Abstract—

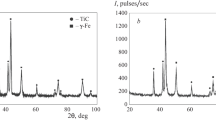

Using nonvacuum electron beam cladding of a Cr3C2 + TiC powder mixture, we have produced coatings on low-carbon steel in a wide range of processing conditions. The coatings and reference samples have been tested in corrosion and wear resistance. The results demonstrate that the coating obtained at a deposited surface energy density W = 8.8 kJ/cm2 has the highest corrosion resistance, which is due to the increase in the chromium concentration in the cladded layer to 16%. The wear resistance of the coatings has been shown to be influenced by the number and size of titanium carbide particles. The highest wear resistance is offered by the coating produced at W = 10.0 kJ/cm2.

Similar content being viewed by others

REFERENCES

Fominskii, L.P. and Kazanskii, V.V., Preparation of powder coatings by relativistic electron beam cladding, Svar. Proizvod., 1985, no. 5, pp. 13–15.

Poletika, I.M., Borisov, M.D., Kraev, G.V., Vaisman, A.F., Golkovski, M.G., and Durakov, V.A., Principles of relativistic electron beam alloying of steel, Izv. Vyssh. Uchebn. Zaved., Fiz., 1996, no. 3, pp. 115–125.

Bataev, I.A., Bataev, A.A., Golkovski, M.G., Krivizhenko, D.S., Losinskaya, A.A., and Lenivtseva, O.G., Structure of surface layers produced by non-vacuum electron beam boriding, Appl. Surf. Sci., 2013, vol. 284, pp. 472–481.

Poletika, I.M., Ivanov, Yu.F., Golkovski, M.G., Krylova, T.A., and Perovskaya, M.V., Structure and properties of corrosion-resistant coatings produced by electron beam welding in air, Metalloved. Term. Obrab. Met., 2009, no. 12, pp. 33–39.

Mul’, D.O., Drobyaz, E.A., Chakin, I.K., Samoilenko, V.V., Lozhkin, V.S., and Dostavalov, R.A., Structure and properties of steel coated with titanium, tantalum, molybdenum, and graphite powders by nonvacuum electron beam cladding, Obrab. Met. (Tekhnol., Oborudovanie, Instrum.), 2013, no. 3 (60), pp. 115–120.

Yun, E., Kim, Y.C., Lee, S., and Kim, N.J., Correlation of microstructure with hardness and wear resistance in (TiC, SiC)/stainless steel surface composites fabricated by high-energy electron-beam irradiation, Metall. Mater. Trans. A, 2004, vol. 35, no. 13, pp. 1029–1038.

GOST (State Standard) 9.905-82: Corrosion Test Methods. General Requirements, 1982.

GOST (State Standard) 9.908-85: Methods for Determination of Corrosion and Corrosion Resistance Indices, 1985.

GOST (State Standard) 23.208-79: Ensuring of Wear Resistance of Products. Wear Resistance Testing of Materials by Friction against Loosely Fixed Avrasive Particles, 1979.

Krylova, T.A., Ivanov, K.V., and Ovcharenko, V.E., Structure, phase state, and hardness of coatings produced by high-energy electron beam cladding of Cr3C2 and TiC powders on low-carbon steel, Fiz. Khim. Obrab. Mater., 2018, no. 3, pp. 43–49.

Vinogradov, V.N. and Kolokol’nikov, M.G., Abrazivnoe iznashivanie (Abrasive Wear), Moscow: Mashinostroenie, 1990, p. 224.

Krylova, T.A., Ivanov, K.V., and Ovcharenko, V.E., The structure, microhardness and wear resistance of coatings obtained through non-vacuum electron beam cladding of chromium and titanium carbides on low carbon steel, Mater. Sci. Forum, 2018, vol. 927, pp. 13–19.

Kochergin, V.P., Zashchita metallov ot korrozii v ionnykh rasplavakh i rastvorakh elektrolitov: Uchebnoe posobie (Corrosion Protection of Metals in Ionic Melts and Electrolyte Solutions: A Learning Guide), Yekaterinburg: Ural. Gos. Univ., 1991.

ACKNOWLEDGMENTS

We are grateful to M.G. Golkovski (Budker Institute of Nuclear Physics, Siberian Branch, Russian Academy of Sciences) for his assistance in the electron beam welding work.

Funding

This work was supported by the State Academies of Sciences Basic Research Program (2013–2020), project no. 23.2.1.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Krylova, T.A., Ivanov, K.V., Chumakov, Y.A. et al. Corrosion and Wear Resistance of Coatings Produced by Nonvacuum Electron Beam Cladding of Refractory Carbides on Low-Carbon Steel. Inorg Mater 56, 328–332 (2020). https://doi.org/10.1134/S0020168520030097

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S0020168520030097