Abstract—

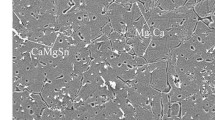

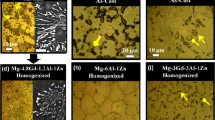

The effect of annealing conditions of the cold-rolled strip made of a new aluminum–magnesium alloy 1565ch, containing zinc and zirconium, on the evolution of the grain structure has been analyzed in this work. This material was recently developed by Russian scientists and has already been used in transport engineering, but has not yet been sufficiently studied. Recrystallization processes occurring in this alloy and their connection with intermetallic particles are of particular interest. This work is aimed at studying the effect of the temperature and annealing time on the grain size in the 1565ch alloy. The grain structure has been studied by optical microscopy, and the intermetallic particles have been studied by scanning electron microscopy. In addition, the phase composition of the 1565ch alloy has been calculated using Thermo-Calc software. The grain size after achieving the recrystallization threshold has been shown to be insensitive to the annealing time and directly depends only on the annealing temperature, which no longer has a noticeable effect after 350°C. The 1565ch alloy tends to recrystallization with involving coarse intermetallic particles of the second phase. These particles are Al6(Mn, Fe) and Mg2Si. In addition, the effect of fine intermetallic particles on the recrystallization process has been investigated. The dissolution and coagulation of the fine particles in this alloy provoke rapid recrystallization.

Similar content being viewed by others

REFERENCES

N. A. Belov, O. O. Stolyarova, T. I. Murav’eva, and D. L. Zagorskii. “Phase composition and structure of aluminum Al–Cu–Si–Sn–Pb alloys,” Phys. Met. Metallogr. 117, 579–587 (2016).

V. V. Zakharov, “About alloying of aluminum alloys with transition metals,” Metal. Sci. Heat Treat. 59, 67–71 (2017).

A. S. Oryshchenko, E. P. Osokin, N. N. Barakhtina, and A. M. Drits, “Aluminum-magnesium alloy 1565ch for cryogenic application,” Tsvetn. Met., No. 11, 84–90 (2012).

G. E. Totten and D. S. MacKenzie, Handbook of Aluminum: Vol. 1: Physical Metallurgy and Processes (Marcel Dekker, New York, 2003).

B. A. Kolachev, V. A. Livanov, and V. I. Elagin, Metal Science and Heat Treatment of Metals and Alloys (Metallurgiya, Moscow, 1981) [in Russian].

J. Murray, A. Peruzzi, and J. P. Abriata, “The Al–Zr (aluminum–zirconium) system,” J. Phase Equilib. 13, 277–291 (1992).

F. Wang, Z. Liu, D. Qiu, J. A. Taylor, M. A. Easton, and M. X. Zhang, “Revisiting the role of peritectics in grain refinement of Al alloys,” Acta Mater. 61, 360–370 (2013).

F. Wang, D. Qui, Z.-L. Liu, J. A. Taylor, M. A. Easton, and M.-X. Zhang, “The grain refinement mechanism of cast aluminium by zirconium,” Acta Mater. 61, 5636–5645 (2013).

J. Røyset and N. Ryum, “Scandium in aluminium alloys,” Int. Mater. Rev. 50, 19–44 (2005).

B. Forbord, H. Hallem, N. Ryum, and K. Marthinsen, “Precipitation and recrystallisation in Al–Mn–Zr with and without Sc,” Mater. Sci. Eng. 387–389, 936–939 (2004).

E. Nes, N. Ryum, and O. Hunderi, “On the Zener drag,” Acta Metall. 33, 11–22 (1985).

F. J. Humphreys and M. Hatherly, Recrystallization and Related Annealing Phenomena (Elsevier, Oxford, 2004).

V. V. Yashin, E. V. Aryshensky, R. F. Kawalla, V. N. Serebryany, and S. V. Rushchits, “Investigation impact of stressed state conditions and thermomechanical parameters on the texture and structure evolution in 1565ch aluminum alloy,” IOP Conf. Ser.: Mater. Sci. Eng. 156, 012 012 (2016).

S. Rushchits, E. Aryshenskii, R. Kawalla, and V. Serebryany, “Investigation of texture structure and mechanical properties evolution during hot deformation of 1565 aluminum alloy,” Mater. Sci. Forum 854, 73–78 (2016).

S. V. Rushchits, E. V. Aryshensky, S. M. Sosedkov, and A. M. Akhmed’yanov, “Modeling the hot deformation behavior of 1565ch aluminum alloy,” Key Eng. Mater. 684, 35–41 (2016).

J. O. Andersson, T. Helander, L. Hoglund, P. F. Shi, and B. Sundman, “Thermo-Calc and DICTRA, Computational tools for materials science,” CALPHAD: Comput. Coupling Phase Diagrams Thermochem. 26, 273–312 (2002).

Thermo-Calc Software TCAL4 Al-based alloy database, Version 4.0. Cited July 1, 2018.

E. Nes and H. E. Vatne, “The 40° 〈11〉 orientation relationship in recrystallization,” Z. Metallkd. 87, 6 (1996).

W. C. Liu, T. Zhai, and J. G. Morris, “Comparison of recrystallization and recrystallization textures in cold-rolled DC and CC AA 5182 aluminum alloys,” Mater. Sci. Eng., A 358, 84–93 (2003).

E. V. Aryshenskii, V. N. Serebryany, M. S. Tepterev, and A. F. Grechnikova, “Study of the laws of texture formation in the alloy 8011 during cold rolling and annealing,” Phys. Met. Metallogr. 116, 925–931 (2015).

O. Engler and S. Miller-Jupp, “Control of second-phase particles in the Al–Mg–Mn alloy AA 5083,” J. Alloys Compd. 689, 998–1010 (2016).

O. Engler, Z. Liu, and K. Kuhnke, “Impact of homogenization on particles in the Al–Mg–Mn alloy AA 5454–Experiment and simulation,” J. Alloys Compd. 560, 111–122 (2013).

Funding

This work was supported by the Russian Science Foundation (project no. 18-79-10099).

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated by T. Gapontseva

Rights and permissions

About this article

Cite this article

Tepterev, M.S., Aryshenskii, E.V., Guk, S.V. et al. Effect of Annealing Conditions on the Evolution of the Grain Structure and Intermetallic Phases in the Cold-Rolled Strip of Aluminum–Magnesium Alloy. Phys. Metals Metallogr. 121, 906–913 (2020). https://doi.org/10.1134/S0031918X20080128

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S0031918X20080128