Abstract

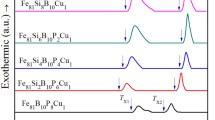

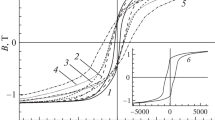

The process of the nanocrystallization of magnetically soft Fe72.5Cu1Nb2Mo1.5Si14B9 alloy has been studied using dilatometry and thermomagnetic analysis, together with structural investigations. It has been shown that the amount of nanocrystalline phase precipitated upon heating of the amorphous precursor is in good agreement with a shortening of the ribbon length in the course of crystallization. Thermal expansion at the different stages of heating and cooling depends on the structural and phase states, as well as on the magnetic state of the alloy. The numerical value of the coefficient of linear thermal expansion decreases with an increase in the fraction of the ferromagnetic crystalline phase.

Similar content being viewed by others

References

Y. Yoshizawa, S. Oguma, and K. Yamauchi, “New Febased soft magnetic alloys composed of ultrafine grain structure,” J. Appl. Phys. 64, 6044–6046 (1988).

G. Herzer, “Grain structure and magnetism of nanocrystalline ferromagnets,” IEEE Trans. Magn. 25, 3327–3329 (1989).

Y. Yoshizawa, “Nanocrystalline soft magnetic materials and their applications,” in Handbook of Advanced Magnetic Materials, Vol. 4: Properties and Applications, Ed. by Y. Liu, D. J. Sellmyer, and D. Shindo (Springer, New York, 2006), pp. 124–158.

G. Herzer, “Nanocrystalline soft magnetic alloys,” in Handbook of Magnetic Materials, Vol. 10, Ed. by K. H. J. Buschow (Elsevier, Amsterdam, 1997), pp. 415–462.

V. I. Keilin, V. Ya. Belozerov, and Yu. N. Starodubtsev, “Magnetic alloy for annealing in oxide medium and method of its production,” RF Patent 2009258, 1994.

V. Ya. Belozerov, Yu. N. Starodubtsev, V. I. Keilin, “Strip core from magnetic alloy on the base of iron,” RF Patent 2033649, 1995.

Yu. N. Starodubtsev and V. Ya. Belozerov, Magnetic Properties of Amorphous and Nanocrystalline Alloys (Izd. Ural. Univ., Ekaterinburg, 2002) [in Russian].

V. Tsepelev, V. Konashkov, Yu. N. Starodubtsev, V. Ya. Belozerov, and D. Gaipishevarov, “Optimum regime of heat treatment of soft magnetic amorphous materials,” IEEE Trans. Magn. 48, 1327–1330 (2012).

J. M. Silveyra, E. Illeková, P. Švec, D. Janickovic, A. Rosales-Rivera, and V. J. Cremaschi, “Phase transformations in Mo-doped FINEMETs,” Physica B 405, 2720–2725 (2010).

J. M. Silveyra, V. J. Cremaschi, D. Janickovic, P. Švec, and B. Arcondo, “Structural and magnetic study of Mo-doped FINEMET,” J. Magn. Magn. Mater. 323, 290–296 (2011).

B. N. Filippov, V. V. Shulika, A. V. Potapov, and N. F. Vil’danova, “Magnetic properties and temperature stability of a molybdenum-doped FINEMENTtype alloy,” Tech. Phys. 59, 373–377 (2014).

Y. C. Niu, X. F. Bian, V. M. Wang, S. F. Jin, G. H. Li, F. M. Chu, and W. G. Zhang, “The peculiarity of contraction in the primary crystallization of amorphous Fe73.5Nb3CuSi13,5B9 alloy,” J. Alloys Compd. 433, 296–301 (2007).

J. M. Silveyra, V. J. Cremaschi, G. Vlasák, E. Illeková, D. Janickovic, and P. Švec, “Magnetostrictive behavior of Fe73.5Si13.5B9Nb(3–x)MoxCu alloys,” J. Magn. Magn. Mater. 322, 2350–2354 (2010).

O. Kubaschewski, Iron—Binary Phase Diagrams (Springer, Berlin, 1982).

C. L. Chien, D. Musser, E. M. Gyorgy, R. C. Sherwood, H. S. Chen, F. E. Luborsky, and J. L. Walter, “Magnetic properties of amorphous FexB(100–x) (72 = x = 86) and crystalline Fe3B,” Phys. Rev. B: Solid State 20, 283–295 (1979).

J. B. Jeffries and N. Hershkowitz, “Temperature dependence of the hyperfine interactions of FeB,” Phys. Lett. 30, 187–188 (1969).

V. A. Barinov, V. I. Voronin, V. A. Kazantsev, V. A. Tsurin, V. V. Fedorenko, S. I. Novikov, and V. T. Surikov, “Structure and magnetic properties of metastable Fe–B phase,” Phys. Met. Metallogr. 100, 456–467 (2005).

W. A. Chen and P. L. Ryder, “X-ray and differential scanning calorimetry study of the crystallization of amorphous Fe73.5CuNb3Si13,5B9 alloy,” Mater. Sci. Eng., B 34, 204–209 (1995).

J. M. Borrego, C. F. Conde, and A. Conde, “Thermomagnetic study of devitrification in Fe–Si–B–Cu–Nb(–X) alloys,” Philos. Mag. Lett. 80, 359–365 (2000).

R. Gerling, F. P. Schimansky, and R. Wagner, “Restoration of the ductility of thermally embrittled amorphous alloys under neutron-irradiation,” Acta Metall. 35, 1001–1006 (1987).

Y. C. Niu, X. E. Bian, and W. M. Wang, “Origin of ductile–brittle transition of amorphous Fe78Si9B13 ribbon during low temperature annealing,” J. Non-Cryst. Solids 341, 40–45 (2004).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Tsepelev, V.S., Starodubtsev, Y.N., Zelenin, V.A. et al. Dilatometric analysis of the process of the nanocrystallization of Fe72.5Cu1Nb2Mo1.5Si14B9 soft magnetic alloy. Phys. Metals Metallogr. 118, 553–557 (2017). https://doi.org/10.1134/S0031918X17060096

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S0031918X17060096