Abstract—

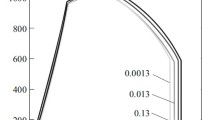

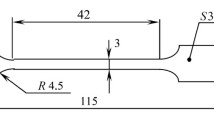

Tensile stresses present in the pipe steels exposed to corrosive environment can result in the corrosion cracking of the pipe material. The standard procedure used for assessing the susceptibility of steels to stress corrosion cracking (for about 720 h) often does not fully provide insight into the characteristics of the material. The goal of the study is to develop a more rapid test procedure, which can provide reliable and complete information about the material placed in a corrosive environment under stress. Accelerated test for stress corrosion cracking of pipe steels with a relative strain rate of ~10–6 s–1 is proposed. The results of testing two materials at different deformation rates placed in different corrosive environments are presented. The tensile diagrams of the specimens tested in air and corrosive environments containing hydrogen sulfide and carbon dioxide, as well as the measurement of the relative elongation and relative contraction of fractured specimens, were used to determine a degree of the susceptibility of the pipe steels, which differ in the strength characteristics to stress corrosion cracking. It is shown that the degree of susceptibility of steel to stress corrosion cracking depends on the characteristics of the corrosive environment and the strength of the pipe steel. Tests under low rate of loading compared to tests with static load of the specimens revealed reduced duration of analysis from 720–1000 to 25–100 h.

Similar content being viewed by others

REFERENCES

Azhogin, F.F., Korozionnoe rastreskivanie i zashchita vysokoprochnykh stalei (Corrosion Cracking and Protection of High-Strength Steels), Moscow: Metallurgiya, 1974.

Karpenko, G.V. and Vasilenko, I.I., Korrozionnoe rastreskianie stalei (Corrosion Cracking of Steels), Kiev: Tekhnika, 1971.

Sinyavskii, V.S. and Lukina, S.I., Corrosion cracking of titanium alloys in neutral aqueous solutions, Tekhnol. Legk. Splavov, 1980, no. 8, pp. 72–83.

Bobylev, A.V., Korrozionnoe rastreskivanie latuni (Corrosion Cracking of Brass), Moscow: Metallurgizdat, 1956.

Beloglazov, S.M., Navodorozhivanie stali pri elektrokhimicheskikh protsessakh (Steel Hydrogenation during Electrochemical Processes), Leningrad: Leningr. Gos. Univ., 1975.

Shreider, L.V., Shparber, I.S., and Archakov, Yu.I., Vliyanie vodoroda na neftyanoe i khimicheskoe oborudovanie (The Effect of Hydrogen on Petroleum and Chemical Equipment), Moscow: Mashinostroenie, 1976.

Perez, T.I., Corrosion in the oil and gas industry: an increasing challenge for materials, JOM, 2013, vol. 65, no. 8, pp. 1033–1042. https://doi.org/10.1007/s11837-013-0675-3

Burke, P.A., Recent progress in the understanding of CO2 corrosion, in Advances in CO 2 Corrosion, Houston, TX: Natl. Assoc. Corros. Eng., 1984, vol. 1, pp. 3–9.

Schmitt, G., Fundamental aspects of CO2 corrosion, in Advances in CO 2 Corrosion, Houston, TX: Natl. Assoc. Corros. Eng., 1984, vol. 1, pp. 10–19.

Schmitt, G. and Horstemeier, M., Fundamental aspects of CO2 metal loss corrosion, Part II: Influence of different parameters on CO2 corrosion mechanisms, Proc. NACE-Corrosion 2006 Meeting, March 11–16, 2006, San Diego, Houston, TX: Natl. Assoc. Corros. Eng., 2006, no. NACE-06112.

Schmitt, G. and Schierkmann, G., Corrosion cracking of steel in the system CO2/H2O, Proc. 8th Int. Congr. on Metallic Corrosion, Frankfurt on Main: Deutsh. Ges. Chem. App., 1981, vol. 1, pp. 426.

TM0177-2016-SG: Laboratory Testing of Metals for Resistance to Sulfide Stress Cracking and Stress Corrosion Cracking in H 2 S Environments, Houston, TX: NACE Int., 2016, p. 61.

GOST (State Standard) 9.903-81: Unified System of Corrosion and Ageing Protection. High-Strength Steels and Alloys. Accelerated Test Methods for Corrosion Cracking, Moscow: Izd. Standartov, 1982.

Kharkov, A.A., Nemchikova, L.G., Mikhnevich, A.P., and Bilina, S.Yu., Evaluation of the tendency of steel to corrosion cracking when tested with a slow strain rate, Tekhnol. Sudostr., 1990, no. 3, pp. 10–13.

Oryshchenko, A.S., Mushnikova, S.Y., Kharkov, A.A., and Kalinin, G.Y., Study of stress corrosion cracking of austenitic steels in seawater, Proc. European Corrosion Congr., EUROCORR 2010, Moscow, 2010.

Parkins, R.N., The controlling parameters in stress corrosion cracking, Proc. Fifth Symp. on Line Pipe Research, Chantilly, VA: Pipeline Res. Counc. Int., 1974, no. L30174.

ASTM G129: Standard Practice for Slow Strain Rate Testing to Evaluate the Susceptibility of Metallic Materials to Environmentally Assisted Cracking, West Conshohocken, PA: ASTM Int., 2013.

Corrosion, Shreir, L.L., Ed., London: Newnes-Butterworths, 1976.

Funding

The work is partially funded by the Ministry of Science and Higher Education of the Russian Federation as part of World-class Research Center program: Advanced Digital Technologies, grant no. 075-15-2020-934 dated to November 17, 2020.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Alkhimenko, A.A., Kharkov, A.A., Shemyakinskiy, B.A. et al. Development of the Methodology of Accelerated Testing of Oil-Gas Pipe Steels for Stress Corrosion Cracking. Inorg Mater 57, 1541–1546 (2021). https://doi.org/10.1134/S0020168521150024

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S0020168521150024