosheng, L., and Yinfei, L., Influence of surface roughness on contact angle hysteresis and spreading, Colloid Polym. Sci., 2020, vol. 298, p. 1107.

Kubiak, K.J., Wilson, M.C.T., Mathia, T.G., and Carval, Ph., Wettability versus roughness of engineering surfaces, Wear, 2011, vol. 271, nos. 3–4, p. 523.

Sharipov, I.I., Kruglov, L.V., Kruglov, V.I., and Dmitrieva, O.S., Design of a jet–film contact apparatus to intensify the heat and mass transfer, Izv. Vyssh. Uchebn. Zaved., Probl. Energ., 2018, vol. 20, nos. 9–10, p. 146.

Naz, M.Ya., Suleiman, Sh.A., Erivadzhudi, B., and Kuzilati, K., Visualization of the hot water aerosol jet breakup initiated by conical-flame burners, Prikl. Mekh. Tekh. Fiz., 2015, vol. 56, no. 2, p. 53.

Aktershev, S.P. and Alekseenko, S.V., Wavy flow of an evaporating liquid film, Izv. Tomsk. Politekh. Univ., 2014, vol. 324, no. 4, p. 6.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

The authors declare that they have no conflicts of interest.

Additional information

Translated by E. Boltukhina

Rights and permissions

About this article

Cite this article

Vasiliev, P.D., Sidyagin, A.A., Stepykin, A.V. et al. Influence of the Surface Structure on the Wettability of Polymer Packing Elements in Heat- and Mass-Transfer Equipment. Theor Found Chem Eng 56, 212–220 (2022). https://doi.org/10.1134/S0040579522020166

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S0040579522020166