Abstract

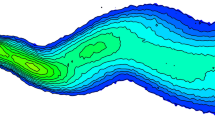

The planar laser induced fluorescence (PLIF) technique is applied to investigate the flow and liquid mixing characteristics in submerged top-blow process. The liquid mixing effects are analyzed in terms of plane mixing uniformity U(t) and mixing time t95 at different air flow rate and lance submergence depth. Based on experimental data, the liquid mixing process has been divided into three stages by mixing uniformity U, the beginning stage (0.9 < U < 1) , the interim stage (0.1 < U < 0.9) and the end stage (0 < U < 0.1), the value of U drops slowly in the beginning stage and the end stage, but drops rapidly in the interim stage. The mixing time t95 is decreased obviously when increasing the air flow rate and lance submergence depth. There are significant local mixing differences in the liquid mixing process when the lance submergence depth is small. The local difference decreases evidently as the air flow rate and the lance submergence depth increase. The local differences are gradually eliminated when the lance approaches the container bottom.

Similar content being viewed by others

REFERENCES

El-Katatny, I., Morsi, Y.S., and Yang, W., Numerical characterisation and experimental validation of AusIron top submerged multi-injection system, Ironmaking Steelmaking, 2008, vol. 35, no. 2, pp. 91–98.

Hoang, J., Reuter, M.A., Matusewicz, R., Hughes, S., and Piret, N., Top submerged lance direct zinc smelting, Miner. Eng., 2009, vol. 22, nos. 9–10, pp. 742–751.

Qi, C., Wang, W., Wang, B., Kuang, Y., and Xu, J., Performance analysis of submerged combustion vaporizer, J. Nat. Gas Sci. Eng., 2016, vol. 31, pp. 313–319.

Huda, N., Naser, J., Brooks, G., Reuter, M.A., and Matusewicz, R.W., A computational fluid dynamic modeling study of slag fuming in top submerged lance smelting furnace, Proc. World Congress on Engineering 2010 (WCE 2010) (London, 2010), Hong Kong: International Association of Engineers, 2010, vol. 2, pp. 1069–1074.

Huda, N., Naser, J., Brooks, G., Reuter, M.A., and Matusewicz, R.W., Computational fluid dynamic modeling of zinc slag fuming process in top-submerged lance smelting furnace, Metall. Mater. Trans. B, 2012, vol. 43, no. 1, pp. 39–55.

Llanos, C.A., Garcia, S., Ramos-Banderas, J.A., Barreto, J.D.J., and Solorio, G., Multiphase modeling of the fluidynamics of bottom argon bubbling during ladle operations, ISIJ Int., 2010, vol. 50, no. 3, pp. 396–402. https://doi.org/10.2355/isijinternational.50.396

Morsi, Y.S., Yang, W., Achim, D., and Acquadro, A., Numerical and experimental investigation of top submerged gas injection system, WIT Trans. Modell. Simul., 2001, vol. 50, pp. 95–104.

Morsi, Y.S., Yang, W., and El-Katatny, I., Experimental characterisation of AusIron top submerged injection system, Ironmaking Steelmaking, 2008, vol. 35, no. 1, pp. 69–74.

Cho, S.M., Kim, S.H., and Thomas, B.G., Transient fluid flow during steady continuous casting of steel slabs: Part I. Measurements and modeling of two-phase flow, ISIJ Int., 2014, vol. 54, no. 4, pp. 845–854.

Wang, S.B., Wang, H., Xu, J.X., Zhu, D.F., Sun, H., and Li, H.J., Hot-state numerical simulation study on top-blown bath in ISA furnace, Adv. Mater. Res., 2012, vol. 383, pp. 7406–7412.

Kochi, N., Mori, K., Sasaki, Y., and Iguchi, M., Mixing time in a cylindrical bath agitated by gas injection through an L-shaped top lance in the absence of swirl motion, ISIJ Int., 2011, vol. 51, no. 11, pp. 1755–1761.

Kochi, N., Mori, K., Sasaki, Y., and Iguchi, M., Mixing time in a bath in the presence of swirl motion induced by horizontal gas injection with an L-shaped lance, ISIJ Int., 2011, vol. 51, no. 3, pp. 344–349.

Morsi, Y.S., Yang, W., Clayton, B.R., and Gray, N.B., Experimental investigation of swirl and non-swirl gas injections into liquid baths using submerged vertical lances, Can. Metall. Q., 2000, vol. 39, no. 1, pp. 87–98.

Nordquist, A., Kumbhat, N., Jonsson, L., and Jönsson, P., The effect of nozzle diameter, lance height and flow rate on penetration depth in a top-blown water model, Steel Res. Int., 2006, vol. 77, no. 2, pp. 82–90.

Ramírez-Argáez, M.A., Numerical simulation of fluid flow and mixing in gas-stirred ladles, Adv. Manuf. Processes, 2007, vol. 23, no. 1, pp. 59–68.

Tago, Y. and Higuchi, Y., Fluid flow analysis of jets from nozzles in top blown process, ISIJ Int., 2003, vol. 43, no. 2, pp. 209–215.

Zhao, H., Zhang, L., Yin, P., and Wang, S., Bubble motion and gas-liquid mixing in metallurgical reactor with a top submerged lance, Int. J. Chem. React. Eng., 2017, vol. 15, no. 3. https://doi.org/10.1515/ijcre-2016-0139

Hu, Y., Liu, Z., Yang, J., Jin, Y., and Cheng, Y., Study on the reactive mixing process in an unbaffled stirred tank using planar laser-induced fluorescence (PLIF) technique, Chem. Eng. Sci., 2010, vol. 65, no. 15, pp. 4511–4518.

Hu, Y., Wang, W., Shao, T., Yang, J., and Cheng, Y., Visualization of reactive and non-reactive mixing processes in a stirred tank using planar laser induced fluorescence (PLIF) technique, Chem. Eng. Res. Des., 2012, vol. 90, no. 4, pp. 524–533.

Stamatopoulos, K., Alberini, F., Batchelor, H., and Simmons M.J., Use of PLIF to assess the mixing performance of small volume USP 2 apparatus in shear thinning media, Chem. Eng. Sci., 2016, vol. 145, pp. 1–9.

Xia, Q. and Zhong, S., A PLIF and PIV study of liquid mixing enhanced by a lateral synthetic jet pair, Int. J. Heat Fluid Flow, 2012, vol. 37, pp. 64–73.

Xia, Q. and Zhong, S., Liquid mixing enhanced by pulse width modulation in a Y-shaped jet configuration, Fluid Dyn. Res., 2013, vol. 45, no. 2, p. 025504.

Zhang, M., Hu, Y., Wang, W., Shao, T., and Cheng, Y., Intensification of viscous fluid mixing in eccentric stirred tank systems, Chem. Eng. Process., 2013, vol. 66, pp. 36–43.

ACKNOWLEDGMENTS

We graciously acknowledge Dr. Xiaohui Zhang in Kunming University of Science and Technology for his warmly help in the experiments.

Funding

Our work has been financially supported by the Natural Science Foundation of China (nos. 51666006, U1602272) and Yunnan Natural Science Foundation Youth Fund Project (no. 2017FD080).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Rong Chen, Zhang, S., Ai, Y. et al. Liquid Mixing Characteristics in Top-Blown Process. Theor Found Chem Eng 55, 417–425 (2021). https://doi.org/10.1134/S0040579521030039

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S0040579521030039