Abstract

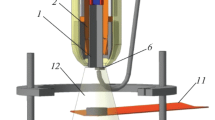

Using the Cr3C2–NiAl cathode prepared by self-propagating high-temperature synthesis, Cr‒Ni–Al–C–N coatings are deposited by pulsed cathode arc evaporation in argon, nitrogen, and ethylene atmospheres. The coating structures are investigated by scanning electron microscopy, X-ray diffraction analysis, glow-discharge optical emission spectroscopy, and Raman spectroscopy. Mechanical and tribological properties are investigated by nanoindentation and pin-on-disk tribological testing. Anticorrosion properties are evaluated by voltammetry in the medium of a 1-N H2SO4 solution. The nonreactive coating deposited in an inert Ar atmosphere contains the Cr3C2 fcc phase with a size of crystallites below 20 nm. The deposition in the C2H4 and N2 reaction media leads to amorphization of the coatings. The samples deposited in argon and nitrogen exhibit high hardness values of 24–25 GPa. The deposition of coatings in C2H4 gives rise to a 40% decrease in the hardness. However, the carbon-containing sample has a relatively low coefficient of friction at a level of 0.28, as well as better wear and corrosion resistances due to the positive effect of the diamond-like carbon phase.

Similar content being viewed by others

REFERENCES

Ph. V. Kiryukhantsev-Korneev, A. N. Sheveyko, S. A. Vorotilo, and E. A. Levashov, “Wear-resistant Ti–Al–Ni–C–N coatings produced by magnetron sputtering of SHS-targets in the DC and HIPIMS modes,” Ceram. Int. 46, 1775–1783 (2019).

Ph. Kiryukhantsev-Korneev, A. Sytchenko, A. Sheveyko, D. Moskovskikh, and S. Vorotylo, “Two-layer nanocomposite TiC-based coatings produced by a combination of pulsed cathodic arc evaporation and vacuum electro-spark alloying,” Materials 13, No. 547 (2020).

X. Zhao, Z. Chen, H. Wang, Z. Zhang, G. Shao, R. Zhang, B. Fan, H. Lu, H. Xu, and D. Chen, “The influence of additive and temperature on thermal shock resistance of ZrB2 based composites fabricated by Spark Plasma Sintering,” Mater. Chem. Phys. 240, No. 122061 (2020).

M. Antonov and I. Hussainova, “Thermophysical properties and thermal shock resistance of chromium carbide based cermets,” Proc. Estonian Acad. Sci. Eng. 12, 358–367 (2006).

E. Almandoz, De Ara J. Fernandez, J. De Bujanda Martinez, J. Palacio Fernandez, R. Jose Rodriguez, Z. Zhang, H. Dong, Y. Qin, and G. Garcia Fuentes, “CrAlON CAE-PVD coatings for oxidation and wear protection of TZM alloys in FAST sintering applications,” Mater. Chem. Phys. 208, 189–197 (2018).

V. S. Goncharov, E. V. Vasil’ev, and M. V. Goncharov, “Effect of technological parameters of applying yttrium-containing coatings on their structure and properties,” Phys. Metals. Metallogr. 115, 169–174 (2014).

R. Krause-Rehberg, A. D. Pogrebnyak, V. N. Borisyuk, M. V. Kaverin, A. G. Ponomarev, M. A. Bilokur, K. Oyoshi, Y. Takeda, V. M. Beresnev, and O.V. Sobol’, “Analysis of local regions near interfaces in nanostructured multicomponent (Ti–Zr–Hf–V–Nb)N coatings produced by the cathodic-arc-vapor-deposition from an arc of an evaporating cathode,” Phys. Met. Metallogr. 114, 672–680 (2013).

Ph. V. Kiryukhantsev-Korneev and K. A. Kuptsov, “Impact wear-resistance of Ti–Cr–B–N coatings produced by pulsed CAE of ceramic target,” J. Phys.: Conf. Ser. 1238, No. 012003 (2019).

H. Shafyei, M. Salehi, and A. Bahrami, “Fabrication, microstructural characterization and mechanical properties evaluation of Ti/TiB/TiB2 composite coatings deposited on Ti6Al4V alloy by electro-spark deposition method,” Ceram. Int. 46, 15276–15284 (2020).

P. E. Hovsepian and A. P. Ehiasarian, “Six strategies to produce application tailored nanoscale multilayer structured PVD coatings by conventional and High Power Impulse Magnetron Sputtering (HIPIMS),” Thin Solid Films 688, No. 137409 (2019).

MH. Mei, J. C. Ding, X. Xiao, Q. Luo, R. Wang, Q. Zhang, W. Gong, and Q. Wang, “Influence of pulse frequency on microstructure and mechanical properties of Al–Ti–V–Cu–N coatings deposited by HIPIMS,” Surf. Coat. Technol. 405, No. 126514 (2021).

F. Ferreira, R. Serra, J. C. Oliveira, and A. Cavaleiro, “Effect of peak target power on the properties of Cr thin films sputtered by HiPIMS in deep oscillation magnetron sputtering (DOMS) mode,” Surf. Coat. Technol. 258, 249–256 (2014).

J. F. Kiryukhantsev-Korneev and K. A. Pierson, “Hard Cr–Al–Si–B–(N) coatings deposited by reactive and non-reactive magnetron sputtering of CrAlSiB target,” Appl. Surf. Sci. 314, 104–111 (2014).

SD. V. Shtansky, N. A. Gloushankova, A. N. Sheveiko, P. V. Kiryukhantsev-Korneev, I. A. Bashkova, B. N. Mavrin, S. G. Ignatov, S. Y. Filippovich, and C. Rojas, “Si-doped multifunctional bioactive nanostructured films,” Surf. Coat. Technol. 205, 728–739 (2010).

M. Shi, Z. Xue, H. Liang, Z. Yan, X. Liu, and S. Zhang, “High velocity oxygen fuel sprayed Cr3C2–NiCr coatings against Na2SO4 hot corrosion at different temperatures,” Ceram. Int. 46, 23629–23635 (2020).

Y. Zhang, K. Chong, Q. Liu, Y. Bai, Z. Zhang, D. Wu, and Y. Zou, “High-temperature tribological behavior of thermally-treated supersonic plasma sprayed Cr3C2-NiCr coatings,” Int. J. Refract. Met. Hard Mater. 95, No. 105456 (2021).

H. Lu, J. Shang, X. Jia, Y. Li, F. Li, J. Li, and Y. Nie, “Erosion and corrosion behavior of shrouded plasma sprayed Cr3C2–NiCr coating,” Surf. Coat. Technol. 388, No. 125534 (2020).

V. Suresh, A. Jegan, and S. L. Kumar, “Microstructure, mechanical and tribological characteristics of plasma and HVOF sprayed Cr3C2–PS.ZrO2 coatings,” Mater. Today: Proc. 33, 1137–1143 (2020).

S. Kumar, D. Mudgal, S. Singh, and S. Prakash, “Effect of CeO2 in Cr3C2–NiCr Coating on Superni 600 at High Temperature,” Procedia Mater. Sci. 6, 939–949 (2014).

W. Zhai, B. Pu, L. Sun, Y. Wang, H. Dong, Q. Gao, L. He, and Y. Gao, “Influence of molybdenum content and load on the tribological behaviors of in-situ Cr3C2–20 wt % Ni composites,” J. Alloys Compd. 826, 154180 (2020).

J.-Y. Du, Y.-L. Li, F.-Y. Li, X.-J. Ran, X.-Y. Zhang, and X.-X. Qi, “Research on the high temperature oxidation mechanism of Cr3C2–NiCrCoMo coating for surface remanufacturing,” J. Mater. Res. Technol. 10, 565–579 (2021).

Ph. V. Kiryukhantsev-Korneev, A. D. Sytchenko, V. A. Gorshkov, and E. A. Levashov, “Mass-transfer kinetics, structure, and tribological properties of coatings deposited on steel in Ar or N2 + O2 by electro-spark alloying using Cr3C2–NiAl electrodes,” IOP Conf. Ser.: Mater. Sci. Eng. 848, No. 012087 (2020).

Ph. V. Kiryukhantsev-Korneev, N. V. Shvyndina, A. D. Sytchenko, D. V. Shtansky, V. A. Gorshkov, and E. A. Levashov, “Healing effect in coatings deposited by hybrid technology of vacuum electro-spark alloying, pulsed cathodic arc evaporation, and magnetron sputtering using Cr3C2–NiAl electrodes,” J. Phys.: Conf. Ser. 1431, No. 012027 (2020).

F.V. Kiryukhantsev-Korneev, “Possibilities of glow discharge optical emission spectroscopy in the investigation of coatings,” Rus. J. Non-Ferrous Met. 55, 494–504 (2014).

P. J. Martin and A. Bendavid, “Review of the filtered vacuum arc process and materials deposition,” Thin Solid Films 394, 1–14 (2001).

J. Laumer, K. Schmidt, and S. K. O’Leary, “The relationship between the Raman spectral form and the location of the corresponding sample within the overall thin-film carbon genome,” Solid State Commun. 322, No. 114059 (2020).

B. Warcholinski, A. Gilewicz, P. Myslinski, E. Dobruchowska, D. Murzynski, P. Kochmanski, K. Rokosz, and S. Raaen, “Effect of nitrogen pressure and substrate bias voltage on the properties of Al–Cr–B–N coatings deposited using cathodic arc evaporation,” Tribol. Int. 154, No. 106744 (2021).

F. V. Kiryukhantsev-Korneev and A. V. Bondarev, “Structure and properties of antifriction Cu, Cu–C, and DLC coatings,” Phys. Met. Metallogr. 120, 702–708 (2019).

M. M. Khrushchev, E. A. Marchenko, I. S. Levin, V. M. Avdyukhina, M. D. Reilyanu, E. A. Obraztsova, and M. V. Atamanov, “Structure and tribological behavior of chromium-carbon coatings obtained by magnetron sputtering,” Phys. Met. Metallogr. 120, 204–209 (2019).

J. Musil, F. Kunc, H. Zeman, and H. Polakova, “Relationships between hardness, Young’s modulus and elastic recovery in hard nanocomposite coatings,” Surf. Coat. Technol. 154, 304–313 (2002).

Z. Guo, A. Zhang, J. Han, and J. Meng, “Microstructure, mechanical and tribological properties of CoCrFeNiMn high entropy alloy matrix composites with addition of Cr3C2,” Tribol. Int. 151, No. 106436 (2020).

M. H. Staia, T. Valente, C. Bartuli, D. B. Lewis, C. P. Constable, A. Roman, J. Lesage, D. Chicot, and G. Mesmacque, “Part II: tribological performance of Cr3C2–25% NiCr reactive plasma sprayed coatings deposited at different pressures,” Surf. Coat. Technol. 146–147, 563–570 (2001).

Funding

In part of electrochemical studies, this work was supported by the Russian Science Foundation (contract no. 20-79-10104).

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated by O. Kadkin

Rights and permissions

About this article

Cite this article

Kiryukhantsev-Korneev, P.V., Sytchenko, A.D., Sheveyko, A.N. et al. Effect of a Gas Medium on the Mechanical, Tribological, and Anticorrosion Properties of Cr–Ni–Al–C–N Coatings Deposited by the Pulsed Cathodic Arc Evaporation Method. Phys. Metals Metallogr. 122, 1241–1247 (2021). https://doi.org/10.1134/S0031918X21120048

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S0031918X21120048