Abstract

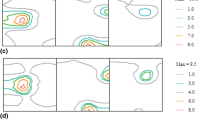

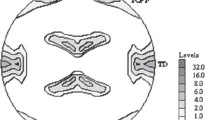

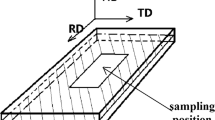

In this work the formation of strong recrystallization cube texture in heavily rolled Ni–9.3 at % W has been studied. During the cold rolling (also known as recovery-rolling) process the deformation texture of Ni–9.3 at % W alloy (further notated as Ni9W) transforms to Copper-type rolling texture, and after annealing, a sharp cube texture is generated. It is remarkably strong recrystallization cube texture, as high as 93 vol %, in metallic materials with low stacking fault energy. The formation mechanism of the cube texture is adopted for the rapid recovery of cube nuclei at the early stage of recrystallization as well as fast migration rate of high angle boundaries between cube grains and deformed microstructure at high temperature. Considering the cold rolling texture of Ni9W, oriented nucleation seems to play more important role in the cube texture formation process. In this article, the relationship between the deformation texture and recrystallization cube texture is discussed.

Similar content being viewed by others

REFERENCES

A. Goyal, R. Feenstra, M. Paranthaman, J. R. Thompson, B. Y. Kang, C. Cantoni, D. F. Lee, F. A. List, P. M. Martin, and E. Lara-Curzio, “Strengthened, biaxially textured Ni substrate with small alloying additions for coated conductor applications,” Phys. C 382, 251–262 (2002).

L. Ma, H. L. Suo, Y. Zhao, A. C. Wulff, Y. R. Liang, and J. C. Grivel, “Study on Fabrication of Ni–5 at % W Tapes for Coated Conductors from Cylinder Ingots,” IEEE Trans. Appl. Supercond. 25, 1–5 (2015).

A. A. Nikonov, “A study of the magnetoelastic effect of metal textured Ni–5 at % W tapes,” Phys. Met. Metallogr. 119, 6–17 (2018).

Y. Zhao, H. L. Suo, Y. H. Zhu, J. C. Grivel, M. Gao, L. Ma, R. F. Fan, M. Liu, Y. Ji, and M. L. Zhou, “Study on the formation of cubic texture in Ni–7 at % W alloy substrates by powder metallurgy routes,” Acta Mater. 57, 773–781 (2009).

J. Eickemeyer, R. Hühne, A. Güth, C. Rodig, U. Gaitzsch, J. Freudenberger, L. Schultz, and B. Holzapfel, “Textured Ni–9.0 at % W substrate tapes for YBCO-coated conductors,” Supercond. Sci. Technol. 23, 085012 (2010).

J. N. Liu, W. Liu, G. Y. Tang, and R. F. Zhu, “Fabrication of textured Ni–9.3 at % W substrate by electropulsing intermediate annealing method,” Phys. C 497, 119–122 (2014).

M. Gao, H. L. Suo, Y. Zhao, J. C. Grivel, Y. L. Cheng, L. Ma, R. Wang, P. K. Gao, J. H. Wang, and M. Liu, “Characterization and properties of an advanced composite substrate for YBCO-coated conductors,” Acta Mater. 58, 1299–1308 (2010).

U. Gaitzsch, J. Eickemeyer, C. Rodig, J. Freudenberger, B. Holzapfel, and L. Schultz, “Paramagnetic substrates for thin film superconductors: Ni–W and Ni–W–Cr,” Scr. Mater. 62, 512–515 (2010).

R. D. Doherty, “Recrystallization and texture,” Prog. Mater Sci. 42, 39–58 (1997).

V. S. Sarma, J. Eickemeyer, C. Mickel, L. Schultz, and B. Holzapfel, “On the cold rolling textures in some fcc Ni–W alloys,” Mater. Sci. Eng., A 380, 30–33 (2004).

R. D. Doherty, D. A. Hughes, F. J. Humphreys, J. J. Jonas, D. J. Jensen, M. E. Kassner, and W. E. King, “Current issues in recrystallization: a review,” Mater. Sci. Eng., A 238, 219–274 (1997).

U. Schmidt and K. Lücke, “Recrystallization Textures of silver, copper and α-brasses with different zinc-contents as a function of the rolling temperature,” Texture Cryst. Solids. 3, 85 (1979).

V. S. Sarma, J. Eickemeyer, L. Schultz, and B. Holzapfel, “Recrystallization texture and magnetization behavior of some FCC Ni–W alloys,” Scr. Mater. 50, 953–957 (2004).

R. Hielscher and H. Schaeben, “A novel pole figure inversion method: specification of the MTEX algorithm,” J. Appl. Crystallogr. 41, 1024–1037 (2010).

T. Leffers and R. K. Ray, “The brass-type texture and its deviation from the copper-type texture,” Prog. Mater Sci. 54, 351–396 (2009).

D. P. Field, L. T. Bradford, M. M. Nowell, and T. M. Lillo, “The role of annealing twins during recrystallization of Cu,” Acta Mater. 55, 4233–4241 (2007).

H. Paul, J. H. Driver, C. Maurice, and A. Piątkowski, “Recrystallization mechanisms of low stacking fault energy metals as characterized on model silver single crystals,” Acta Mater. 55, 833–847 (2007).

H. Tian, Y. Wang, L. Ma, M. Liu, and H. L. Suo, “Evolutions of the texture and microstructure of a heavily cold-rolled Ni9W alloy during recrystallization,” J. Mater. Res. 31, 2438–2444 (2016).

P. P. Bhattacharjee, R. K. Ray, and N. Tsuji, “Cold rolling and recrystallization textures of a Ni–5 at % W alloy,” Acta Mater. 57, 2166–2179 (2009).

A. A. Ridha and W. B. Hutchinson, “Recrystallization mechanisms and the origin of cube texture in copper,” Acta Metall. 30, 1929–1939 (1982).

D. P. Rodionov, I. V. Gervas’eva, Yu. V. Khlebnikova, V. A. Kazantsev, N. I. Vinogradova, and V. A. Sazonova, “Effect of recrystallization annealing on the formation of a perfect cube texture in fcc nickel Alloys,” Phys. Met. Metallogr. 111, 601–611 (2011).

R. K. Ray, W. B. Hutchinson, and B. J. Duggan, “A study of the nucleation of recrystallization using HVEM,” Acta Metall. 23, 831–840 (1975).

H. J. Bunge and U. Köhler, “Modeling primary recrystallization in fcc and bcc metals by oriented nucleation and growth with the statistical compromise model,” Textures Microstruct. 28, 3–4 (1997).

G. Gottstein, “Grain boundary migration in metals,” in Thermodynamics, Kinetics, Applications, Second Edition (CRC, 2009).

J. Hjelen, R. Ørsund, and E. Nes, “On the origin of recrystallization textures in aluminum,” Acta Metall. Mater. 39, 1377–1404 (1991).

I. Samajdar and R. D. Doherty, “Role of S[(123)〈634〉] orientations in the preferred nucleation of cube grains in recrystallization of FCC metals,” Scr. Metall. Mater. 32, 845–850 (1995).

B. J. Duggan, K. Lücke, G. Köhlhoff, and C. S. Lee, “On the origin of cube texture in copper,” Acta Metall. Mater. 41, 1921–1927 (1993).

K. G. Janssens, D. Olmsted, E. A. Holm, S. M. Foiles, S. J. Plimpton, and P. M. Derlet, “Computing the mobility of grain boundaries,” Nat. Mater. 5, 124–127 (2006).

A. L. Etter, M. H. Mathon, T. Baudin, V. Branger, and R. Penelle, “Influence of the cold rolled reduction on the stored energy and the recrystallization texture in a Fe–53% Ni alloy,” Scr. Mater. 46, 311–317 (2002).

S. Zaefferer, T. Baudin, and R. Penelle, “A study on the formation mechanisms of the cube recrystallization texture in cold rolled Fe–36% Ni alloys,” Acta Mater. 49, 1105–1122 (2001).

F. J. Humphreys and M. Hatherly, Recrystallization and Related Annealing Phenomena (Amsterdam, Elsevier, 1995), pp. 489–497.

Y. B. Zhang, A. Godfrey, Q. Liu, and W. Liu, “Analysis of the growth of individual grains during recrystallization in pure nickel,” Acta Mater. 57, 2631–2639 (2009).

ACKNOWLEDGMENTS

This work is financially supported by the National Natural Science Foundation of China (51571002, 51501096), by Beijing Natural Science Foundation (2172008), by General Program of Science and Technology Development Project of Beijing Municipal Education Commission of China (no. KM201810005010), by the Doctoral Program of Higher Education of Special Research Fund (20121103110012), by Beijing Municipal Natural Science Foundation B Type (KZ201310005003), and by Program of Beijing City and Beijing University of Technology.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Ji, Y.T., Suo, H.L., Ma, L. et al. Formation of Recrystallization Cube Texture in Highly Rolled Ni–9.3 at % W. Phys. Metals Metallogr. 121, 248–253 (2020). https://doi.org/10.1134/S0031918X20020180

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S0031918X20020180