Abstract—

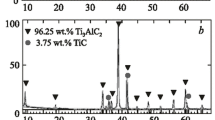

We have studied solid-state reactions of unmilled and ball-milled iridium powders with SiC and WC powders in the temperature range 800–1400°C. Interaction of iridium with SiC leads to the formation of various iridium silicides, whose composition and concentration depend on the reaction mixture treatment temperature and iridium particle size. Interaction of iridium with WC leads to the formation of a WxIr1–x intermetallic phase with a broad homogeneity range. Mechanical treatment of iridium powder has been shown to markedly speed up solid-state reactions between the iridium and refractory carbides, primarily owing to the associated increase in the specific surface area of the iridium and the accumulation of structural defects.

Similar content being viewed by others

REFERENCES

Yamabe-Mitarai, Y. and Murakami, H., Mechanical properties at 2223 K and oxidation behavior of Ir alloys, Intermetallics, 2014, vol. 48, pp. 86–92.https://doi.org/10.1016/j.intermet.2013.09.014

Ohriner, E. and Yang, Y., Thermodynamic analysis on interactions of silicon dioxide with iridium during module reduction and monitoring treatment, J. Phase Equilib. Diffus., 2018, vol. 39, pp. 532–537.https://doi.org/10.1007/s11669-018-0637-0

Lozanov, V.V., Baklanova, N.I., Bulina, N.V., and Titov, A.T., New ablation-resistant material candidate for hypersonic applications: synthesis, composition, and oxidation resistance of HfIr3-based solid solution, ACS Appl. Mater. Interfaces, 2018, vol. 10, no. 15, pp. 13062–13072.https://doi.org/10.1021/acsami.8b01418

Cockeram, B.V., US Patent Application 20190329519, 2019.

Wang, Y., Zhang, L., Yin, K., Zhang, J., Gao, H., Liu, N., Peng, Z., and Zhang, Z., Nanoporous iridium-based alloy nanowires as highly efficient electrocatalysts toward acidic oxygen evolution reaction, ACS Appl. Mater. Interfaces, 2019, vol. 11, no. 43, pp. 39728–39736.https://doi.org/10.1021/acsami.9b09412

Production techniques and quality control of sealed radioactive sources of palladium-103, iodine-125, iridium-192 and ytterbium-169, Final Report no. IAEA-TECDOC-1512, IAEA, 2006. https://www-pub.iaea.org/MTCD/publications/PDF/ te_1512_web.pdf

Lozanov, V.V., Il’in, I.Yu., Morozova, N.B., Trubin, S.V., and Baklanova, N.I., Chemical vapor deposition of an iridium phase on hafnium carbide and tantalum carbide, Russ. J. Inorg. Chem., 2020, vol. 65, no. 11, pp. 1781–1788.https://doi.org/10.1134/S0036023620110108

Zaikov, Yu.P., Isakov, A.V., Apisarov, A.P., and Nikitina, A.O., Electrochemical synthesis of iridium powder with a large specific surface area, Rasplavy, 2016, vol. 6, pp. 1–10.

Aleksandrov, E.P., Aleksandrov, D.E., and Kazakov, A.S., Properties and application of metallic iridium nanopowder, Fiziko-khimicheskie aspekty predel’nykh sostoyanii i strukturnykh prevrashchenii v sploshnykh sredakh, materialakh i tekhnicheskikh sistemakh (Physicochemical Aspects of Boundary States and Structural Transformations in Continuous Media, Materials, and Engineering Systems), Petrov, Yu.V., Ed., St. Petersburg: Politekhnika, 2019, issue 3, pp. 138–145.https://doi.org/10.25960/7325-1150-5-138

Scholl, R., Fister, D., Spieker, C., and Ngo Ding Lam, RF Patent 2367542, 2009.

Pavlov, E.A., Mal’tsev, E.V., and Gushchinskii, A.A., Intensification of the stripping of refractory refining middlings: Part 1: Effect of mechanical activation on the structure and reactivity of minute platinum associate metals and materials containing them, Izv. Samarsk. Nauchn. Tsentra Ross. Akad. Nauk, 2013, vol. 15, no. 6–2, pp. 432–437.

McCormick, P.J. and Tzuzuki, T., US Patent 6503475, 2003.

Ichiyanagi, K., Takagi, S., Kawai, N., Fukaya, R., Nozawa, S., Nakamura, K.G., Liss, K.-D., Kimura, M., and Adachi, S., Microstructural deformation process of shock-compressed polycrystalline aluminum, Sci. Rep., 2019, vol. 9, paper 7604. https://doi.org/doi 10.1038/s41598-019-43876-2

Sha, J.B. and Yamabe-Mitarai, Y., Phase and microstructural evolution of Ir–Si binary alloys with fcc/silicide structure, Intermetallics, 2006, vol. 14, pp. 672–684. https://doi.org/doi 10.1016/j.intermet.2005.11.005

Rybin, V., Lozanov, V., Utkin, A., Matvienko, A., and Baklanova, N., The formation of disordered intermetallic phase during the solid-state interaction of WC with Ir, J. Alloys Compd., 2019, vol. 775, pp. 503–510.https://doi.org/10.1016/j.jallcom.2018.10.118

Rapperport, E.J. and Smith, M.F., Refractory metal constitution diagrams, Technical Report no. WADD TR, pp. 60–132, part II, Wright-Patterson Air Force Base, 1962. https://archive.org/stream/DTIC_AD0287548

Huang, Y.-Y., Wu, B., Li, F., Chen, L.-L., Deng, Z.-X., and Chang, K., First-principles and CALPHAD-type study of the Ir–Mo and Ir–W systems, J. Min. Metall., Sect. B, 2020, vol. 56, no. 1, pp. 109–118. https://doi.org/10.2298/JMMB190211001H

ACKNOWLEDGMENTS

We are grateful to A.T. Titov for the electron-microscopic work and to A.V. Ukhina for collecting the X-ray diffraction patterns of the samples.

Funding

This work was supported by the Russian Science Foundation, project no. 18-19-00075.

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated by O. Tsarev

Rights and permissions

About this article

Cite this article

Bannykh, D.A., Golosov, M.A., Lozanov, V.V. et al. Effect of Mechanical Activation of Iridium on Its Reaction with Refractory Carbides. Inorg Mater 57, 879–886 (2021). https://doi.org/10.1134/S0020168521090028

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S0020168521090028