Abstract

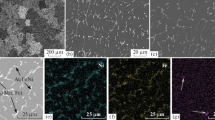

During high-strain-rate superplastic deformation, superplasticity indices, and the microstructure of two Al–Zn–Mg–Cu–Zr alloys with additions of nickel and iron, which contain equal volume fractions of eutectic particles of Al3Ni or Al9FeNi, have been compared. It has been shown that the alloys exhibit superplasticity with 300–800% elongations at the strain rates of 1 × 10–2–1 × 10–1 s–1. The differences in the kinetics of alloy recrystallization in the course of heating and deformation at different temperatures and rates of the superplastic deformation, which are related to the various parameters of the particles of the eutectic phases, have been found. At strain rates higher than 4 × 10–2, in the alloy with Fe and Ni, a partially nonrecrystallized structure is retained up to material failure and, in the alloy with Ni, a completely recrystallized structure is formed at rates of up to 1 × 10–1 s–1.

Similar content being viewed by others

References

T. G. Nieh, J. Wadsworth, and O. D. Sherby, Superplasticity in Metals and Ceramics (Cambridge Univ. Press, New York, 2005).

I. I. Novikov and V. K. Portnoi, Superplasticity of Alloys with Ultrafine Grain (Metallurgiya, Moscow, 1981) [in Russian].

J. C. Williams and E. A. Starke, “Progress in structural materials for aerospace systems,” Acta Mater. 51, 5775–5799 (2003).

T. Dursun, and C. Soutis, “Recent developments in advanced aircraft aluminum alloys,” Mater. Design 56, 862–871 (2014).

R. K. Mahidhara, “The fracture process in a finegrained superplastic 7475 Al alloy,” Mater. Design 15, 357–370 (1994).

Superplastic Forming of Advanced Metallic Materials. Methods and Applications, Ed. by G. Giuliano (Woodhead Publishing, Oxford, 2011).

H. Iwasaki, M. Mabuchi, and K. Higashi, “Plastic cavity growth during superplastic flow in AA7475 Al alloy containing a small amount of liquid,” Acta Mater. 49 (12), 2269–2275 (2001).

V. K. Portnoi, A. V. Mikhaylovskaya, A. Yu. Churyumov, Yu. V. Sinageikina, and A. D. Kotov, RF Patent 2491365, Byull. Izobr., 2013, no. 24.

A. D. Kotov, A. V. Mikhaylovskaya, and V. K. Portnoy, “Effect of the solid-solution composition on the superplasticity characteristics of Al–Zn–Mg–Cu–Ni–Zr alloys,” Phys. Met. Metallogr. 115 (7), 730–735 (2014).

A. V. Mikhaylovskaya, A. D. Kotov, A. V. Pozdniakov, and V. K. Portnoy, “A high-strength aluminum-based alloy with advanced superplasticity,” J. Alloys Compd. 599, 139–144 (2014).

A. D. Kotov, A. V. Mikhaylovskaya, M. S. Kishchik, A.A. Tsarkov, S. A. Aksenov, and V. K. Portnoy, “Superplasticity of high-strength Al-based alloys produced by thermomechanical treatment,” J. Alloys Compd. 688, 336–344 (2014).

L. F. Mondolfo, Aluminum Alloys: Structure and Properties, (Butterworths, Oxford, 1976).

A. D. Kotov, A. V. Mikhailovskaya, V. K. Portnoi, and T. B. Sagalova, “Formation of micrograin structure and superplastic state in alloys of the Al–Cu–Mg–Fe–Ni system,” Metal Sci. Heat Treat. 54, 340–344 (2012).

N. A. Belov, Phase Composition of Industrial and Perspective Aluminum Alloys (Mosk. Inst. Stali Splavov, Moscow, 2010) [in Russian].

A. V. Mikhaylovskaya, O. A. Yakovtseva, V. V. Cheverikin, A. D. Kotov, and V. K. Portnoy, “Superplastic behavior of Al–Mg–Zn–Zr–Sc–based alloys at high strain rates,” Mater. Sci. Eng., A 659, 225–233 (2016).

W. Feng, X. Baiqing, Z. Yongan, L. Zhihui, and L. Peiyue, “Microstructural characterization of an Al–Cu–Mg alloy containing Fe and Ni,” J. Alloys Compd. 487, 445–449 (2009).

A. D. Kotov, A. V. Mikhailovskaya, and V. K. Portnoy, “Superplasticity of alloy Al–11% Zn–3% Mg–0.8% Cu–0.3% Zr with Fe and Ni additives,” Metal Sci. Heat Treat. 55, 364–367 (2013).

A. D. Kotov, A. V. Mikhaylovskaya, I. S. Golovin, and V. K. Portnoy, “Fine-grained structure and superplasticity of Al–Cu–Mg–Fe–Ni alloys,” Mater. Sci. Forum. 735, 55–60 (2013).

F. J. Humphreys, and M. Hatherly, Recrystallization and Related Annealing Phenomena (Pergamon, Oxford, 1995).

Author information

Authors and Affiliations

Corresponding author

Additional information

Original Russian Text © A.D. Kotov, A.V. Mikhaylovskaya, A.A. Borisov, O.A. Yakovtseva, V.K. Portnoy, 2017, published in Fizika Metallov i Metallovedenie, 2017, Vol. 118, No. 9, pp. 958–966.

Rights and permissions

About this article

Cite this article

Kotov, A.D., Mikhaylovskaya, A.V., Borisov, A.A. et al. High-strain-rate superplasticity of the Al–Zn–Mg–Cu alloys with Fe and Ni additions. Phys. Metals Metallogr. 118, 913–921 (2017). https://doi.org/10.1134/S0031918X1709006X

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S0031918X1709006X