Abstract

An experimental study of the main factors affecting the accuracy of oxygen and carbon isotopic analysis in carbonates dispersed in silicate matrix is carried out. Artificial 1, 2, 5, and 10% mixtures of quartz with carbonates with different isotopic parameters (KH-2, Ko, MCA-8) were analyzed by continuous flow isotope ratio mass spectrometry (CF IRMS). It is established that, in addition to the influence of the instrumental nonlinearity, the results are affected by two factors: trace amounts of CO2, constantly present in the system (the blank effect) and the presence of chemically neutral silicate particles (the matrix effect). The blank effect depends on the isotopic parameters of the sample and has very little influence on the estimated carbonate content in the rock. The matrix effect, on the contrary, strongly affects the estimated carbonate content, and produces the isotopic shift towards underestimated contents of heavy 13C and 18O isotopes. It is shown that this effect is related to the processes occurring near the CO2–acid–quartz interface, which are accompanied by kinetic fractionation of carbon and oxygen isotopes. Both effects are dependent on the amount of silicate matrix in the system and most clearly manifested during analysis of carbonate-poor rocks. When the carbonate content in the rock is about 1–2%, deviations from the true δ13C and δ18O values can reach the first ppm, while carbonate content obtained by chromatographic peak calibration can be underestimated by 20–40%.

Similar content being viewed by others

Explore related subjects

Find the latest articles, discoveries, and news in related topics.Avoid common mistakes on your manuscript.

INTRODUCTION

Carbon and oxygen (δ13C, δ18O) isotopic analysis of carbonates decomposed in orthophosphoric acid is conventional for isotopic geochemistry and was developed more than 70 years ago (McCrea, 1950). However, the problems associated with the analysis of carbonates dispersed in silicate rocks are still poorly understood. This type of analysis is relevant to, e.g., igneous rocks that were contaminated, at some point of their history, by sedimentary matter (Zhao et al., 2001; Dubinina et al., 2010); products of metamorphism involving carbon dioxide; or rocks processed with aqueous carbonate fluid, e.g., during ore formation (Zheng et al., 2003, 2000; Dubinina et al., 2019). Analysis of silicate–carbonate material is also pertinent to studies of kimberlites (Giuliani et al., 2014; Galimov, 1991; etc.) and serpentinized ultramafic rocks of oceanic crust (Alt and Shanks III, 2006). The carbonate content in such rocks can vary from the first percent to hundredths of a percent; i.e., it is required to analyze samples where carbonates are surrounded by a large amount of silicate matrix. Despite such a wide range of applications, not much has been done to study limitations of the method, except for works devoted to selective acid decomposition of carbonates (Walters et al., 1972; Spotl and Wennemann, 2003; Rosenbaum and Sheppard, 1986; Liu et al., 2018; Du and Song, 2020; Sreenivasan et al., 2023 etc.).

Isotopic analysis of small carbonate contents can be performed using the modern method of continuous helium flow isotope ratio mass spectrometry (CF IRMS), which allows very small amounts of substance to be analyzed (Brand, 1996, 2004; Breitenbach and Bernasconi, 2011; Paul and Skrzypek, 2007; Skrzypek and Paul, 2006; Nelson, 2000; Revesz and Landwehr, 2002; Werner and Band, 2001). Application of the standard variant GasBenchII (Thermo, Germany) provides isotopic analysis of carbonate carbon and oxygen from 100- to 250-μg samples in terms of pure calcium carbonate (Finnigan, 2004); the improved version reduces that amount to 50 μg (Fiebig et al., 2005; Velivetskaya et al., 2009). An additional advantage of the CF IRMS method is the possibility of estimating the amount of analyzed gas (Zha et al., 2010).

Silicate rocks containing trace amounts of carbonate are analyzed in a bulk sample ground to a fine powder. To provide the necessary amount of carbonate substance, the sample weight is increased by tens and even hundreds of times. As a result, there are a large number of silicate matrix particles in the vicinity of the reaction occurring between carbonate and acid. The particles can affect the accuracy of both isotopic analysis and carbonate content determination. Obviously, the results of the analysis in this case are affected by several factors, studied to varying degrees. First of all, it is easily controlled instrumental nonlinearity of measurements of chromatographic peaks of different area and breadth (Spotl and Vennemann, 2003). The effect of blank, the residual amounts of CO2 and water adsorbed on the vial and sample surface, is less studied (Zha et al., 2010; Nelson, 2000), and the effect of the silicate matrix, which is present directly in the reaction zone of carbonate with orthophosphoric acid, is almost completely unknown (Zha et al., 2017; Sreenivasan et al., 2023). The silicate matrix is inert with respect to orthophosphoric acid, but, since it is a highly dispersed system with a large surface area, it can play a special and very prominent role. Apart from the obvious fact that a large amount of matrix should lead to an increased blank, the matrix itself may exhibit specific effects and, while the effect of blank is obvious and can be considered as the presence of trace amounts of extraneous CO2 gas in the analyzed sample, the role of chemically neutral matrix in the “silicate–CO2–orthophosphoric acid” system is largely unexplored.

A detailed study of artificial silicate–carbonate mixtures (Zha et al., 2010) showed that the accuracy of determining δ13C and δ18O drops in the presence of a significant amount of silicates; the measured values are systematically biased from the true ones. This conclusion was based on an analysis of mixtures prepared from the same carbonate standard with quartz (Zha et al., 2010). The authors established a threshold sample size (≈70 μg of pure CaCO3) and identified bias in δ18O and δ13C values measured from lesser amounts of material for the influence of traces of CO2 and moisture adsorbed on the sample surface.

Despite abundant evidence of the matrix effect manifested in analysis of multicomponent carbonate and silicate–carbonate mixtures (Walters et al., 1972; Liu et al., 2018; Zha et al., 2017; Al-Aasm et al., 1990), this factor has not been specifically studied. Experiments performed on artificial carbonate–silicate mixtures (Zha et al., 2010) did not isolate this effect because the mixtures were prepared from the same carbonate, making it impossible to distinguish the blank effect (impurities of residual CO2) from the matrix effect (presence of “neutral” silicate or carbonate particles in the analytical space).

The aim of this work is to evaluate each factor influencing the results of analysis of carbonates in a silicate matrix. For this purpose, we have studied silicate–carbonate mixtures prepared from carbonates with different δ13C and δ18O values. Obviously, the blank effect should manifest itself in an isotope shift toward specific values of δ13C and δ18O, and this would be differently reflected in carbonates with different isotopic parameters. The matrix effect, being kinetic in nature, should not depend on the isotopic parameters of the mixtures. Thus, it is possible to distinguish between the blank effect and the matrix effect. The effect of instrumental nonlinearity associated with the measurement of small amounts of analyzed gas should also be independent of isotopic parameters, but this effect can be reliably calibrated and accounted for.

METHODOLOGY OF THE EXPERIMENT AND ANALYSIS OF CARBONATE–SILICATE MIXTURES

Experimental Mixtures

Laboratory standard quartz (Polaris, δ18O = 13.0‰) was used as a silicate matrix for the preparation of experimental mixtures. Carbonates were represented by three samples, which were previously often used as reference substances: KH-2 limestone and Ko and MSA-8 calcites. Their isotopic characteristics are summarized in Table 1. Each of these samples was used to prepare mixtures with 1, 2, 5, and 10 wt % carbonate content. The mixtures were homogenized by grinding under a layer of alcohol in a polished agate mortar to a fine powder. After grinding, the mixtures were dried in a drying oven at 105°С and stored in an desiccator. Prior to analysis, the prepared samples were additionally baked (105°С, 2 h) directly in borosilicate glass vials. The hot vials were hermetically sealed with standard rubber septa lids and placed in the measuring unit of the PAL autosampler, after which standard carbonate isotope analysis in continuous helium flow was performed using the GasBenchII option. The samples of pure carbonates used for preparing the silicate–carbonate mixtures were included in respective measurement series. The sample weights of pure carbonate were chosen as far as possible with regard to the expected range of the CO2 amount, released from the silicate–carbonate mixtures. The data obtained for the pure carbonates were used to calibrate the area of the chromatographic peaks to calculate the amount CO2 gas coming from the sample mixtures. The characteristics of the mixtures and analytical results are summarized in Table 2.

Algorithm for Isotope Measurements

We used a set of equipment (Thermo, Germany), in which the GasBenchII device with a PAL autosampler is connected to a Delta V+ mass spectrometer via a ConFlo IV gas switch. Oxygen- and carbon-isotope analysis of carbonates by CF IRMS is based on their chemical decomposition with orthophosphoric acid:

In contrast to conventional techniques based on vacuum purification of substances and reaction volumes, methods exploiting a continuous helium flow utilize purging of analytical volumes with a carrier gas (Paul and Skrzypek, 2006). We used high-purity helium (grade 6.0) at a flow rate of 180 mL/min for 360 s, after which specially prepared 105% orthophosphoric acid prevacuumed for 48 h was introduced into the vials (Burman et al., 2005). The acid was introduced manually along the vial wall, avoiding vertical drops and sputtering the sample. The amount of acid ensured complete coverage of the sample. An amount of 0.05 mL was added to pure carbonates, 0.1 mL to mixtures weighing up to 3 mg, and 0.2 mL to samples above 3 mg. The reaction time was 2 h at 70°C. As the reaction progressed, the released CO2 gas flowed through the acid–gas interface into the free space of the vial filled with helium. At the end of the reaction, a portion of helium containing CO2 extracted from the sample was withdrawn by a special measuring needle (Thermo) and fed into a moisture removal system (Nafion trap) and, then, into a chromatographic column (PoraPlot Q) heated to 70°. After chromatographic purification, a portion of CO2 is delivered with helium flow through a ConFlo IV gas switch to the measurement system of a Delta V+ mass spectrometer.

Analytical procedure included registration of background intensities, adjustment to the peak center, triple input of the standard CO2 and triple input of the analyzed gas portions. The errors of repeatedly measured homogeneous carbonate standards (NBS 19, NBS 18) was ±0.05 and ±0.1‰ (1σ) for δ13C and δ18O, respectively. Calibration of the results against the international scales V-SMOW (δ18O values) and V-PDB (δ13C values) was carried out by three-point normalization (Paul et al., 2007) using the international standards NBS-18 and NBS-19 and internal standard ATS (repeatedly certified homogeneous natural calcite) in each measurement series.

We applied a three-stage blank control covering the quality of vial preparation, helium purge efficiency, acid and silicate matrix purity with respect to CO2. The first stage was performed by analyzing empty vials with a standard portion of acid at the beginning and end of each measurement series. The second step (acid purity test) was performed by measuring empty vials with different amounts (0.2–1 mL) of acid. Third step was analyzing samples (1 to 5 mg) of silicate matrix (quartz) with appropriate amount of acid added. No chromatographic peaks of CO2 were observed at any stage.

KH-2, Ko, and MSA-8 carbonates were tested for homogeneity with respect to carbon and oxygen isotopic composition in a special calibration series, where ten sample weighs of 250 μg were analyzed (Table 1). With respect to carbon isotopic composition, all three carbonates are homogeneous within the range of 0.04–0.05‰ (1σ); with respect to oxygen isotopic composition, their homogeneity is somewhat lower, about 0.1‰ (1σ). Other measurement series revealed lower homogeneity in oxygen-isotope composition of MSA-8 calcite and KH-2 limestone and in carbon of MCA-8 calcite; however, these variations were rather random and had the order of 0.0n‰. It should be noted that the appearance of these carbonates is consistent with the difference in homogeneity of their oxygen- and carbon-isotopic compositions. MSA-8 is characterized by the largest grain size (Fig. 1a), while the heterogeneity of KH-2 limestone could be related to both the presence of impurities and the irregular grain size (Fig. 1b). Ko calcite (Fig. 1c), which turned out to be the most homogeneous in terms of isotopic parameters, is characterized by the uniform grain sizes, significantly smaller than the grains of MSA-8.

RESULTS

Carbonate Content in Silicate–Carbonate Mixtures Estimated by Chromatographic Peak Area

To estimate the carbonate content in the mixture, the area of one of the chromatographic peaks of the sample was used. We chose the fourth peak of the chromatogram corresponding to the first pulse of the sample coming from the vial as a reference. In contrast to the calibration based on the ion current intensity generated by mass 44 (Zha et al., 2017), we used the integrated peak area (Area All in the Isodat 3.0 software). Calibration of the correspondence of peak areas to the determined amount of CO2 in the analyzed gas was performed by analyzing different sample weights of pure carbonates of KH-2, Ko, and MCA-8. The smallest sample of pure carbonates was ≈50 μg, which is the technical limit for manual weighing and loading of the sample into a vial. Thus, the lower limit of the calibration lines that were used to calculate carbonate content was 0.5 µm CO2 (Table 2, Figs. 2a–2c).

Area of the fourth chromatographic sample peak (S, Vs) and expected amount of analyzed gas CO2(0), μmol, for a mixture based on (a) KH-2, (b) Ko, and (c) MSA-8. Trend lines plotted for the fourth peak of pure carbonate samples were used to calculate \({\text{CO}}_{2}^{*}\) in silicate–carbonate mixtures.

There was a regular difference between the expected amount of CO2 and the amount calculated from the peak area using the calibration line for all mixtures studied. In general, the analyte deficit ranged from 0.03 to 0.5 µm. We calculated the loss of analyzed gas as a percentage of the mass of the expected CO2 amount using the following formula:

where \({\text{C}}{{{\text{O}}}_{2}}{\kern 1pt} \left( 0 \right)~\) and \({\text{CO}}_{2}^{*}\) are the expected and real amounts of analyzed gas, respectively. The value of ΔCO2 grows with decreasing carbonate content in the mixtures (Table 2). Maximum gas deficit was observed in 1 and 2% mixtures (12–43.6%); the values of ΔCO2 in the mixtures with 2 to 10% carbonate content varied in smaller range (7–28%, Fig. 3), while CO2 discrepancy in silicate–carbonate mixtures with higher carbonate contents (25 and 50%), as was shown by preliminary tests, were insignificant.

Losses of analyzed gaseous CO2 as a function of carbonate content in silicate–carbonate mixtures: (a) absolute and (b) relative. Relative losses were calculated using Eq. (2).

Oxygen and Carbon Isotopic Composition of Silicate–Carbonate Mixtures

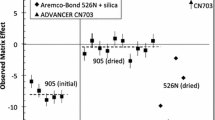

As expected, the values of δ13C and δ18O become distorted as the amount of CO2 decreases. A lighter isotopic composition of carbon was observed for mixtures prepared using KH-2 and Ko carbonates, while the mixtures based on MSA-8 displayed heavier carbon compositions. Deviations in oxygen-isotopic composition for all mixtures are directed one way, towards a decrease of δ18O values, reaching 3.6‰ (Table 2). Small deviations in the isotopic composition (up to ≈0.7‰) were also observed for small samples (≈50 μg) of pure carbonates. The magnitude of deviations in the isotopic composition of a sample relative to its original composition can be expressed by analogy with the isotopic fractionation factor: α: 103Lnα(C–C0) (≈δ13СMEAS– δ13СINI) and 103Lnα(О–О0) (≈δ18ОMEAS – δ18ОINI), where С, О and С0, О0 are the carbon- and oxygen-isotopic compositions of the carbonate in the mixture and of the original pure carbonate, respectively (Table 2) and indices MEAS and INI refer to measured and initial parameters, respectively. The values of 103Lnα(C–C0) and 103Lnα(О–О0) relative to the amount of gas measured \(\left( {{\text{CO}}_{2}^{*}} \right)\) are given in Fig. 4. Apparently, the experimental points obtained for mixtures prepared from the same carbonate form common trends, no matter whether the \({\text{CO}}_{2}^{*}\) value is lowered by decreasing the sample or by decreasing the carbonate concentration in the mixture.

Analysis of distorted isotopic parameters shows that, in the region of low \({\text{CO}}_{2}^{*}\) values, they are influenced by the CO2 source common for all mixtures, with an approximately constant isotopic composition of carbon and oxygen. The δ13C values in this source (blank) are significantly higher than the values in MSA-8 (–31.30‰) and lower than those in KH-2 (+2.0‰). Since the minimum carbon isotopic shifts in the low \({\text{CO}}_{2}^{*}\) region are observed for Ko-based mixtures, it can be concluded that the value of δ13C blank is close to δ13C(Ko) = –8.5‰. As for the oxygen-isotopic composition, with an isotopic shift revealed in all mixtures directed towards decreasing values of 103Lnα(О–О0), but manifested to different degrees, it can be assumed that the δ18O value of the total blank component is close to the δ18O values of the MSA-8 and Ko carbonates (19.48 and 16.50‰), but differs significantly from the oxygen isotopic composition of the KH-2 carbonate (27.73‰) (Fig. 4b).

The data obtained can be compared with experiments of Zha et al. (2010), for which, instead of \({\text{CO}}_{2}^{*}\) values, we use conversion to the absolute amount of CaCO3 (mg) contained in the sample. This is necessary because the cited work does not provide data on the areas of the chromatographic peaks, and the approximate calibration of the amount of gas was carried out by the intensity of the ion current of the mass 44. Nevertheless, the deviations obtained for the δ13C and δ18O as a function of the absolute amount of carbonate in the vial are similar in magnitude (Figs. 5a, 5b). Zha et al. (2010) only reported one-way deviation of the measured values from the true ones, because they used the same carbonate with constant isotopic parameters (δ13C = +1.61‰ and δ18O = +18.96‰) in the experiment. The values of δ13C in the KH-2 carbonate and δ18O in the Ko carbonate are close to the composition of this carbonate. The deviations given by (Zha et al., 2010) and shown in Fig. 5 point in the same direction and are close to the deviations obtained for these mixtures. The carbonates with other isotopic parameters may show more or less strong deviations, or even change sign, depending on the isotopic parameters of the blank. As the amount of gas analyzed increases, the role of the blank gradually levels off from the strong influence at \({\text{CO}}_{2}^{*}\) < 0.5 µm to almost complete absence at \({\text{CO}}_{2}^{*}\) < 1.5 μmol.

Deviation of (a) δ13C and (b) δ18O measured in silicate–carbonate mixtures from the true values depending on the absolute content of CaCO3 in the silicate–carbonate mixture. Data from the present work and experimental results from (Zha et al., 2010) are presented. Vertical dashed line is amount of CaCO3 (70 µg) recommended by Zha et al. (2010) as a threshold amount for isotopic analysis of silicate–carbonate mixtures.

DISCUSSION

Taking into Account Nonlinearity Related to the Amount of Analyzed Gas

This parameter can be minimized using mass-spectrometer ion-source settings and estimated by measuring portions of the same CO2 gas, differing in peak area. Test measurements were performed in the course of the prolonged experiment when isotopic ratios were measured in 43 portions of gas from the same vial filled with a 0.3% mixture of He with CO2. As the amount of CO2 in the vial was gradually decreased, the sample peaks had an increasingly smaller area and reach background levels at the end of the test. The results of such a test for δ13C values are shown in Fig. 6 in comparison with the data obtained by measuring silicate–carbonate mixtures prepared on the basis of KH-2 and MSA-8. It can be seen that the nonlinearity effect with the used instrument settings leads to a slight overestimation of the measured values of δ13C by 0.2–0.4‰ in the region of low peak areas and that this effect is small compared to the variations obtained when analyzing silicate–carbonate mixtures. Similar results were obtained for δ18O values, except that their overestimation was slightly stronger, up to 0.6–0.7‰ in the region of extremely low peak areas. The effect of instrumental nonlinearity is manifested uniformly for the values δ13C and δ18O and does not depend on the isotopic parameters of the measured gas, which allows it to be taken into account. In our case, the effect of nonlinearity is manifested in the region of peak areas of the first Vs and the corresponding correction averages 0.2–0.4‰ for all carbonate mixtures, which is extremely small compared to the effects caused by other factors.

Blank Effect

This factor is clearly manifested at decreasing absolute amount of analyzed gas, CO2(*), when differences in sign and absolute value of the parameters 103Lnα(C–C0) and 103Lnα(О–О0) begin to show (Table 2, Fig. 4). The data in Fig. 4 suggest that the effect of the blank on δ13C and δ18O is evident at \({\text{CO}}_{2}^{*}\) < 1.0 μmol and at \({\text{CO}}_{2}^{*}\) < 2 m, respectively, which corresponds to 100 and 200 μg of pure carbonate. In the case of carbon, our estimates are close to the threshold value of 70 μg established by (Zha et al., 2010). In the case of oxygen, we believe that the threshold amount should be increased to 200 μg if the standard GasBenchII option is used. The fact that the oxygen-isotope system appears to be more sensitive to the blank effect than the carbon-isotope system has been attributed to the presence of trace amounts of water (Zha et al., 2010), including that condensed on the vial walls above the acid surface (Wachter and Hayes, 1985). Otherwise, carbon-dioxide particles adsorbed by the vial walls and sample surface are responsible for the blank effect. Considering that the influence of adsorption on the vial walls can be neglected, since it is a constant value for all experiments, it can be assumed that the blank contribution must be proportional to the mass of the solid sample in the vial:

where γ(b) is a constant coefficient equal to the content of adsorbed CO2 gas in 1 mg of the mixture and M is the mass of the sample.

Despite purging with high-purity helium and a high-quality preparation of vials and starting materials (Paul and Skrzypek, 2006; Nelson, 2000) CO2 blank is extremely difficult to remove from the reaction space. We estimate that the blank contribution may be about 1–3% of the total amount of gas analyzed, corresponding to a value of γ(b) ≈ 0.005 μmol CO2. At ultralow (less than 1%) carbonate contents, the measured isotopic parameters of the sample can be significantly distorted because increasing the mass of the suspension, according to relation (3), raises the blank contribution.

Analyzing carbonate–silicate mixtures different in isotopic parameters, we evaluated the isotopic parameters of the blank, which turned out to be close to the composition of Ko carbonate, deviating by about 0.5‰ in both carbon and oxygen towards lighter isotopic compositions (Fig. 4). To a first approximation, the δ13C and δ18O values of the blank are about –9 ± 1 and +16 ± 1‰, respectively. The carbon-isotopic composition of the blank is close to the δ13C values of atmospheric carbon dioxide (Gruber et al., 1999; NOAA ESRL GMD). The magnitude of δ18O in blank CO2 is probably controlled to some extent by equilibrium with atmospheric moisture, but this cannot be established precisely because moisture composition can vary significantly in the ground-level atmosphere and is only partially determined by the mean isotopic composition of precipitation and air temperature (Jacob and Sonntag, 1991, Bastrikov et al., 2014).

Effect of Silicate Matrix

Laboratory standard quartz (Polaris) prepared from a large fragment of vein quartz from the Zhelannoe deposit (Polar Urals) was used as a matrix in our experiments. The quartz has a homogeneous oxygen-isotope composition (δ18O = 13.05 ± 0.05‰) and a minimal number of inclusions. Figure 1d shows a photo of Polaris quartz grinded in an agate mortar, taken during preparation of the mixtures, i.e. exactly as the matrix present in the analytical space. Very few particles exceed the size of 20 µm, predominant size being 5–10 µm, which, apparently, is responsible for the matrix effect, clearly manifested in losses of the analyzed gas (Table 2) in the most carbonate-poor mixtures.

In contrast to the blank effect, expressed as an additional, albeit very small, contribution of extraneous gas to the sample, the matrix effect is manifested in the opposite way, i.e., by partial retention of CO2 in the part of the vial that is occupied by the mixture of the sample with orthophosphoric acid. The total effect associated with the action of the blank and matrix can be expressed as a balance equation for the amount of \({\text{CO}}_{2}^{*}\) measured in the sample:

where CO2 (b) and CO2 (m) are the amount of CO2 added to the sample due to the blank and removed from the sample due to the matrix effect, respectively. By analogy with Eq. (3), the following should be true for the matrix effect:

where γ(m) is a constant coefficient equal to the amount of CO2 removed from the reaction space when a sample has a mass of 1 mg. The balance equation, taking into account the isotopic shift produced by both entry of the blank into the sample and the loss of the sample material due to the matrix effect, can be written as follows:

where the values δ0, δb, δ*, and δm are the carbon- or oxygen-isotopic composition of CO2 of the initial carbonate, blank, analyzed gas, and gas lost due to matrix effect, respectively. The combination of Eqs. (3)–(5) leads to the following important relation:

where γ(0) is the amount of CO2 that theoretically should be extracted from 1 mg of the sample. Relationship (7) allows parameter γ(m) to be found in the case in which parameter γ(b) is known or assumed. Assuming that γ(b) is approximately constant for all experimental mixtures and is 0.005 µm CO2 and using the blank isotopic parameters given above (see Section 3.2), we calculated the isotopic parameters of the gas removed due to the matrix effect using Eq. (6). The nonlinearity effect was taken into account in the calculations according to the calibration carried out in the prolonged testing experiment.

The resulting δ13С(m) and δ18О(m) estimates in the CO2 gas lost by the sample due to matrix effects are higher than the δ13С(0) and δ18О(0) values in the original carbonates. The degree of this increase is almost equal for the carbon- and oxygen-isotopic compositions, indicating kinetic fractionation of carbon and oxygen isotopes in the process of CO2 capture by the matrix (Fig. 7).

It is important that the direction of isotopic shifts 103*Lnα(O(m)–O(0)) and 103Lnα(C(m)–C(0)) does not depend on isotopic parameters of the analyzed gas, i.e. the matrix effect, unlike the blank effect, is directed towards retention of CO2 molecules that are enriched in heavy 13C and 18O isotopes. This result can be explained in at least two ways. The first explanation was proposed by (Zha et al., 2010), who suggested that some of the CO2 molecules do not have time to diffuse through the layer of viscous orthophosphoric acid and do not get into the free space to be taken for measurements. Indeed, kinetic fractionation during diffusion of CO2 molecules through the acid layer can lead to enrichment of the gas remaining in the acid with CO2 molecules with heavier isotopic composition. However, it should be borne in mind that the elevated temperature in the reaction zone (70°C) significantly reduces the viscosity of the acid and that the reaction time (2 h) is quite sufficient for effective gas yield even from its maximum volume (0.2 mL) used in our experiments. The second option is partial adsorption of CO2 on the surface of solid particles wetted with orthophosphoric acid. This process can also lead to enrichment of adsorbed gas with heavy 13C and 18O isotopes.

To test the first option, we conducted an experiment with an additional batch of samples of pure KH-2 carbonate, which had different sample weights, from ≈100 to ≈250 μg in increments of about 50 μg. Three samples of each mass were prepared, a standard amount of orthophosphoric acid (0.05 mL) was added to two of them, and the maximum amount used in this work (0.2 mL) was added to the third. All other experimental parameters were identical to those we used for studying silicate–carbonate mixtures and performing peak area calibrations. The results of this experiment are shown in Fig. 8 as a dependence of the chromatographic peak area on the mass of the KH-2 carbonate sample. If the losses of the analyzed gas were due to diffusion in the acid, the experiments with a larger amount of acid would have produced weaker dependence than those obtained using a standard volume of acid (similar to the patterns shown in Figs. 2a–2c). However, it can be seen that, in the absence of the silicate matrix, we obtain the same amounts of analyzed gas from the same carbonate suspensions regardless of the volume of acid added. Consequently, the loss and distortion of isotopic parameters of the measured gas are neither related to the diffusion of CO2 in the acid nor to its amount, as was suggested by Zha et al. (2010), but precisely to the presence of silicate matrix particles. This effect does not depend on the composition of the analyzed carbonates and is always expressed in the underestimation of the measured values of δ13C and δ18O, since the adsorbed gas is enriched in heavy isotopes of carbon and oxygen (Fig. 7).

The influence of matrix particles surrounded by acid has been repeatedly discussed in studies of the selective dissolution of mixtures of carbonate minerals, primarily calcite and dolomite (Walters et al., 1972; Spotl and Wennemann, 2003; Rosenbaum and Sheppard, 1986; Liu et al., 2018; Du and Song, 2020; Sreenivasan et al., 2023). The matrix in these experiments was dolomite or another carbonate with a lower dissolution rate than calcite. For example, it has been suggested that some of the CO2 may form microscopic bubbles accumulating around the matrix particles in the viscous acid; therefore, microvibration of the autosampler platform could have prevented the effect (Sreenivasan et al., 2023). All of this work was carried out at reduced temperatures to allow dissolution of calcite without cross contamination by dolomite, where the acid is indeed viscous. Had the matrix effect been related to a bubble mechanism, however, there would need to be isotopic fractionation between the small and large CO2 bubbles released during the reaction of calcite with acid, with the heavy isotopes 13C and 18O being concentrated in the small bubbles, which, in our opinion, is unlikely.

The matrix effect that we observed, in principle, corresponds to the idea of adsorption, in which kinetic effects are directed toward decreasing both δ13C and δ18O in the gas leaving the acid-covered matrix zone. The same isotopic shifts have been repeatedly documented in selective carbonate dissolution for the first portions of CO2 produced by calcite dissolution when the matrix mass in the system was at its maximum (Walters et al., 1972; Liu et al., 2018; Du and Song, 2020; Al-Assam et al., 1990; Baudrand et al., 2012). This effect was independent of the isotopic composition of the calcite used to make the experimental mixtures. Taking into account that the matrix effect is accompanied by a significant absorption of the analyzed gas, we can conclude that the matrix–acid–gas interface plays a key role in the matrix effect. Further experiments, e.g., studying various matrix material, are required to investigate this interesting problem.

The Role of the Studied Effects in Distorting the Results of Analysis of Silicate–Carbonate Mixtures

The main sources of errors, as well as the values of isotopic shifts caused by the influence of each of the considered factors, are different. The smallest is the contribution of nonlinearity of instrument measurements in the region of small gas contents. It is constant for specific instrument settings and the specific state of the measuring system, and it is easy to calibrate and take into account.

The blank effect significantly distorts the isotopic parameters of the measured gas in the samples without affecting the accuracy of measured concentrations. It is most strongly manifested in the samples with low (1–5%) carbonate content, reaching the first ppm. In contrast, the matrix effect strongly affects measured carbonate contents in the mixture, with little effect on the results of isotopic determinations. Carbonate contents less than 10 and 5% are expected to be underestimated by 20 and 30–40%, respectively. The isotopic shift associated with the matrix effect is always directed towards the depletion of the analyzed gas in 13C and 18O isotopes, and the shift is not very significant due to the weak isotopic effect of adsorption. Sometimes, the matrix effect can be compensated by the blank effect if the latter works in the opposite direction. If the isotopic parameters (δ13C and δ18O) of the blank are significantly lower than those in the sample, the factors are added together and their mutual effect leads to a significantly lighter isotopic composition of the measured gas. Such a case is observed, e.g., for mixtures based on KH-2 (Figs. 4–7). Since this carbonate is close in isotopic composition to carbonates of marine sedimentary origin (Table 1), one can expect analytical errors to appeal when analyzing rocks containing carbonate material with sedimentary characteristics.

The importance of the effects can be shown by the example of calculated isotopic shifts accompanying the process of high-temperature decomposition of carbonate with typical sedimentary characteristics (Fig. 9). We calculated the shift of δ13С and δ18О values in the residual carbonate with KH-2 isotopic parameters (Table 1) as it decarbonizes at 600°C (Bottinga, 1986; Chacko and Deines, 2008). Along with the calculated curve, the values of δ13С* and δ18О* measured in the mixtures prepared with KH-2 are plotted in Fig. 9. The measured compositions almost exactly correspond to the calculated curve; i.e., these data can be erroneously interpreted as the result of high-temperature decomposition of sedimentary carbonate with CO2 removal, with a process depth of up to 60%. In fact, we are dealing with an artifact due to blank and silicate matrix effects.

Calculated line of isotopic parameter alteration of KH-2 carbonate during its decomposition with CO2 removal at 600°. The fractionation factors of carbon and oxygen isotopes in the CO2–CaCO3 system are taken from Bottinga (1968) and (Chacko and Deines, 2008). Numbers near the line are the fraction of remaining carbonate after partial decomposition (% of the initial amount). Dots are the measured carbon- and oxygen-isotopic compositions of samples of silicate–carbonate mixtures prepared on the basis of KH-2.

CONCLUSIONS

The results of experiments lead to the conclusion that the total error of isotopic analysis of carbonate-poor silicate rocks (up to 10 wt % in terms of CaCO3) is composed of three main factors: instrumental nonlinearity of measurements of small amounts of gas, the blank effect, and the silicate-matrix effect. Each of these effects can be accounted for, but only to a certain extent. Minimizing the blank effect can be done by reducing the volume of the vials (Breitenbach and Bernasconi, 2011) or by changing the heating conditions of the samples. However, matrix effects can only be accounted for if the exact mechanism of interaction between the matrix surface and CO2 is understood. Obviously, ignoring these effects can lead to significant distortion of the measured results and affect their interpretation. At the moment, silicate rocks with low carbonate content cannot be analyzed with the same accuracy as pure carbonates, at least by standard methods. The data-correction approach based on measuring variable portions of pure carbonate standards, as well as the use of very large sample weights, are not helpful because of the possible influence of matrix and blank. At carbonate contents of about 1–2%, deviation of δ13C and δ18O from the true values can reach the first ppm and the carbonate content obtained from the chromatographic peak area can be underestimated by up to 40%.

The analysis of silicate rocks with low carbonate content requires a special approach, such as mandatory assessment of the nonlinearity of instrumental measurements and measures to minimize the blank contribution—in addition to special requirements for clean utensils and reagents, sample baking prior to analysis is recommended; some other measures may also be taken. The matrix effect can be detected only if the carbonate content in the sample is known in advance, therefore one should keep in mind the possible manifestation of this effect and, hence, underestimated values of δ13C and δ18O in the case of, e.g., deficiency of the analyzed gas.

REFERENCES

I. S. Al-Aasm, B. E. Taylor, and B. South, “Stable isotope analysis of multiple carbonate samples using selective acid extraction,” Chem. Geol. (Isot. Geosci. Sect.) 80, 119–125 (1990).

J. C. Alt and W. C. III. Shanks, “Stable isotope compositions of serpentinite seamounts in the.Mariana forearc: Serpentinization processes, fluid sources and sulfur metasomatism,” Earth Planet. Sci. Lett. 242, 272–285 (2006).

V. Bastrikov, H. Steen-Larsen, V. Masson-Delmotte, K. Gribanov, O. Cattani, J. Jouzel, and V. Zakharov, “Continuous measurements of atmospheric water vapour isotopes in western Siberia (Kourovka),” Atmosph. Meas. Techn. 7 (6), 1763–1776 (2014). 5194/amt-7-1763–2014

M. Baudrand, G. Aloisi, C. Lécuyer, F. Martineau, F. Fourel, G. Escarguel, M.-M. Blanc-Valleron, J.‑M. Rouchy, and V. Grossi, “Semi-automatic determination of the carbon and oxygen stable isotope compositions of calcite and dolomite in natural mixtures,” Appl. Geochem. 27, 257–265 (2012).

M. Bottinga, Calculation of fractionation factors for carbon and oxygen isotopic exchange in the system calcite-carbon dioxide-water. J. Phys. Chem. 72, 800–808 (1968).

W. Brand, “High precision isotope ratio monitoring techniques in mass spectrometry,” J. Mass Spectrom. 31 (3), 225–35 (1996).

W. A. Brand, “Mass spectrometer hardware for analyzing stable isotope ratios,” In Handbook of Stable Isotope. Analytical Techniques, Ed. by P. A. de Groot (Elsevier, Amsterdam, 2004), pp. 835–858.

S. F. M. Breitenbach and S. M. Bernasconi, “Carbon and oxygen isotope analysis of small carbonate samples (20 to 100 μg) with a Gas–Bench II preparation device,” Rapid Commun. Mass Spectrom. 25 (13), 1910-1914 (2011).

J. Burman, O. Gustafsson, M. Segl, and B. Schmitz, “A simplified method of preparing phosphoric acid for stable isotope analyses of carbonates,” Rapid Commun. Mass Spectrom. 19 (21), 3086–3088 (2005).

T. Chacko and P. Deines, “Theoretical calculation of oxygen isotope fractionation factors in carbonate systems,” Geochim. Cosmoch. Acta. 72 (15), 3642–3660 (2008).

Y. Du and H. Song, “Refined protocol for δ13C analysis of calcite and dolomite in carbonate mixture samples. Rapid Commun. Mass Spectrom. 34 (10), (2020). https://doi.org/10.1002/rcm.8743

E. O. Dubinina, A. A. Nosova, and A. S. Avdeenko, and L. Ya. Aranovich, “Isotopic (Sr, Nd, O) systematics of the high Sr–Ba Late Miocene granitoid intrusions from the Caucasian Mineral Waters region,” Petrology 18(3), 211–238 (2010).

E. O. Dubinina, L. G. Filimonova, and S. A. Kossova, “Isotope (δ34S, δ13C, δ18O) compositions of disseminated sulfide mineralization in igneous rocks of the Dukat ore deposit (Northeastern Russia),” Geol. Ore Deposits 61 (1), 38–49 (2019).

ESRL Global Monitoring Division (NOAA ESRL GMD). https://www.esrl.noaa.gov/gmd/

J. Fiebig, B. Schöne, and W. Oschmann, “High-precision oxygen and carbon isotope analysis of very small (10–30 µg) amounts of carbonates using continuous flow isotope ratio mass spectrometry,” Rapid Commun. Mass Spectrom. 19 (16), 2355–2358 (2005).

Finnigan Gasbench II Operating Manual (Thermo Electron Corporation, Bremen, 2004).

E. M. Galimov, “Isotope fractionation related to kimberlite magmatism and diamond formation,” Geochim. Cosmochim. Acta. 55, 1697–1708 (1991).

A. Giuliani, D. Phillips, V. S. Kamenetsky, M. L. Fiorentini, J. Farquhar, and M. A. Kendrick, “Stable isotope (C, O, S) compositions of volatile-rich minerals in kimberlites: A review,” Chem. Geol. 374–375, 61–83 (2014).

N. Gruber, C. D. Keeling, R. B. Bacastow, P. R. Guenther, T. J. Lueker, M. Wahlen, H. A.J. Meijer, W. G. Mook, and T. F. Stocker, “Spatiotemporal patterns of carbon-13 in the global surface oceans and the oceanic Suess effect,” Global Biogeochem. Cycles 13 (2), 307–335 (1999).

H. Jacob and C. Sonntag, “An 8-year record of the seasonal variation of δ2H and δ18O in atmospheric water vapour and precipitation at Heidelberg, Germany,” Tellus B 43, 291–300 (1991).

X. Liu, W. Deng, and G. Wei, “Carbon and oxygen isotopic analyses of calcite in calcite–dolomite mixtures: Optimization of selective acid extraction,” Rapid Commun Mass Spectrom. 33 (5), 411–418 (2018). https://doi.org/10.1002/rcm.8365

J. M. McCrea, “On the isotopic chemistry of carbonates and a paleotemperature scale,” J. Chem. Phys. 18, 849–857 (1950).

S. T. Nelson, “Sample vial influences on the accuracy and precision of carbon and oxygen isotope ratio analysis in continuous flow mass spectrometric applications,” Rapid Commun. Mass Spectrom. 14 (4), 293–297 (2000).

D. Paul and G. Skrzypek, “Flushing time and storage effects on the accuracy and precision of carbon and oxygen isotope ratios of sample using the Gasbench II technique,” Rapid Commun. Mass Spectrom. 20, 2033–2040 (2006).

D. Paul and G. Skrzypek, “Assessment of carbonate–phosphoric acid analytical technique performed using GasBench II in continuous flow isotope ratio mass spectrometry,” Int. J. Mass Spectrom. 262, 180–186 (2007).

D. Paul, G. Skrzypek, and I. Fórizs, “Normalization of measured stable isotopic compositions to isotope reference scales – a review,” Rapid Commun. Mass Spectrom. 21 (18), 3006–3014 (2007).

K. Révész and J. Landwehr, “δ13C and δ18O isotopic composition of CaCO3 measured by continuous flow isotope ratio mass spectrometry: Statistical evaluation and verification by application to Devils Hole core DH-11 calcite,” Rapid Commun Mass Spectrom. 16, 1012–2114 (2002).

J. M. Rosenbaum and S. M. Sheppard, “An isotopic study of siderites, dolomites and ankerites at high temperatures,” Geochim. Cosmoch. Acta. 50, 1147–1150 (1986).

G. Skrzypek and D. Paul, “Delta13C analyses of calcium carbonate: Comparison between the GasBench and elemental analyzer techniques,” Rapid Commun. Mass Spectrom. 20, 2915–20 (2006).

C. Spötl and T. Vennemann, “Continuous-flow isotope ratio mass spectrometric analysis of carbonate minerals,” Rapid Commun. Mass Spectrom. 17, 1004–1006 (2003).

S. Sreenivasan, M. K. Bera, and A. Samanta, “A simple but improved protocol for measuring carbon and oxygen isotope ratios of calcite in calcite–dolomite mixtures,” Appl. Geochem. 150, 105600 (2023). https://doi.org/10.1016/j.apgeochem.2023.105600

T. Velivetskaya, A. Ignatiev, and S. Gorbarenko, “Carbon and oxygen isotope microanalysis of carbonate,” Rapid Commun Mass Spectrom. 23, 2391–2397 (2009).

E. A. Wachter and J. M. Hayes, “Exchange of oxygen isotopes in carbon dioxide-phosphoric acid systems. Isot Geosci. 52, 365–374 (1985).

L. J. Walters, G. E. Claypool, and P. W. Choquette, “Reaction rates and δ18O variation for the carbonate–phosphoric acid preparation method,” Geochim. Cosmochim. Acta 36, 129–140 (1972).

R. A. Werner and W. A. Brand, “Referencing strategies and techniques in stable isotope ratio analysis,” Rapid Commun Mass Spectrom. 15 (7), 501–519 (2001).

D. Yong and H. Song, “Refined protocol for the δ13C analysis of calcite and dolomite in carbonate mixture samples,” Rapid Commun Mass Spectrom. 34 (10), e8743 (2020). https://doi.org/10.1002/rcm.8743

X.-P. Zha, Y. -Y. Zhao, and Y.-F. Zheng, “An online method combining a Gasbench-II with continuous flow isotope ratio mass spectrometry to determine the content and isotopic compositions of minor amount of carbonate in silicate rocks,” Rapid Commun. Mass Spectrom. 24, 2217–2226 (2010).

X.-P. Zha, B. Gong, Y.-F. Zheng, and Y.-X. Chen, “Precise carbon isotopic ratio analyses of micro amounts of carbonate and non-carbonate in basalt using continuous—flow isotope ratio mass spectrometry,” Rapid Commun. Mass Spectrom. 32, 48–56 (2017).

Z.-F. Zhao, Y. -F. Zheng, C.-S. Wei, and B. Gong, “Carbon concentration and isotope composition of granites from Southeast China,” Phys. Chem. Earth. Parts A/B/C 26, 821–833 (2001).

Y.-F. Zheng, B. Gong, Y. Li, Z. Wang, and B. Fu, “Carbon concentrations and isotopic ratios of eclogites from the Dabie and Sulu terranes in China,” Chem. Geol. 168, 291–305 (2000).

Y.-F. Zheng, B. Gong, Z.-F. Zhao, B. Fu, and Y.-L. Li, “Two types of gneisses associated with eclogite at Shuanghe in the Dabie terrane: Carbon isotope, zircon U-Pb dating and oxygen isotope,” Lithos 70, 321–343 (2003).

ACKNOWLEDGMENTS

The authors are grateful to the scientific editor V.S. Sevastyanov, B.G. Pokrovsky, an anonymous reviewer, and V.B. Polyakov for constructive comments that allowed them to improve this work.

Funding

This work was carried out within the framework of a state order of the Institute of Geology of Ore Deposits, Petrography, Mineralogy and Geochemistry, Russian Academy of Sciences, topic no. FMMN-2021-009.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

The authors declare that they have no conflicts of interest.

Additional information

Translated by M. Hannibal

Rights and permissions

Open Access. This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license, and indicate if changes were made. The images or other third party material in this article are included in the article’s Creative Commons license, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons license and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this license, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Dubinina, E.O., Chizhova, Y.N. & Kossova, S.A. Isotopic (δ13C, δ18O) Analysis of Small Amounts of Carbonate in Silicate Rocks by the Continuous Flow Isotope Ratio Mass Spectrometry Method. Geochem. Int. 61, 1164–1176 (2023). https://doi.org/10.1134/S0016702923110034

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S0016702923110034