Abstract

The performances of two identical biofilters, filled with a new composite packing material (named CM-5) embedded with functional microorganisms or sterilized CM-5 without microorganisms, were investigated for H2S treatment. Running parameters in terms of microbial counts, pressure drops, and inlet and outlet H2S concentrations were measured. The results show that the microbial count of the CM-5 was approximately ×105 CFU/g before being filled into the biofilter, while that of the sterilized CM-5 was negligible. The functional microorganisms embedded in CM-5 adapted to the environment containing H2S quickly. In most cases, pressure drops of the CM-5 biofilter were slightly higher than those of the sterilized CM-5 biofilter when the gas flow rate was 0.6–2.5 m3/h. The maximum elimination capacity (EC) of the CM-5 biofilter in treating H2S could reach up to 65 g/(m3·h) when the loading rate (LR) was approximately 80 g/(m3·h). If the LR was much higher, the measured EC showed a slight downward trend. The experimental ECs of biofilters were fitted by two typical dynamic models: the Michaelis-Menten model and the Haldane model. Compared with the Michaelis-Menten model, the Haldane model fit the experimental ECs better for the two biofilters because of the presence of the substrate inhibition behaviour.

Similar content being viewed by others

Explore related subjects

Find the latest articles, discoveries, and news in related topics.Introduction

It is widely known that malodorous hydrogen sulfide (H2S) emissions have potential extreme toxicity with respect to human health and aggressive corrosion with respect to buildings1,2. Considerable amounts of H2S are emitted from wastewater treatment and industrial activities, such as paper manufacturing and rubber processing3. Except for traditional physico-chemical technologies, H2S emissions can also be removed using biotechnologies, such as biofiltration. Biofiltration is considered to be good for the environment because it consumes lower energy and generates little undesirable byproducts during treatment. Moreover, other intermediate products, such as HS− and S2−, could be used as energy sources by microorganisms4.

Microorganisms play a major role in the biofiltration system because the purification efficiency mainly depends on the microbial activity. However, the core of the biofiltration system might be the packing materials. A suitable packing material could provide an ideal microenvironment for microorganism growth, such as abundant nutrients and uniform distributions of water and air5,6,7. According to previous studies, the optimal packing materials should have specific physicochemical properties, such as suitable particle size, large surface area, high porosity, good mechanical resistance and moisture retention. Moreover, a high buffer capacity to avoid large pH fluctuations and abundant nutrient sources are also necessary4,8,9,10,11. Some studies have also shown that optimal packing material should contain microorganisms to shorten the period of biofilm formation at start-up12,13,14.

A plethora of research on different types of packing materials (organic, inorganic and synthetic materials) has been conducted for biofilters15. Organic materials, such as waste compost, sugarcane bagasse, coconut fibre and wood bark, have advantages in terms of nutrient sources and native microorganisms, while they tend to compact after running a course of time, which will result in increasing pressure drops and cause inhomogeneous air flow distributions16. Inorganic materials, such as lava rock, metal oxides, ceramsite and pall ring, can also be used. However, these inorganic materials must be inoculated with microorganisms with a period of 7–14 days. Moreover, inorganic packing materials cannot provide nutrients for microorganisms. To overcome the inherent problems of both organic and inorganic materials, such as bed compaction or lack of nutrients, synthetic packing materials have attracted researchers’ attention. Development of new composite packing materials has become a new research direction. Over the last few years, the formulation and performance of several synthetic packing materials have been reported. For example, Chan, W. et al.17 synthesized a composite bead containing poly/peat/KNO3, which could remove 98% of volatile organic compounds (VOCs) in a biofilter. Dumont, E. et al.15 developed a synthetic material (named UP20); this material not only supplies nutrients but also has good pH buffering capacity. A composite material for biofiltration was prepared by JiaDe, W. et al.18; this novel media has a function of slow nutrient release. However, only few papers have evaluated the performance of packing material embedded functional microorganisms in a biofilter12,19.

A recent study highlighted that a composite packing material (called CM-5, representing a composite material embedding more than ×105 CFU/g functional microorganisms) is a good packing material in terms of embedding functional microorganisms, providing nutrients and buffering pH fluctuation12. The aim of this study is to further investigate the contribution of functional microorganisms embedded in the materials. A crucial comparison was carried out using two identical biofilters filled with original CM-5 (i.e., the materials embedded with microorganisms) and sterilized CM-5 (i.e., the material without microorganisms), respectively. During the manufacturing process, the possibility of shutdown due to mechanical failures should be considered. Therefore, one week of interruption was set in the test to investigate the response of the composite packing materials.

Results and Discussion

Microbial counts

Figure 1 shows the microbial count behaviour of CM-5 and sterilized CM-5 biofilters along with the operation. There were approximately ×105 CFU/g of CM-5 at the beginning of the experiment. After running 10 days, the quantity of microorganisms on CM-5 reached ×106 CFU/g, indicating that the functional microbial communities adapted to the environment containing H2S and propagated rapidly. In contrast, the microbial quantity on the sterilized CM-5 was small and the breed rate was slow. Evidently, the quantity of microorganisms on CM-5 was much higher than that of the sterilized CM-5 throughout the experiments. One reason was that there were large amounts of functional microorganisms on CM-5, while those of sterilized CM-5 were mainly from waste gas and spraying water. Another speculation might be that the bioavailability of nutrients contained in sterilized CM-5 decreased through the sterilization process. Because of mechanical failure or other incidents, temporary interruption of the bio-treatment system is unavoidable. To investigate the impact of interruption on the microbial behaviour in a biofilter, a seven-day interruption was set at the 40th day. Figure 1 shows that both biofilters were impacted by the interruption and that their microbial quantities experienced some decrease. This result was mainly attributed to the moisture of the packing bed being too low, leading to some microorganisms being dormant or dying during the interruption. However, after resumption, quantities of microorganisms on both CM-5 and sterilized CM-5 recovered rapidly to ×106 and ×105 CFU/g of material, respectively. The short recovery period might be due to the rapid recuperation of enzymatic activity and microorganism metabolism from dormancy11. This phenomenon was consistent with that obtained in some studies. For example, Moe, W. et al.20 observed that a five-day period was needed to recover after a two-day shutdown; Maestre, J. et al.11 reported that the recovery period was 3–7 days after a five-day shutdown. This result indicated that both CM-5 and sterilized CM-5 could shorten the start-up period and limit the negative effects due to shutdowns and loading rate fluctuations, which might be mainly attributed to their nutrient slow-release capacity.

Overall, CM-5 contained abundant microorganisms, which proliferated rapidly after introducing a mixture gas including H2S. Microbial counts of both CM-5 and sterilized CM-5 decreased during the interruption period, but they recovered rapidly after re-starting the system.

Pressure drops

The pressure drops are closely related to the operating cost of the biofilter system, which could be impacted by many factors, such as the water content, airflow velocity, packing material size and material shape. In this section, only the superficial gas velocity and microorganisms on the materials were considered. Figure 2 shows the relationship between pressure drop values and superficial gas velocity after the two biofilters were run for 30 days. The results reveal that the term ΔP/(L·V) (ΔP is the pressure drop along the packing material bed length (Pa); L is the height of the packing material layer (m); V is the superficial air velocity (m·s−1)) was proportional to the gas velocity, indicating that pressure drop values fit the Ergun equation very well. The linear correlations were 0.974 and 0.963 for the CM-5 biofilter and sterilized CM-5 biofilter, respectively. Different amounts of increase in pressure drops were observed for the two packing materials. Specially, the β constant values, representing the energy losses, calculated from the fitted equations were 6477.0 and 5146.5 Pa/(s2·m3) for CM-5 and sterilized CM-5, respectively. Clearly, the β constant value (β (Pa·s2/m3) is the regression parameter) of CM-5 was higher than that of sterilized CM-5, which was attributed to the biomass on CM-5 being higher than that on sterilized CM-5, as shown in Fig. 1. More biomass on the material surface might result in the void space among the CM-5 becoming a little smaller, increasing the pressure.

The β value of CM-5 was similar to that of the synthetic nutritional material (UP20) (8,440 Pa/(s2·m3))15 and significantly lower compared with those obtained for polyurethane foam, sugarcane bagasse and coconut fibre: 55,813, 46,708, 114,775 Pa/(s2·m3), respectively1. It should be noted that CM-5 and UP20 have a similar shape. The comparison also illustrated that the material had significant impacts on the pressure drops. According to the experimental measurements, the biggest pressure drop value was 6.3 Pa/m for a gas velocity of approximately 0.028 m/s (i.e., 100 m/h) for CM-5 and sterilized CM-5. For similar gas velocity, pressure drop values reported in the literature were approximately 20 Pa/m for expanded schist15 and 40 Pa/m for peat4, which may be because the size of CM-5 was larger than that of UP20 and peat, which would generate larger gaps and lead to smaller air pressure.

Overall, pressure drop of the biofiltration increased as the gas velocity increased, and the pressure values suited the Ergun equation quite well. In most cases, the pressure drop values of CM-5 were slightly higher than those of sterilized CM-5.

Loading rate and elimination capacity

Loading rate (LR) of the pollutant always fluctuates during the actual operation, which may impact the elimination capacity (EC). In this study, the relationship between LR and EC of H2S was investigated; the LR was controlled by changing the inlet H2S concentration and keeping the inlet gas flow rate constant. Figure 3 shows the variation trend of EC with increasing LC for the CM-5 and sterilized CM-5 biofilters. Clearly, the response of the dependent variable (EC) to the variable (LR) was similar for CM-5 and sterilized CM-5 biofilters. ECs of both CM-5 and sterilized CM-5 increased to a maximum and then decreased slightly as LRs increased. Take CM-5 for example; the removal efficiency (RE) of the CM-5 biofilter was approximately 100% when LR was lower than 49.5 g/(m3·h), then RE gradually decreased. As LR increased, EC increased first and reached a peak: approximately 60 g/(m3·h). When the LR was higher than 80 g/(m3·h), EC was found to drop noticeably. Additionally, the EC of sterilized CM-5 reached the maximum value (10.2 g/(m3/h)) when LR was approximately 35 g/(m3/h). Kim, J. et al.21 observed similar result in treating H2S by using biomedia encapsulated by polyvinyl alcohol and sodium alginate. The reason may be that the biological growth was inhibited by the high concentration of H2S17. Compared with Fig. 3(a and b), it can be found that the measured maximum EC of the CM-5 biofilter was much higher than that of the sterilized CM-5 biofilter. This result was mainly attributed to the functional microorganism communities because other conditions of the two biofilters were almost the same.

Overall, as the loading rate increased, the elimination capacities of CM-5 increased first and then showed a slight downward tendency. The ECs of CM-5 were much higher than those of sterilized CM-5.

Biodegradation kinetics

The pollutant elimination is mostly closely related to the microbial activity on the packing material surface, which could be described using biodegradation kinetics. The modified Michaelis-Menten model is commonly used to describe the relationship between the elimination behaviour and substrate concentration. This model mainly contains two reaction phases: first-order reaction and zero-order reaction. When the EC presents inhibition, a Haldane model containing a substrate inhibition term might be used to describe the elimination behaviour22. ECmax could be deduced from Ks, EC′,  and Ki, and these parameters could be calculated via the regressions of Cin, Cout, LR and EC according to eqs (1) and (2)22 (definitions of Ks, EC′,

and Ki, and these parameters could be calculated via the regressions of Cin, Cout, LR and EC according to eqs (1) and (2)22 (definitions of Ks, EC′,  , Ki, Cin, Cout, LR and EC can be found in Supplementary Table S1):

, Ki, Cin, Cout, LR and EC can be found in Supplementary Table S1):

Figure 4 shows the fitting results with the Haldane model and Michaelis-Menten model, respectively, based on data points of the CM-5 and sterilized CM-5 biofilters. Table 1 summarizes the biodegradation kinetics values calculated from the two models. The results show that the Michaelis-Menten model fit the experimental data satisfactorily, while the Haldane model fit the CM-5 biofilter data better because the Michaelis-Menten model does not consider the inhibition of the substrate. Actually, the high H2S concentration in waste gas would poison the microorganisms and decrease the purification efficiency. The result was partial in line with some previous literature22,23. As shown in Table 1, comparing ECmax based on the Michaelis-Menten model with that based on the Haldane model, it can be found that ECmax based on the Haldane model was slightly lower than that based on the Michaelis-Menten model for the two biofilters. It could be considered that there was a slight inhibition effect of the substrate on the microbial population for both CM-5 and sterilized CM-5 biofilters. Figure 3 also verified the substrate inhibition phenomenon, in which EC decreased when LR was higher than 80 g/(m3·h) and 30 g/(m3·h) for the CM-5 and sterilized CM-5 biofilters, respectively.

, Ki and ECmax).

, Ki and ECmax).In this study, ECmax obtained from the two models were approximately 62 and 8 g/(m3·h) for the CM-5 biofilter and sterilized CM-5 biofilter, respectively. The ECmax value of CM-5 was significantly higher than those reported in previous studies, as listed in Table 2. The ECmax values of CM-5 and sterilized CM-5 obtained in this experiment were low in comparison with other studies with polyurethane foam, sugarcane bagasse and coconut fibre1 but were compatible with results from mixed microbial population studies reported in the literature22. According to the report7, the rates of many industrial emissions were approximately 10–45 g/(m3·h) in production processes. Therefore, it could be inferred that the packing material of CM-5 might be applied in actual industrial operation. The packing bed could be used in modular format, allowing the use of as many modules as necessary so that the outlet gas could achieve a minimum concentration under the condition of permission pressure drop.

Overall, there were slight inhibition effects of H2S on both the CM-5 and sterilized CM-5 biofilters during the test. The Haldane model fit the experimental data better than the Michaelis-Menten model. The calculated maximum ECs of the CM-5 biofilter were much higher than those of the sterilized CM-5 biofilter.

Methods

Packing materials preparation

The CM-5 with functional microorganism communities and the sterilized CM-5 without microorganisms were used to fill two identical biofilters, respectively. The CM-5 was self-developed in the laboratory using matured compost, porous perlite, cement, calcium carbonate (CaCO3), plant fibre (sieved from dry compost) and inorganic binder. The suitable proportions in mass of these raw materials were 17%, 18%, 18%, 13%, 7% and 27%, respectively. CaCO3 was used to inhibit large pH fluctuations and matured compost was used as the nutrient sources. The functional microbial communities embedded in the CM-5 were obtained from a biofilter filled with corncob materials, which was used to remove the waste gas containing H2S. More information regarding materials or substances used in the preparation of CM-5 can be found in our previous paper12. The sterilized CM-5 was obtained by placing CM-5 in an autoclave for high-pressure sterilization for 30 min at 121 °C. This material was columnar and its surface looked rough. The appearances of the original CM-5 and the sterilized CM-5 can be found in Supplementary Fig. S1. Some selected characteristics of the CM-5 compared with single and synthetic materials from other studies are presented in Table 3. Clearly, the physical properties were comparable with most of the reference materials, illustrating that CM-5 might be suitable for application in a biofilter.

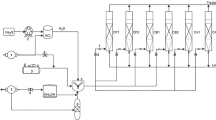

Experimental set-up

Two identical three-stage biofilters constructed using polyvinyl chloride (PVC) pipes were used in this study. The schematic diagram of the experimental system can be found in Supplementary Fig. S2. A 20-cm space above each packing layer was set to allow for air flow redistribution. The two biofilters were filled with 20.1 litres of CM-5 and sterilized CM-5, respectively. From bottom to top, the three sections were filled with packing materials to a height of 40 cm, 30 cm, and 30 cm, respectively. Four sampling ports were located along the wall of the biofilter for gas sampling and pressure measurements. Their locations were inlets, 15 cm above every packing layer, and outlets. Detailed information regarding the system can be found in our previous papers12,19. Operating conditions of the two biofilters are summarized in Table 4.

Mixed air was introduced at the bottom of the two biofilters directly. The H2S concentration, controlled by two gas flowmeters, was generated by mixing pure H2S from a gas cylinder and fresh air in a mix chamber. H2S concentrations were detected using a GT901-H2S device (accuracy: 0.1 ppm, Shenzhen, China). During the operation process, no biomass or nutritive solution was introduced into the biofilters artificially. The system was operated at room temperature throughout the experiment. To simulate the interruption of a biofilter occasionally occurring due to either mechanical or electrical failures in actual operation, a seven-day interruption was set at the 40th day.

Moisture content of the packing materials was measured by taking the materials out randomly from the biofilter and placing them in an oven at 105 °C until the weight remained stable. More information regarding the moisture content measurement can be found in our previous paper12. The moisture content of the packing bed was controlled at a certain level (40–60%) by spraying tap water from the top. The leachate was collected at the bottom and recirculated to the top by a peristaltic pump. The circulating water was sprayed for 15 min (approximately 3 L) every day. Note that the spraying period was 15 min every 4 hour during the first day. The pH was not adjusted artificially during the experiment because the CM-5 contained alkaline matters, which could neutralize the acidity produced by H2S. No other microorganisms in the two biofilters were inoculated, except for the microorganisms embedded in the CM-5 and the native ones contained in the water or air. To determine the quantity of microorganisms forming on the packing materials, granules were sampled from each module of the running biofilter homogeneously. Microbial amounts were measured using the plate count method12.

Pressure drops were measured during normal operation under the condition of no spraying water. The pressure drop was detected using a Testo 510 device (accuracy: ±0.05 hPa, Testo, Germany) under different gas flow rates. To describe load loss behaviour and compare with other studies, experimental data were processed according to the Ergun eq. (3):

where ΔP is the pressure drop along the packing materials’ bed length (Pa); L is the height of the packing material layer (m); V is the superficial air velocity (m/s); α (Pa·s/m2) and β (Pa·s2/m3) are the regression parameters23.

Several terms used to evaluate the performance of biofilters and the definitions of some parameters used to fit experimental data with the Michaelis-Menten model and Haldane model are displayed in Supplementary Table S123.

Additional Information

How to cite this article: Zhu, R. et al. Comparison of biological H2S removal characteristics between a composite packing material with and without functional microorganisms. Sci. Rep. 7, 42241; doi: 10.1038/srep42241 (2017).

Publisher's note: Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

References

Filho, J. L. R. P., Sader, L. T., Damianovic, M. H. R. Z., Foresti, E. & Silva, E. L. Performance evaluation of packing materials in the removal of hydrogen sulphide in gas-phase biofilters: Polyurethane foam, sugarcane bagasse, and coconut fibre. Chem. Eng. J. 158, 441–450 (2010).

Cox, H. H. J. & Deshusses, M. A. Co-treatment of H2S and toluene in a biotrickling filter. Chem. Eng. J. 87, 101–110 (2002).

Ma, Y., Zhao, J. & Yang, B. Removal of H2S in waste gases by an activated carbon bioreactor. Int.Biodeter. Biodegr. 57, 93–98 (2006).

Dumont, E. & Andrès, Y. Evaluation of innovative packing materials for the biodegradation of H2S: a comparative study. J. Chem. Technol. Biot. 85, 429–434 (2010).

Chan, W.-C. & Lin, Z.-Y. A Synthetic Filter Material Containing Nutrients for Biofilter. J. Polym. Environ. 14, 157–164 (2006).

Andres, Y., Dumont, E., Le Cloirec, P. & Ramirez-Lopez, E. Wood bark as packing material in a biofilter used in air treatment. Environ. Technol. 27, 1297–1302 (2007).

Elias, A., Barona, A., Arreguy, A., Rios, J., Aranguiz, I. & Penas, J. Evaluation of a packing material for the biodegradation of H2S and product analysis. Process. Biochem. 37, 813–820 (2002).

Chan, W.-C. & Lu, M.-C. A New Type Synthetic Filter Material for Biofilter: Preparation and its Characteristic Analysis. J. Polym. Environ. 13, 7–17 (2005).

Gutiérrez-Acosta, O. B., Arriaga, S., Escobar-Barrios, V. A., Casas-Flores, S. & Almendarez- Camarillo, A. Performance of innovative PU-foam and natural fiber-based composites for the biofiltration of a mixture of volatile organic compounds by a fungal biofilm. J. Hazard. Mater. 201, 202–208, (2012).

Oh, D. I., Song, J., Hwang, S. J. & Kim, J. Y. Effects of adsorptive properties of biofilter packing materials on toluene removal. J. Hazard. Mater. 170, 144–150 (2009).

Maestre, J. P., Gamisans, X., Gabriel, D. & Lafuente, J. Fungal biofilters for toluene biofiltration: evaluation of the performance with four packing materials under different operating conditions. Chemosphere. 67, 684–692 (2007).

Zhu, R., Li, S., Wu, Z. & Dumont, É. Performance evaluation of a slow-release packing material-embedded functional microorganisms for biofiltration. Environ Technol. 28, 1–11 (2016).

Liang, Y., Quan, X., Chen, J., Chung, J. S., Sung, J. Y., Chen, S. et al. Long-term results of ammonia removal and transformation by biofiltration. J. Hazard. Mater. 80, 259–269 (2000).

Hort, C., Gracy, S., Platel, V. & Moynault, L. Evaluation of sewage sludge and yard waste compost as a biofilter media for the removal of ammonia and volatile organic sulfur compounds (VOSCs). Chem. Eng. J. 152, 44–53 (2009).

Dumont, E., Guzman, L. M. A., Susa, M. S. R. & Andrès, Y. H2S biofiltration using expanded schist as packing material: performance evaluation and packed-bed tortuosity assessment. J. Chem. Technol. Biot. 87, 725–731 (2012).

Lu, C., Lin, M. R. & Wey, I. Removal of acrylonitrile and styrene mixtures from waste gases by a trickle-bed air biofilter. Bioprocess. Biosyst. Eng. 25, 61–67 (2002).

Chan, W.-C. & Ho, S.-J. A new type of poly(vinyl alcohol)/nitrocellulose/granular activated carbon/KNO3 composite bead used as a biofilter material. J. Polym. Res. 18, 1871–1877 (2011).

JiaDe, W., ShunLi, J., JianMeng, C. & YuRen, W. Performance evaluation of a slow-release composite media for biofiltration. SCIENTIA SINICA Chimica. 40, 1874–1879 (2010).

Zhu, R., Li, S., Bao, X. & Zhang, Y. Evaluation of new type of synthetic filler for the removal of NOx. Asian J. Chem. 27, 361–364 (2015).

Moe, W. M. & Qi, B. Performance of a fungal biofilter treating gas-phase solvent mixtures during intermittent loading. Water Res. 38, 2258–2267 (2004).

Kim, J. H., Rene, E. R. & Park, H. S. Biological oxidation of hydrogen sulfide under steady and transient state conditions in an immobilized cell biofilter. Bioresoure Technol. 99, 583–588 (2008).

Hernandez, A. C. R., Susa, M. S. R., Andres, Y. & Dumont, E. Steady- and transient-state H2S biofiltration using expanded schist as packing material. New Biotechnol. 30, 210–219 (2013).

Dumont, E., Andrès, Y., Le Cloirec, P. & Gaudin, F. Evaluation of a new packing material for H2S removed by biofiltration. Biochem. Eng. J. 42, 120–127 (2008).

Oyarzun, P., Arancibia, F., Canales, C. & Aroca, G. E. Biofiltration of high concentration of hydrogen sulphide using Thiobacillus thioparus . Process Biochem. 39, 165–170 (2003).

Galera, M. M., Cho, E., Tuuguu, E., Park, S. J., Lee, C. & Chung, W. J. Effects of pollutant concentration ratio on the simultaneous removal of NH3, H2S and toluene gases using rock wool-compost biofilter. J. Hazard. Mater. 152, 624–631 (2008).

Roshani, B., Torkian, A., Aslani, H. & Dehghanzadeh, R. Bed mixing and leachate recycling strategies to overcome pressure drop buildup in the biofiltration of hydrogen sulfide. Bioresour. Technol. 109, 26–30 (2012).

Courtois, A., Andres, Y. & Dumont, E. H2S biofiltration using expanded schist as packing material: influence of packed bed configurations at constant EBRT. J. Chem. Technol. Biot. 90, 50–56 (2015).

Gaudin, F., Andres, Y. & Le Cloirec, P. Packing material formulation for odorous emission biofiltration. Chemosphere 70, 958–966 (2008).

Shareefdeen, Z., Herner, B., Webb, D. & Wilson, S. Hydrogen sulfide (H2S) removal in synthetic media biofilters. Environ. Prog. 22, 207–213 (2003).

Acknowledgements

The authors would like to acknowledge the support of the National Natural science Foundation of China (No. U1304216) and the Research Fund of young scholars for the Doctoral Program of Higher Education of China (No. 20124101120015).

Author information

Authors and Affiliations

Contributions

S.L. and R.Z. conceived the experiments. R.Z. carried out the experiments and analysed the data. R.Z. and E.D. made the dynamic analysis. R.Z. drafted the manuscript, which was critically commented by S.L., X.B. and E.D. All authors reviewed the manuscript.

Corresponding authors

Ethics declarations

Competing interests

The authors declare no competing financial interests.

Supplementary information

Rights and permissions

This work is licensed under a Creative Commons Attribution 4.0 International License. The images or other third party material in this article are included in the article’s Creative Commons license, unless indicated otherwise in the credit line; if the material is not included under the Creative Commons license, users will need to obtain permission from the license holder to reproduce the material. To view a copy of this license, visit http://creativecommons.org/licenses/by/4.0/

About this article

Cite this article

Zhu, R., Li, S., Bao, X. et al. Comparison of biological H2S removal characteristics between a composite packing material with and without functional microorganisms. Sci Rep 7, 42241 (2017). https://doi.org/10.1038/srep42241

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/srep42241

- Springer Nature Limited