Abstract

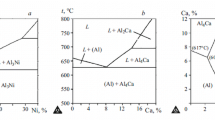

The structure and phase composition of Al–Ca–Mg–Sc alloys containing 0.3 wt % Sc, up to 10 wt % Ca, and up to 10 wt % Mg have been investigated in the cast state and state after heat treatment. It has been shown that only binary phases Al4Ca, Al3Sc, and Al3Mg2 can be in equilibrium with the aluminum solid solution. It has been found that the maximum strengthening effect caused by the precipitation of Al3Sc nanoparticles for all investigated alloys is attained after annealing at 300–350°C.

Similar content being viewed by others

References

L. S. Toropova, D. G. Eskin, M. L. Kharakterova, and T. V. Dobatkina, Advanced Aluminum Alloys Containing Scandium: Structure and Properties (Gordon and Breach Science, Amsterdam, 1998).

Yu. A. Filatov, “Deformable alloys based on the Al–Mg–Sc system,” Metal Sci. Heat Treat. 38, 271–274 (1996).

V. V. Zakharov, V. I. Elagin, T. D. Rostova, and Yu. A. Filatov, “Metal science principles of alloying aluminum alloys with scandium,” Tekhnol. Legk. Splavov, No. 1, 67–73 (2010).

J. Øyset and N. Ryum, “Scandium in aluminum alloys,” Int. Mater. Rev. 50, 19–44 (2005).

E. A. Marquis and D. N. Seidman, “Nanoscale structural evolution of Al3Sc precipitates in Al(Sc) alloys,” Acta Mater. 49, 1909–1919 (2001).

S. Costa, H. Puga, J. Barbosa, and A. M. P. Pinto, “The effect of Sc additions on the microstructure and age hardening behavior of as cast Al–Sc alloys,” Mater. Des. 42, 347–352 (2012).

D. N. Seidman, E. A. Marquis, and D. C. Dunand, “Precipitation strengthening at ambient and elevated temperatures of heat-treatable Al(Sc) alloys,” Acta Mater. 50, 4021–4035 (2002).

V. S. Zolotorevskii and N. A. Belov, Metal Science of Casting Aluminum Alloys (MISiS, Moscow, 2005) [in Russian].

L. F. Mondolfo, Aluminum Alloys: Structure and Properties (Butterworths, London, 1976; Metallurgiya, Moscow, 1979).

I. J. Polmear, Light Metals: From Traditional Alloys to Nanocrystals, 4th ed. (Elsevier, 2006).

Properties of Elements. A Handbook. Book 1, Ed. by M. E. Drits (Metallurgiya, Moscow, 1997) [in Russian].

N. A. Belov, A. N. Alabin, and I. A. Matveeva, “Optimization of phase composition of Al–Cu–Mn–Zr–Sc alloys for rolled products without requirement for solution treatment and quenching,” J. Alloys Compd. 583, 206–213 (2014).

www.thermocalc.com.

Author information

Authors and Affiliations

Corresponding author

Additional information

Original Russian Text © N.A. Belov, E.A. Naumova, T.A. Bazlova, E.V. Alekseeva, 2016, published in Fizika Metallov i Metallovedenie, 2016, Vol. 117, No. 2, pp. 196–203.

Rights and permissions

About this article

Cite this article

Belov, N.A., Naumova, E.A., Bazlova, T.A. et al. Structure, phase composition, and strengthening of cast Al–Ca–Mg–Sc alloys. Phys. Metals Metallogr. 117, 188–194 (2016). https://doi.org/10.1134/S0031918X16020046

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S0031918X16020046