Abstract

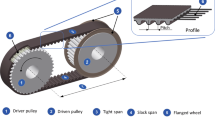

In this study, a novel failure diagnostic system for timing belts was developed in order to prevent a catastrophic belt failure. These failures may occur before running out the nominal belt life and lead to an extensive engine damage, thereby resulting costly repairs. Timing belt failures are generally resulted from three reasons, that is, lack of a tooth, fiber separation on belt sides, and teeth splitting. Three optical sensors with laser beam whose diameter is 0.6 mm was located on suitable positions and it is used to produce error signal resulted from disturbance of laser beam flows due to failure. The error signal is processed by the processor, which is independent from the electronic control unit (ECU) to alert the driver or ECU, directly. Experimental apparatus which consists of two camshaft pulleys and an idler pulley with belt tensioner has been set up to simulate real engine conditions. Experimental results show that the optical monitoring technique is reliable to determine timing belt failure types simultaneously in the range of 500–7000 rpm engine speed and it is also easier, low cost and more applicable than other methods such as vibration monitoring.

Similar content being viewed by others

References

Iizuka, H., Watanabe, K., and Mashimo, S., “Observations of Fatigue Failure in Synchronous Belts,” Fatigue and Fracture of Engineering Materials and Structures 17-7:783–790 (1994).

Dalgarno, K.W., Day, A.J., Childs, T.H.C., and Moore, R.B., Stiffness Loss of Synchronous Belts, Elsevier, Composites Part B: Engineering 9:217–222 (1998).

Mack, J.E., Belt Flaw Detector, Patent 5994712, Patent and Trademark Office, United States (1999).

Ahmed, A.A.A., Method and Apparatus for Detecting Timing Belt Damage Using Inductive Link Coupling, Patent 6532810, Patent and Trademark Office, United States (2001).

Ahmed, A.A.A., Method and Apparatus for Detecting Timing Belt Damage Using Link Coupled Feedback, Patent 6523400, Patent and Trademark Office, United States (2003).

Blander, R.S., Wenzel, K.J., and Piska, V.G., “Method of detecting timing apparatus malfunction in an engine”, Patent 5463898, Patent and Trademark Office, United States (1995).

Gates Corp., Industrial Synchronous Belts Design Manual, E2/20099 (2007).

Childs, T.H.C., Dalgarno, K.W., Day, A.J., and Moore, R.B., “Automative Timing Belt Life Laws and a User Design Guide,” Proceedings Institution of Mechanical Engineers Part D 212:409–419 (1998).

Basso, R., “Detection of Reduced Tooth Stiffness in Synchronous Belts by Means of Pulley Vibration Monitoring,” Proceedings of IMechE Part D, Journal of Automobile Engineering 220:947–957 (2006).

Ergün, R.E., “Real Time Failure Detection on the Timing Belt Using Internal Combustion Engines,” MSc Thesis (2009).

Erickson, W.D., Belt Selection And Application for Engineers, Marcel Dekker (1987).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Ucar, M., Ergun, R.E. & Cengiz, A. A novel failure diagnosis system design for automotive timing belts. Exp Tech 38, 48–53 (2014). https://doi.org/10.1111/j.1747-1567.2012.00842.x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1111/j.1747-1567.2012.00842.x