Abstract

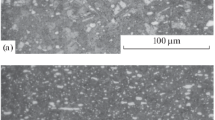

A thermodynamic simulation of phase equilibria in the Cu–Ni–Si–Cr system has been carried out using a FactSage program package (version 7.0). The structure and phase composition of the Cu–2.6Ni–0.6Si–0.6Cr bronze have been studied in the quenched and additionally aged (under various conditions) states. Precipitates of the chromium silicide Cr3Si have been revealed in the alloy both in the quenched and aged states. Particles of nickel silicide Ni2Si 0.05–0.5 μm in size appear upon the precipitation hardening both homogeneously and heterogeneously (on particles of previously formed chromium silicides). The microhardness (HV) and the electrical resistivity of the experimental samples have been determined after conducting processes of precipitation strengthening.

Similar content being viewed by others

References

A. P. Smiryagin, N. A. Smiryagina, and A. V. Belova, Industrial Non-ferrous Metals and Alloys. A Handbook), (Metallurgiya, Moscow, 1974), 3rd ed. [in Russian].

M. D. Teplitskii, A. K. Nikolaev, N. I. Revina, and V.M. Rozenberg, “Study of disperse particles in copper–nickel–silicon and copper–cobalt–silicon aging alloys,” Fiz. Met. Metalloved. 40, 1240–1243 (1975).

W. Sun, H. Xu, S. Liu, Y. Du, Z. Yuan, and B. Huang, “Phase equilibria of the Cu–Ni–Si system at 700°C,” J. Alloys Compd. 509, 9776–9781 (2011).

R. Monzen and Ch. Watanabe, “Microstructure and mechanical properties of Cu–Ni–Si alloys,” Mater. Sci. Eng., A {b483–d484}, 117–119 (2008).

A. Popa, S. Constantinescu, J. R. Groza, and I. Bock, “New high-temperature copper alloys,” J. Mater. Eng. Perf. 5, 695–698 (1996).

E. Lee, S. Han, K. Euh, S. Lim, and S. Kim, “Effect of Ti addition on tensile properties of Cu–Ni–Si alloys,” Met. Mater. Intern. 17, 569–576 (2011).

X.-P. Xiao, B.-Q. Xiong, Q.-S. Wang, G.-L. Xie, L.-J. Peng, and G.-X. Huang, “Microstructure and properties of Cu–Ni–Si–Zr alloy after thermomechanical treatments,” Rare Met. 32, 144–149 (2013).

K. S. Chenna, J. Srinath, A. K. Jha, B. Pant, S. C. Sharma, and K. M. George, “Microstructure and properties of a high-strength Cu–Ni–Si–Co–Zr alloy,” J. Mater. Eng. Perf. 22, 2115–2120 (2013).

S. Z. Han, J. H. Gu, J. H. Lee, Z. P. Que, J. H. Shin, S. H. Lim, and S. S. Kim, “Effect of V addition on hardness and electrical conductivity in Cu–Ni–Si alloys,” Met. Mater. Intern. 19, 637–641 (2013).

J. G. Kim, T. Y. Seong, J. H. Han, and A. J. Ardell, “Effect of heat treatment on precipitation behaviour in a Cu–Ni–Si–P alloy,” J. Mater. Sci. 21, 1357–1362 (1986).

A. Khereddine, L. F. Hadj, L. Djebala, H. Azzeddine, B. Alili, and D. Bradai, “X-ray diffraction analysis of cold-worked Cu–Ni–Si and Cu–Ni–Si–Cr alloys by Rietveld method,” Trans. Nonferrous Met. Soc. China 21, 482–487 (2011).

A. K. Nikolaev, A. I. Novikov, and V. M. Rozenberg, Chromic Bronzes (Metallurgiya, Moscow, 1983) [in Russian].

L. Jingguo, H. Jinliang, L. Ping, J. Xiaotian, Z. Dongmei, and Z. Xiao, “The effects of aging precipitation on the recrystallization of CuNiSiCr alloy,” J. Wuhan Univ. Technol. 20, 21–24 (2005).

Z. Rdzawski and J. Stobrawa, “Thermomechanical processing of Cu–Ni–Si–Cr–Mg alloy,” Mater. Sci. Technol. 9, 142–149 (1993).

J. Y. Cheng, B. B. Tang, F. X. Yu, and B. Shen, “Evaluation of nanoscaled precipitates in a Cu–Ni–Si–Cr alloy during aging,” J. Alloys Compd. 614, 189–195 (2014).

Phase Diagrams of Binary Metallic Systems, vol. 2, Ed. by N. P. Lyakishev (Mashinostroenie, Moscow, 1997).

Phase Diagrams of Binary Metallic Systems, vol. 3, Ed. by N. P. Lyakishev, (Mashinostroenie, Moscow, 1999).

O. V. Samoilova, E. A. Trofimov, G. G. Mihailov, and S. V. Ryaboshuk, “Phase equilibria that are realized in the copper corner of the Cu–Si–Ni phase diagram,” Rasplavy, no. 5, 59–65 (2013).

O. V. Samoilova, E. A. Trofimov, G. G. Mikhailov, and O. V. Zaitseva, “Phase equilibrium realizing in the copper angle of the phase diagram of the Cu–Cr–Si system,” Rasplavy, no. 2, 7–15 (2015).

O. V. Samoilova and E. A. Trofimov, “Phase equilibria in the copper-rich corner of the Cu–Ni–Si–Cr system,” Mater. Sci. Forum 870, 107–112 (2016).

N. T. Kareva, Yu. D. Koryagin, and G. I. Medvedeva, “Effect of different regimes of aging on the properties of the bronze BrNiCrSi alloy,” Izv. Vyssh. Ucheb. Zaved. Tsvetn. Metall., no. 6, 64–68 (1985).

V. M. Rozenberg and V. T. Dzutsev, Diagrams of Isothermal Decomposition in the Copper-Based Alloys: A Handbook (Metallurgiya, Moscow, 1989) [in Russian].

V. I. Zel’dovich, N. Y. Frolova, I. V. Khomskaya, and A. E. Kheifets, “Electron microscopic investigation of aging in the Cu–0.06% Zr alloy,” Phys. Met. Metallogr. 117, 710–718 (2016).

Author information

Authors and Affiliations

Corresponding author

Additional information

Original Russian Text © N.T. Kareva, I.L. Yakovleva, O.V. Samoilova, 2017, published in Fizika Metallov i Metallovedenie, 2017, Vol. 118, No. 8, pp. 836–842.

Rights and permissions

About this article

Cite this article

Kareva, N.T., Yakovleva, I.L. & Samoilova, O.V. On the precipitation strengthening of Cu–2.6Ni–0.6Si–0.6Cr bronzes. Phys. Metals Metallogr. 118, 795–801 (2017). https://doi.org/10.1134/S0031918X17080075

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S0031918X17080075