Abstract

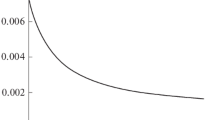

The problem of describing heat and mass transfer upon drying the spherical particle in oscillating electromagnetic field under boundary conditions of heat and mass transfer of the third kind has been formulated and analytically solved. The numerical analysis of the process has been performed.

Similar content being viewed by others

References

Ginzburg, A.S., Application of Infrared Radiation in Food Processing, London: Leonard Hill, 1969.

Ratti, C. and Mujumdar, A.S., Infrared drying, in Handbook of Industrial Drying, Mujumdar, A.S., Ed., Boca Raton, Fla.: CRC, 2007, p. 423.

Akulich, P.V., Dragun, V.L., and Kuts, P.S., Tekhnologii i tekhnika sushki i termoobrabotki materialov (Drying and Thermal Treatment Technologies and Techniques), Minsk: Belorusskaya Nauka, 2006.

Kudra, T. and Strumillo, Cz., Thermal Processing of Biomaterials, Amsterdam: Gordon and Breach, 1998.

Bon, J. and Kudra, T., Enthalpy-driven optimization of intermittent drying, Drying Technol., 2007, vol. 25, no. 4, p. 523.

Vaquiro, H.A., Clemente, G., García-Pérez, J.V., Mulet, A., and Bonb, J., Enthalpy-driven optimization of intermittent drying of Mangifera indica L, Chem. Eng. Res. Des, 2009, vol. 87, p. 885.

Rudobashta, S.P. and Grigor’ev, I.V., Pulse infrared drying of seeds, Prom. Teplotekh., 2011, vol. 33, no. 8, p. 85.

Kian Jon Chua and Siaw Kiang Chou., A comparative study between intermittent microwave and infrared drying of bioproducts, Int. J. Food Sci. Technol., 2005, vol. 40, no. 1, p. 23.

Afanas’ev, A.M. and Siplivyi, B.N., Dependence of quality of microwave drying on the depth of electromagnetic wave penetration, Fiz. Voln. Prots. Radiotekh. Sist., 2008, vol. 11, no. 1, p. 95.

Afanas’ev, A.M., Mikhailov, V.K., and Siplivyi, B.N., Mathematical modeling of two-dimensional problems of the theory of electromagnetic drying, Biomed. Radioelektron., 2008, no. 11, p. 29.

Perre, P. and Turner, I.A., A complete coupled model of the combined microwave and convective drying of softwood in an oversized waveguide, Proc. 10th Int. Drying Symp. (IDS’96), Krakow, Poland, 1996, p. 183.

Grinchik, N.N., Akulich, P.V., Adamovich, A.L., Kuts, P.S., and Kundas, S.P., Modeling of nonisothermal heat and moisture transfer in capillary-porous media in periodic microwave heating, J. Eng. Phys. Thermophys., 2007, vol. 80, no. 1, p. 1.

Akulich, P.V., Temruk, A.V., and Akulich, A.V., Modeling and experimental investigation of the heat and moisture transfer in the process of microwave-convective drying of vegetable materials, J. Eng. Phys. Thermophys., 2012, vol. 85, no. 5, p. 1034.

Likitrattanaporn, Ch. and Noomhorm, Ath., Effects of simultaneous parboiling and drying by infrared radiation heating on parboiled rice quality, Drying Technol., 2011, vol. 29, no. 9, p. 1066.

Rudobashta, S.P., Kartashov, E.M., and Zuev, N.A., Heat and mass transfer in drying in oscillating electromagnetic field, Theor. Found. Chem. Eng., 2011, vol. 45, no. 6, p. 830.

Zuev, N.A., Drying and pre-sowing stimulation of seeds with an oscillating electromagnetic field in the infrared frequency range, Cand. Sci. (Eng.) Dissertation, Moscow: Moscow State Univ. of Agricultural Engineering, 2013.

Rudobashta, S.P., Zueva, G.A., and Zuev, N.A., Seed stimulation by oscillating infrared thermal treatment, Prom. Teplotekh., 2013, vol. 35, no. 7, p. 218.

Kowalski, S.J. and Rajewska, K., Convective drying enhanced with microwave and infrared radiation, Drying Technol., 2009, vol. 27, nos. 7–8, p. 878.

Puente-Díaz, L. Kong Ah-Hen., Vega-Gálvez, A., Lemus-Mondaca, R., and Di Scala, K., Combined infrared–convective drying of murta (Ugni molinae turcz) berries: Kinetic modeling and quality assessment, Drying Technol., 2013, vol. 31, no. 3, p. 329.

Frolov, V.F., Modelirovanie sushki dispersnykh materialov (Simulation of Dispersed Material Drying), Leningrad: Khimiya, 1987.

Fedosov, S.V., Teplomassopernos v tekhnologicheskikh protsessakh stroitel’noi industrii (Heat and Mass transfer in Processes of the Building Industry), Ivanovo: IPK “PresSto,” 2010.

Rudobashta, S.P., Mathematical simulation of the convective drying of dispersed materials, Izv. Ross. Akad. Nauk. Energ., 2000, no. 4, p. 98.

Padokhin V.A., Zueva G.A., Kokurina G.N., Kochkina N.E., and Fedosov, S.V., Complex mathematical description of heat and mass transfer in the drying of an infinite cylindrical body with analytical methods of heat-conduction theory, Theor. Found. Chem. Eng., 2015, vol. 49, no. 1, p. 50.

Lykov, A.V., Teoriya sushki (Theory of Drying), Moscow: Energiya, 1968.

Rudobashta, S.P., Massoperenos v sistemakh s tverdoi fazoi (Mass Transfer in Systems with a Solid Phase), Moscow: Khimiya, 1980.

Rudobashta, S.P. and Kartashov, E.M., Diffuziya v khimiko-tekhnologicheskikh protsessakh (Diffusion in Chemical Technology Processes), Moscow: KolosS, 2010.

Kartashov, E.M., Analiticheskie metody v teorii teploprovodnosti tverdykh tel (Analytical Methods in the Thermal Conduction Theory of Solids), Moscow: Vysshaya Shkola, 2001.

Lykov, A.V., Teoriya teploprovodnosti (Thermal Conduction Theory), Moscow: Vysshaya Shkola, 1967.

Rudobashta, S.P., Zueva, G.A., and Zuev, N.A., Mass conductivity in the drying of colloid capillary-porous materials, Izv. Vyssh. Uchebn. Zaved., Ser.: Khim. Khim. Tekhnol., 2014, vol. 57, no. 1, p. 103.

Rudobashta, S.P., Zueva, G.A., and Zuev, N.A., Hygroscopic properties of seeds, Izv. Vyssh. Uchebn. Zaved., Ser.: Khim. Khim. Tekhnol., 2015, vol. 58, no. 1, p. 68.

Teplofizicheskie kharakteristiki pishchevykh produkto:. Spravochnoe posobie (Thermophysical Characteristics of Food Products: A Handbook), Ginzburg, A.S., Ed., Moscow: Pishchevaya Prom–st., 1975.

Teoreticheskie osnovy teplotekhniki. Teplotekhnicheskii eksperiment: Spravochnik (Theoretical Foundations of Thermal Engineering. Thermotechnical Experiment: A Handbook), Grigor’ev, V.A. and Zorin, V.M., Eds., Moscow: Energoatomizdat, 1988, Vol. 2.

Aksel’rud, G.A. and Lysyanskii, V.M., Ekstragirovanie: Sistema tverdoe telo-zhidkost’ (Extracton: Solid–Liquid Systems), Leningrad: Khimiya, 1974.

Planovskii, A.N., Mushtaev, V.I., and Ul’yanov, V.M., Sushki ofdispersnykh materialov v khimicheskoi promyshlennosti (Drying of Dispersed Materials in the Chemical Industry), Moscow: Khimiya, 1979.

Aerov, M.E. and Todes, O.M., Gidravlicheskie i teplovye osnovy raboty apparatov so statsionarnym i kipyashchim zernistym sloem (Hydraulic and Thermal Principles of the Operation of Fixed-and Fluidized-Bed Apparatuses), Moscow: Khimiya, 1968.

Author information

Authors and Affiliations

Corresponding author

Additional information

Original Russian Text © S.P. Rudobashta, G.A. Zueva, E.M. Kartashov, 2016, published in Teoreticheskie Osnovy Khimicheskoi Tekhnologii, 2016, Vol. 50, No. 5, pp. 539–550.

Rights and permissions

About this article

Cite this article

Rudobashta, S.P., Zueva, G.A. & Kartashov, E.M. Heat and mass transfer when drying a spherical particle in an oscillating electromagnetic field. Theor Found Chem Eng 50, 718–729 (2016). https://doi.org/10.1134/S0040579516050365

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S0040579516050365